January

2021

|

Search the FOA website

FOA

Home Page Contact

Us

|

Sign

up for the FOA eMail Newsletter

Privacy

Policy

Sections

News

Technical Worth

Reading Q&A

Training/FiberU

Resoures

Safety

About

|

- In

This Issue

- Note

we have changed the format to place articles in

sections on one topic and all articles are dated so

you know if we repeat one - whcih we often do when

we think it's very important!

2021

Update

OJT-To-Cert

A Perfect Score

Last Gasp For Multimode Fiber

The "Father of Fiber Optics"

Newsletter

Sections

Click

on any link to jump to that section

News

TIA-568

Revisions

SENKO MPO Tester

Statistics On US Labor In Telecom

More

Technical

Lasers & LEDs, Total internal reflection , Loss Budget

Calculator

Worth

Reading Lots

of interesting articles

Q&A

Questions from our readers

Training/FiberU

New Fiber U MiniCourses, schools, remote OTDR

for training, making training classroom safe, onine

training, materials, more

Resources

New FOA YouTube Videos. Safety

About

FOA Certifications:

Time

To Renew Your FOA Certifications?

Special

offer - 1/3 Off Renewal

Jobs

- See

FOA Jobs

Web Page and FOA on

- The

FOA Jobs

Web Page has been updated and a new page added on Using

your FOA Training/Certification to Find the Right Job

in Fiber Optics

Where

Are The Jobs In Fiber Optics? FOA talks about all the

applications for fiber optics, what jobs involve and the

qualifications for the workers in the field in this YouTube

video.

Join

The FOA eMail Newsletter List

Want to

be notified when the FOA Newsletter is updated? Sign

up for the FOA eMail Newsletter. You can also

sign up from your cell phone: text "FOA" to 22828 (usual

text message charges apply)

Trademarks:

The FOA CFOT® (Certified Fiber Optic Technician) and

Fiber U® (the FOA online self-study program) are registered

trademarks of the FOA.

Want

to know more about fiber optics? Study

for FOA certifications? Free

Self-Study Programs are on "Fiber

U®." Looking for specific information? Here's the

largest technical reference on the web: The

FOA Online Fiber Optic Reference Guide.

Free

online self-study programs on many fiber optics and cabling

topics are available at Fiber

U, FOA's online web-based training website.

FOA

Reference Books

Available Printed or eBooks

The

fiber book is available in Spanish and French

Lennie

and Uncle

Ted's Guides are now also available as free iBooks on

iTunes.

Click

on any of the books to learn more.

- Fiber

Optic Safety Poster to download and print

FOA

Videos on

FOA

is a member of:

The

FOA Newsletter is edited by Jim Hayes - send your stories,

leads, ideas, comments to <jim @ foa.org>

Search

the FOA Website With DuckDuckGo

- The

Archives: Past Issues.

- Use

these links to read past issues or use FOA's

Custom Search to look for specific topics on our

website.

1/21,

1/20,

2/20, 3/20.

4/20, 5/20,

6/20, 7/20,

8/20, 9/20,

10/20, 11/20,

12/20,

1/19,

2/19, 3/19,

4/19,

5/19, 6/19,

7/19, 8/19,

9/19, 10/19,

11/19,

12/19

1/18,

2/18, 3/18,

4/18, 5/18, 6/18,

7/18, 8/18,

9/18, 10/18,

12/18.

1/17,

2/17, 3/17,

4/17, 5/17,

6/17, 7/17,

8/17, 9/17,

10/17, 11/17,

12/17

1/16,

2/16, 3/16,

4/16,

5/16, 6/16,

7-8/16, 9/16,

10/16, 11/16,

12/16

1/15,

2/15, 3/15,

4/15, 5/15,

6/15, 7/15,

8/15, 9/15

, 10/15,

11/15 , 12/15

1/14,

2/14, 3/14,

4/14, 5/14,

6/14, 7/14,

8/14, 9/14,

10/14, 11/14,

12/14

1/13,

2/13, 3/13,

4/13, 5/13,

6/13, 7/13,

8/13, 9/13,

10/13, 11/13,

12/13

1/12

, 2/12, 3/12,

4/12, 6/12,

7/12, 8/12,

9/12, 10/12,

11/12, 12/12

1/11

, 2/11,

3/11,

4/11,

6/11, 7/11,

8/11, 9/11,

10/11, 11/11,

12/11,

1/10

, 2/10,

3/10, 4/10,

05/10,

07/10,

08/10, 09/10,

10/10,

11/10

1/09

, 2/09,

3/09, 04/09,

05/09,

07/09,

08/09, 09/09,

10/09, 11/09,

12/09

1/08

, 2/08, 3/08,

4/08, 5/08,

6/08, 7/08,

8/08, 09/08, 10/08,

11/08, 12/08

12/07 , 11/07,

10/07, 09/07,

08/07, 07/07,

06/07, 05/07,

04/07, 03/07,

2/07, 1/07

12/06

, 11/06, 10/06,

09/06, 8/06,

7/06, 6/06,

5/06, 4/06,

3/06, 2/06,

1/06,

12/05

,11/05, 10/05,

09/05, 08/05,

07/05, 6/05,

5/05, 4/05,

2/05, 01/05,

12/04

, 10/04, 9/04,

8/04, 7/04,

6/04, 5/04,

4/04, 3/04,

1/04,

12/03

, 11/03 10/03

9/03, 8/03,

7/03, 6/03,

3/03, 10/02

, 8/02, 5/02

Current Issue of FOA Newsletter

Time

To Renew Your FOA Certifications?

To keep

your FOA certifications active, you need to renew them when

they expire. Now we have a new more convenient way to renew

- an online store at Paypal - where you can quickly and

conveniently use your PayPal account or your credit card to

renew your certifications.

- You

can now renew with PayPal or a credit card

-

PayPal

is available worldwide

Join

FOA On Social Media

FOA has

four LinkedIn Groups

FOA

- official page on LinkedIn

FOA

- covers FOA, technology and jobs in the fiber optic

marketplace

FOA

Fiber Optic Training - open to all, covers fiber optic

technology and training topics

Grupo

de La Asociación de Fibra Óptica FOA (Español)

SPECIAL

OFFER - 1/3 Off Your Certification Renewal Cost

In the

near future, there will be a requirement for continuing

education to renew your FOA certifications. FOA is testing

an option for renewals where you take a short Fiber U online

course.

If you would like to help FOA test this option, you can save

1/3 the cost of your renewal. Go

here to take the Fiber U CFOT Renewal Course: |

FOA

Newsletter - Features

Best

Wishes For A Happy And Prosperous 2021!

Last

year we started out our January Newsletter saying:

"But

Watch Out For This Year... We're only a few days into the

New Year and all we can say is the outlook is uncertain."

Well

!

Little did we know what was in store for us in 2020! We

don't need to review the past year, but it did teach

everyone a few lessons.

The Internet Works

We learned that the Internet is a necessity, not a luxury,

as many people stayed home from school or work and depended

on their Internet. We learned that the internet is robust;

it withstood the daily onslaught of videoconferencing and

data transfers from home with few glitches. Some areas even

seemed to get upgrades in service without asking.

But it soon became apparent that many people had inadequate

or no Internet - perhaps 40 million in the US alone. The

primary groups affected were students. Employees working

from home were generally Internet savvy people who would not

live somewhere without adequate Internet service. But

students are different. Many were from low income urban

rural areas where traditional service providers have not

built out services because it is costly and doesn't have the

payback of rich urban and suburban areas. Besides the

largest service providers were too engrossed in the

entertainment business, promoting their online movies or

funding documentaries on the joys of 5G - or was that just a

science fiction B movie?

What people learned this year was if you wanted Internet or

better Internet or even cheaper Internet, you better

do-it-yourself. And based on the large numbers who have

called FOA for advice this year, that is where the action

will be for the foreseeable future.

Training Adapted

FOA

schools around the world faced a big problem - how to

train people in fiber optics under restrictions of numbers

of people gathering, social distancing, sharing equipment

and working while wearing masks. We all learned a lot this

year. Schools rearranged classrooms to allow students to

work alone with sufficient distance between them.

Instructors spent a lot of time developing visual aids and

one even was able to set up test equipment that could be

shared on students smartphones or tablets. One instructor

told us he spent much of his time simply cleaning and

sanitizing desks and equipment.

Blended learning went mainstream this year. Schools have

been using Fiber U online courses like the Basics of Fiber

Optics to prepare their students to attend a regular class

so they can spend more time in the lab. This year the online

courses with help from instructors and videoconferencing

replaced the classroom work in many classes. Students needed

to come to class just for the hands-on work, shortening the

time in required to be attending class in person.

FOA even started beta testing remote labs with some of our

schools. Schools send their students equipment and

components then use visual aids created by FOA and

videoconferencing to teach hands-on skills and verify the

students skills over videoconferencing links. With remote

labs, students can get FOA certification training at home or

in their office without attending a class at a school. This

has some other advantages, as we've seen the need to train

people in hard to reach places such as on ships, in remote

locations like the Arctic or Antarctic, or anywhere you can

get a satellite Internet connection. (International Space

Station perhaps?)

For those interested in special topics, Fiber

U added ten new "Minicourses" that you can take in an

hour or less but completely cover an important topic for

fiber techs. Topics included some very basic ones like "dB"

or loss budgets, as very important ones like cable bend

radius, midspan access and fiber

optic network restoration.

The complexities of adapting to the pandemic took FOA and

our schools some time to adapt, so, as expected, we saw a

drop in the numbers of new FOA CFOTs this year, down about

1/3 from the year before.We had a big year for working techs

coming to FOA for our direct "Work-to-Cert" program and

contractors asking FOA about training new employees which

led to FOA developing a "OJT-to-Cert" program too.

FOA continues to grow and we've seen a big increase in

interest in fiber optics from those organizations who have

decided they must do it themselves if they want to build

fiber networks to provide Internet to their area.

OJT To Cert

As we said above, contractors needing to train new employees

as fiber optic technicians often had no local schools

offering classes because of restrictions on groups, so they

asked us what they can do until in-person training becomes

available. We always recommend that novices start with the

Fiber U Basics of Fiber Optics online self-study course,

covering the knowledge part of the FOA

KSAs. If they are working with a contractor doing OJT,

their mentor/supervisor should have a program to teach them

the hands-on skills which they will use in the field - on

the job.

FOA has been working with several contractors to set up a

comprehensive OJT-to-Cert

program, adding in the Fiber U Basic Skills Lab. The Basic

Skills Lab gives the the overview of all the installation

practices the will learn, providing basic instruction and

hints on how to do them correctly. Then they can be

allowed to use company equipment already knowing how it's

supposed to be done, speeding up the learning process.

The reason we call this program "OJT-to-Cert" is that

novices can become trainees and then, when they have field

experience, get CFOT certified by FOA. And since they have

specific learning goals to achieve, they can become CFOTs

in significantly less time that working on their own.

A

Perfect Test Score And Some Feedback

Over

the holidays, CFOT Steven McCauley chose to take the FOA

CFOT renewal course and save 1/3 on his CFOT renewal. What's

unusual was Steven got a perfect score! We almost never have

anyone get a prefect score on any FOA tests or exams, so we

sent him an email of congratulations. Here is his reply

which he kindly gave us permission to reprint here:

"Thank you!! I thought the test was pretty good. There were

a couple of tricky questions that I almost changed my

answers on, but I am glad now that I didn't. I don't often

get a perfect score. In addition to reading and studying the

two lessons linked in the renewal email I went back and

reviewed all of the end of chapter review questions from

your Study Guide to FOA Certification and read up on

anything that I had questions on. I would estimate that I

spent about 6-8 hours total over the long Xmas weekend in

preparation. I thought the two lessons linked to in the

renewal email did a nice job of explaining dB/dBm and the

associated +/- signs (or lack of) was helpful,

especially for those who might not work with decibels on a

regular basis. I have a background in RF and antennas so it

was a good refresher. Also, I think the explanation of

the 1, 2, and 3 cable tests in the linked Lesson 2 was

nicely done. I think I have a much better understanding of

the difference(s) and the reasons for those differences now.

All in all, I don't think anyone who puts forth a little bit

of effort will have much of a problem with the

recertification test."

In the future, FOA will be requiring a short refresher

course and test like this for renewal, so we've been

offering a discount on CFOT

renewal for those who will take the test now and help

us develop a proper exam. Thank you Steven and again,

congratulations!

The

Last Gasp For Multimode Fiber?

Cost

now favors singlemode, even in equipment/transceivers

The

decision between multimode and singlemode fiber has been

argued for years. This year, we have evidence the matter

should be decided and discussion closed.

Multimode fiber has maintained some market share for years

because of one simple fact - multimode transceivers and

equipment were cheaper than singlemode. Everybody knows MM

bandwidth is limited, even as higher bandwidth versions

(OM3/4) have made it possible to get above 10Gb/s for

short links in buildings. But to reach 100Gb/s, the

current standard for data centers and the goal of some

LANs, you need to use parallel optics with 8 or 20 fibers

(12 or 24 in reality because MPO array connectors are set

up for 12 fiber rows.) Sure there is a fiber for short

wavlength WDM (OM5) but it has not been welcomed by most

users.

Projects like the Open Compute Project for data centers

had driven down the cost of singlemode transceivers so

singlemode dominates there because speeds are already at

100G and above. But this year, FTTH technology and, most

importantly, astronomically high volume, has flowed down

to everyday transceivers and media converters.

We first became aware of this from two FOA instructors.

One sent us some of the "spam" emails he was getting from

suppliers in China. FTTH ONTs were being offered for less

than $10 each. This is a terminal for FTTH that transmits

bidirectionally over one fiber and converts GPON to

Ethernet, phone and video for the home. We started reading

our junk mail and found the same thing. The second

instructor told us he was buying Ethernet to fiber media

media converters off Amazon so cheap he was bundling them

with tools (also off Amazon) and sending out to people

interested in a do-it-yourself fiber optic course.

We started searching Amazon, eBay and other websites like

Alibaba to see what we could find. We bought several

Gigabit Ethernet media converters for less than $30 each -

$60 per pair to make a link - and singlemode versions were

several dollars cheaper than multimode.

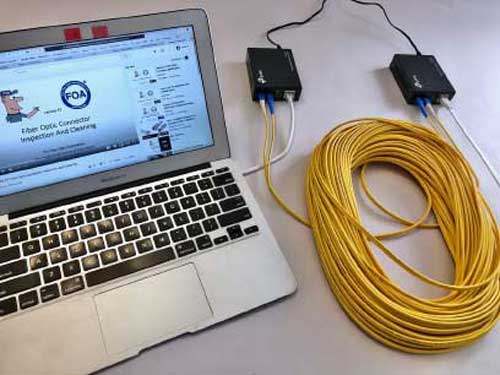

We set up a demo data link with these media converters

from our cable modem to a laptop to test it. We also

checked the power level, about -7dBm. The link worked

perfectly.

Of course so did the multimode versions of the same

product we bought, but remember they cost several dollars

more and the cable was also higher priced.

That was in the Spring of 2020. For a long time these were

the least expensive media converters we could find.

Recently, however, we bought a pair of singlemode

single-fiber bidirectional 10/100M media converters (not

gigabit, but fast enough for most applications) for $22.

However we had to spend an additional $15 for two power

supplies that were not included with the converters. But

that's still amazingly low cost - $37 for the electronics

to build a singlemode link.

Media converters are useful to convert Ethernet or other

electronic signals to fiber, but most network electronics

use some form of pluggable module like the "SFP."

Searching for SFP modules, we found them for gigabit

Ethernet at $124 for a pack of 10 for MM, $114 for SM, or

about $11-12 each and $1 each cheaper for SM. At

10G, MM was just slightly cheaper, ~$20-30 compared to

~$25-50 for SM. Note,

all these products had 5-star customer ratings, primarily

from IT users.

Why?

The cost of practically any product depends on the cost to

make something and the market for its sales. Low volume

means things are harder to produce, equipment that must be

amortized over the product lifetime adds more cost to each

unit manufactured and sold. Things made in high volume not

only amortize the cost of production equipment faster but

the volume means that it is easier to determine how to

make them and make them reliable. If the sales volume is

high, the cost of sales per unit is lower and customers

expect to get a volume discount on price.

Start with multimode and singlemode fiber. Multimode fiber

sales are only a few percent of the total fiber market

since it's use is primarily premises cabling. The volume

for OSP cabling, not just in length but average number of

fibers per cable, is enormously higher. Then there is the

complexity of the core of multimode graded index fiber

with hundreds or thousands of layers to create the graded

index core of fiber with higher bandwidth which causes

which makes it harder to manufacture and uses more

expensive materials.

The limited bandwidth of multimode fiber has led to a

"brute force" solution for higher speeds - parallel fibers

in a link, requiring 8 or 20 fibers to make a 100G link

(12 or 24 fibers if you use regular 12-fiber array

connectors.) And the connectors to use in these links are

not easily field terminated so one must design a system

carefully and purchase a complete cable plant. Needless to

say, something custom built is expensive, although it

reduces the cost of installation.

Singlemode fiber has a simpler structure and higher

volume, so it's cheaper. One market researcher I know says

it's "cheaper than kite string and fishing line."

The big difference in MM and SM networks has been the cost

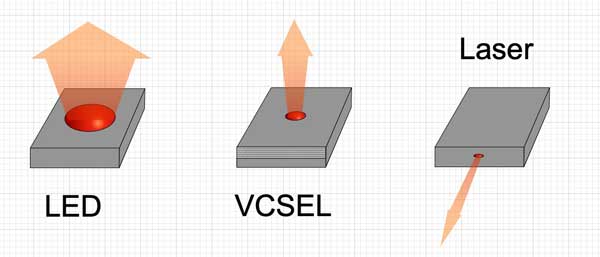

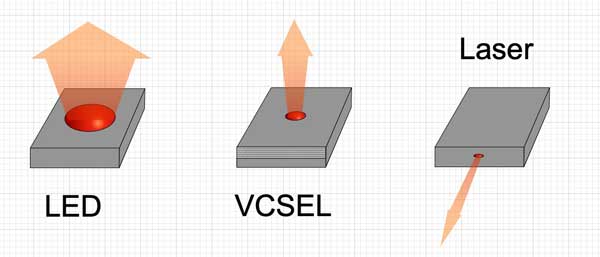

of transceivers. MM started with LEDs and went to 850nm

VCSELs at 1G and above. VCSELs were in the early days more

expensive than LEDs but less expensive that SM lasers. For

decades researchers have been trying to make 1310 nm

VCSELs for SM fiber but the physics is against them.

However, the simple Fabry-Perot singlemode laser has been

made for four decades and the volume used in FTTH has

driven the price down to be comparable with 850nm VCSELs.

Above 25G, SM can use wavelength division multiplexing to

achieve 100G and above on 2 fibers. Attempts to make SM

WDM work with 850-950nm VCSELs and OM5 wideband fiber have

worked but the acceptance by manufacturers and users seems

lacking.

Today, SM electronics are comparable or cheaper to MM

electronics, cabling is cheaper. SM has the ability to be

upgraded to terabit networks, MM, not so much.

And remember that passive optical LANs based on FTTH PONs

are more cost effective for premises LANs - using SM

fiber.

MM Won't Go Away

We don't expect to see MM fiber disappear; it has too much

history and momentum, plus lots of advocates selling MM

products. But the argument that MM is cheaper than SM is

harder to make these days, and if you try to decipher the

polarity of MPO for parallel optics (see News section below)

you will certainly appreciate the simplicity of SM fiber.

Upgrades? No question.

Narinder

Kapany, "The Father Of Fiber Optics" 1926-2020

Photo courtesy UCSC

Photo courtesy UCSC

Narinder Singh Kapany who coined the term "fiber optics" in

an article in Scientific American magazine in 1960, died in

December. Kapany, as a graduate student at Imperial College

in London working under Harold Hopkins, was the first person

to demonstrate how to use fiber optics in bundles to

transmit light. In the decade following his first successful

results in 1954 he was an author or co-author of 56

scientific papers on the subject and wrote the first book

published on the topic.

Dr. Kapany was more than a scientist, he was an

entrepreneur, educator and evangelist for this new

technology. He started two companies, Optics Technology in

1960, Kaptron in 1973 (acquired by AMP in the late

1990s) and K2 Optronics (with his sone Raj) in 1999.

During the 1980s, it seemed that Dr. Kapany was at every

conference on fiber optics, at least the ones I (JH) was

attending. He was an person you could hardly fail to notice,

elegant dress topped by his turban, enthusiastically

promoting the technology, encouraging investment and R&D

to help bring this new technology to commercialization.

He retained his academic roots, teaching at the University

of California at Santa Cruz and endowing chairs at several

other UC schools in optics, entrepreneurship and Sikh

studies.

His research and inventions have encompassed other

technologies beyond fiber-optics communications: lasers,

biomedical instrumentation, solar energy, and pollution

monitoring. He earned over 120 patents,

Some have said that Dr. Kapany deserved the Nobel Prize

given to Dr. Charles Kao. But one could also argue that a

Nobel Prize for fiber optics should be shared with others

from Bell Labs, Corning and several other organizations that

pioneered the technology.

Read more from UC

Santa Cruz and Santa

Cruz Tech Beat.

FOA

Newsletter Sections

News

Technical Worth

Reading Q&A

Training/FiberU

Resoures

Safety

About

|

News

|

April

Fools Day Coming Early This Year?

Or

just somebody trying to top the wild claims about 5G?

The

article does make one serious comment:

"In their view, the setting of hard targets for connectivity

speed has brought little payoff for operators while

lumbering them with multi-billion-dollar bills for the

rollout of more advanced networks. By simply cranking up the

bitrate or cutting latency, each successive generation looks

even less like a breakthrough and more like a mere evolution

of mobile technology. "

Well, isn't that what it is? Nobody has come up with a way

to make more money for carriers as new uses for cellular

communications put the burden on them to offer more

bandwidth.

Read

it in Light Reading

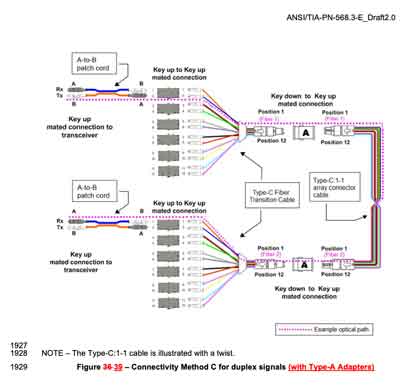

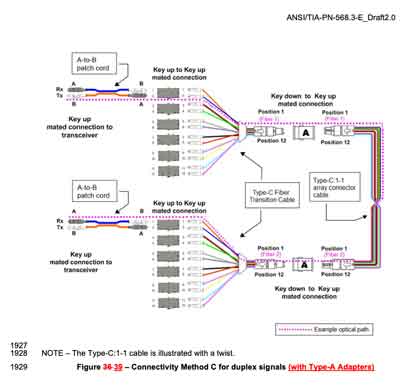

TIA-568

Revision: MPO Polarity Standards Expand To 38 Pages

The TIA

standard for fiber optic cabling in premises applications,

TIA-568.3, is up for its 5th revision (TIA-568.3-E) and has

many changes, most of which were expected. Three fibers,

OS1, OM1 and OM2 are no longer included although they are

mentioned as being "grandfathered," which means that these

components which have been part of the standard for decades

are now described as " grandfathered content recognized as

compliant, but not recommended for new installations."

As

usual, there are a few new definitions, some of which are

puzzling. A splitter, as used in a passive OLAN, is

officially designated as a "non-wavelength-selective passive

optical branching component." Or "optical fiber: Any

filament made of dielectric materials that guides"

Other

changes include changing TIA fiber component standards to

comply with ISO/IEC designations; not a problem since the

TIA designations (e.g. ANSI/TIA-492AAAA, -492AAAB, -492AAAC,

-492AAAD, and -492AAAE) were confusing at best. Also added

were bend-insensitive fibers and OM5 wideband fiber. Another

change makes sense, we suppose, as all illustrations and

references to single fiber/duplex connectors are changed

from "SC" to "LC." The MPO is used as the example for

"array" or multi-fiber connectors.

The standard contains no less than 38 pages devoted to the

MPO array connector, up from about 23 pages in earlier

editions. There are also at least 34 drawings and even more

tables. MPO is important, of course, but incredibly complex.

The MPO is the de facto standard for array connectors used

in prefabricated cabling systems and parallel optics for

multimode links over 10G. The problem is that there are 3

variations of connector/fiber polarity which leads to

multiple options for connecting various types of cables and

breakouts to single fiber or duplex LC or SC connectors. (See

the FOA page here for an explanation of MPOs.)

The

complexity of the MPO explains why you might need the gadget

below.

This tester verifies polarity for MPO cable assemblies and

identifies types A, B and C polarity cables. Let brian

Teague of SENKO explain it to you in their video at https://youtu.be/PoHJkkslkiQ.The

datasheet

is here.

SENKO knows about the complexity of the MPO. On this

page about MPO polarity, they say "The installer must

have deep knowledge of the equipment and their positions to

perform a correct connection."

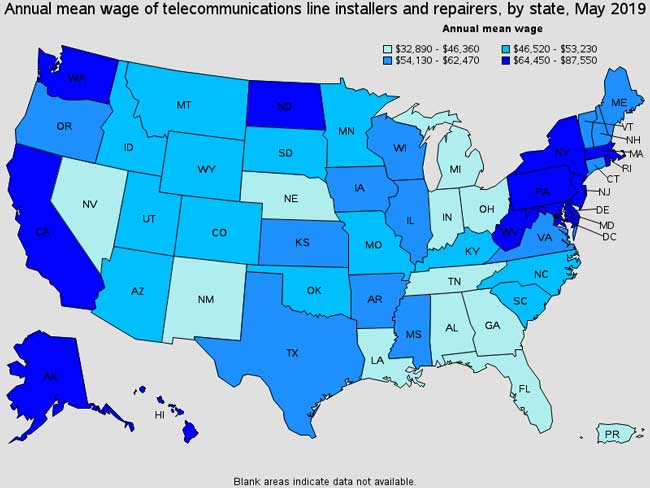

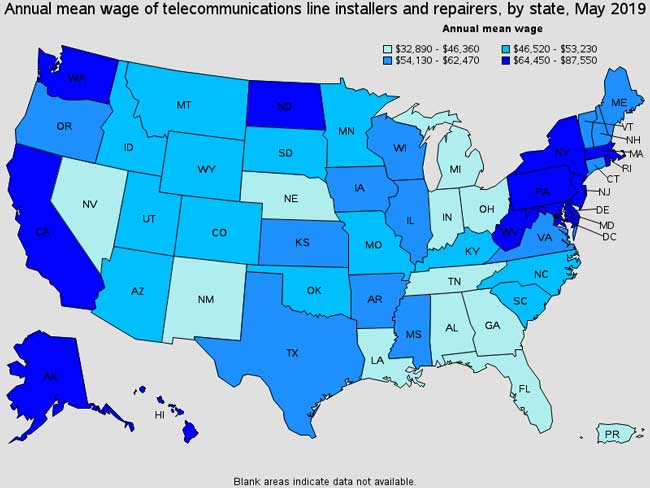

Statistics

on US Labor In Telecom

Eric

Pearson sent us some links to US Bureau of Labor Statistics

data on the US Workforce. Granted it was updated in May

2019, but has lots of useful and interesting information on

where the work is and what workers are paid.

Read

the reports here:

Telecommunications

Line Installers and Repairers (Install and

repair telecommunications cable, including fiber optics.

Telecommunications

Equipment Installers and Repairers (Install,

set up, rearrange, or remove switching, distribution,

routing, and dialing equipment used in central offices or

headends. Service or repair telephone, cable television,

Internet, and other communications equipment on customers’

property. May install communications equipment or

communications wiring in buildings.

Recycling

Fiber Optic Cable - Contact:

Steve Maginnis

LD4Recycle/ CommuniCom Recycling

(Visit

website)

sm@LD4Recycle.com

803.371.5436 |

Technical

On

fiber optic technology, standards, equipment,

installation, etc.

The

FOA Update Page

covers all the new technology and applications we covered

in this newsletter recently. Now you can review all that

new tech at once.

Want

to know more about fiber optics? Study

for FOA certifications? Free

Self-Study Programs are on "Fiber

U®." Looking for specific information? Here's the

largest technical reference on the web: The

FOA Online Fiber Optic Reference Guide.

|

Fiber

Optic Sources For Transmitters

FOA has

added a new page to its online

reference Guide on laser

and LED sources for fiber optic transmitters. The

types of sources used in fiber optic transmitters are

determined by a number of factors including the speed of

transmission and the distance needed over the link. It's

also tied to the types of fiber being used, affecting

coupling to the fiber and the preferred wavelengths of

transmission. This page in the FOA Guide covers the types of

sources and their characteristics that make them appropriate

for each application.

Sources

For Fiber Optic Transmitters - LEDs And Lasers

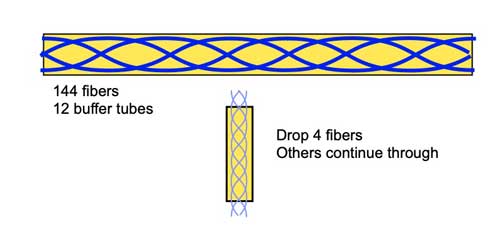

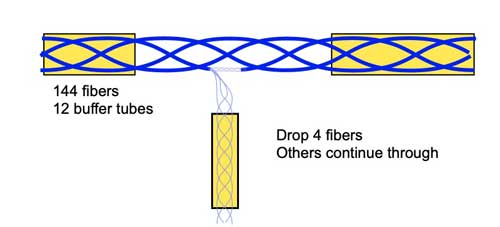

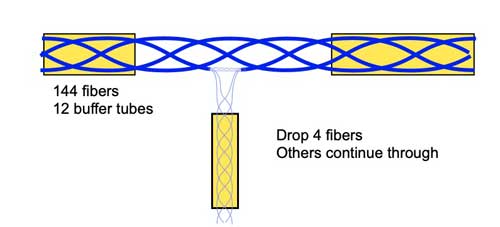

Midspan

Access - Simplifying Installation Of Drops

Technical

questions we get here at FOA often remind us of things many

of us take for granted that are not known by many installers

and particularly network owners and users. Recently we

received an email like this from a network owner working

with a contractor on a 15mile (25km) cable plant with

roughly 17 locations where cable drops were needed:

"Can the quantity of fiber optic fusion splices and splice

enclosures please be confirmed? For 192F cable, there should

be 194 splices per splice case at each site where a 4F drop

cable is installed."

Neither the user nor his contractor knew about midspan

access. We figured that probably meant that lots of other

people don't know about it either, so we decided to cover it

in this newsletter, add a page to the FOA Guide and maybe

even make a Fiber U MiniCourse about it.

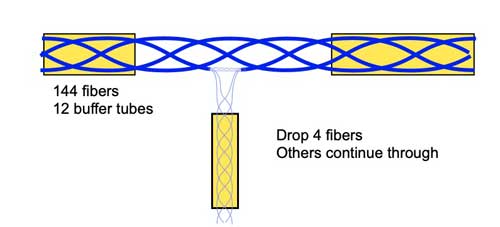

Here is an example:

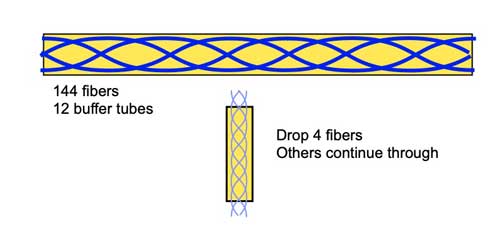

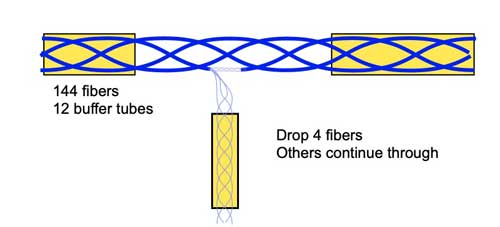

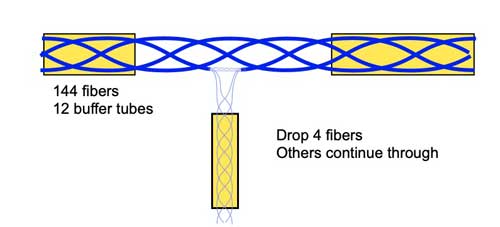

Many installations involve dropping a small fiber count

cable from a large backbone cable. Backbone cables of

144-288 fibers are common and larger ones are becoming more

common too. Drop cables are often only 2-14 fibers, meaning

most fibers are continuing straight through the drop point.

Midspan access involves opening the cable by removing the

jacket and strength members, opening the buffer tube and

splicing only the fibers being dropped at that point. The

untouched buffer tubes from the opened cable are carefully

rolled up and stored in the same splice closure as the

fibers that will be separated and spliced to a drop cable.

If there is a method of splicing only the 4 drop fibers

instead of the 144 fibers, we will only have 4 splices

instead of 144 or 146 depending on the architecture of our

system. The difference is according to how the drop is

configured.

If you are building a star network where every drop links

back to the origin of the network, you will splice 4 fibers

in the cable to the drop cable, leaving 4 splices on 4

fibers (instead of 144 splices if the backbone cable is cut

and respliced.

If you are building a ring network, you may only be splicing

two fibers going to the drop and two others that are

continuing along the ring network.

All this may seem obvious but in actual practice requires

some knowledge, skills and careful workmanship. To do a

proper job. Fortunately, manufacturers of cables and tools

have good information available online on how to do it, and

FOA Master Instructor Joe Botha has provided FOA with a application

note on how midspan access is done in his classes

also.

The basic process is simple. We will look at a loose tube

cable but processes exist for ribbon cables also. You remove

the jacket of the cable for a specified length according to

the cable type and splice closures used. After removing the

cable jacket, you remove unnecessary strength members,

leaving enough of the stiff central member on both ends to

attach to the splice closure. Identify the tube with the

fibers to be spliced to the drop cable and set aside while

carefully coiling the other tubes for storage in the

closure.

To open the buffer tube, you need a midspan access tube that

shaves off a section of the tube to allow removal of the

fibers without damaging them. Here two types of Miller tools

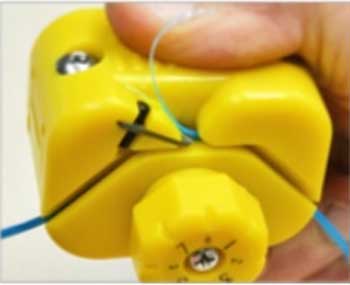

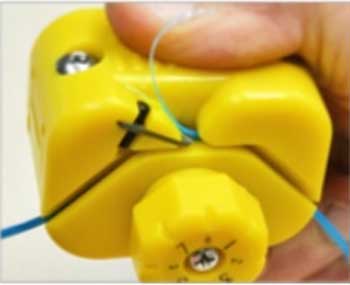

that shave the tube:

After

shaving the tube and removing the fibers - count carefully

to ensure you remove all the fibers! - you can cut the tube

off to have bare fibers only for the length you need to

splice on the drop cable. All these fibers will be placed in

a splice tray for safe storage but only the fibers being

dropped will be cut and spliced to the drop cable. This is

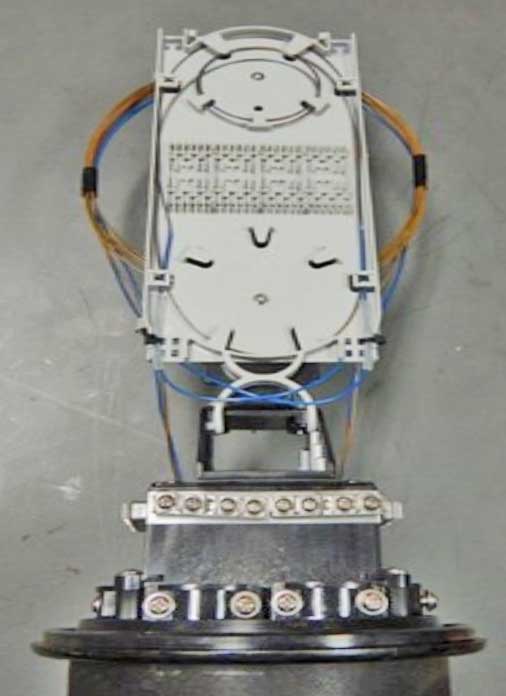

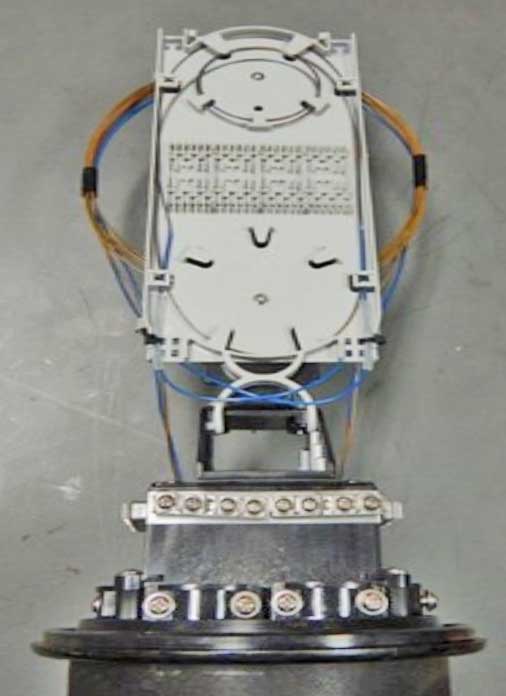

what the closure will look like, ready for splicing the drop

cable.

In the

case of the particular user who contacted us, not every drop

would use midspan access. His cable plant was 15miles (25km)

long with roughly 17 locations where cable drops were

needed. The cable he was using could only be made in 5km

lengths, so there would have to be several locations where

the cable would be spliced in the 25km run.

The design would need to carefully determine how much cable

was needed along each section of the route, including

lengths for service loops and midspan access or splicing, to

determine which drop points would be using midspan access

ans which would be used as splice points for the entire

cable.

That's why fiber optic network design is important but

sometimes complicated.

Search online for "midspan access" to find lots of

application notes and videos on the subject. Or talk to your

fiber optic cable vendors.

FOA

Guide Page on Midspan Access

Try

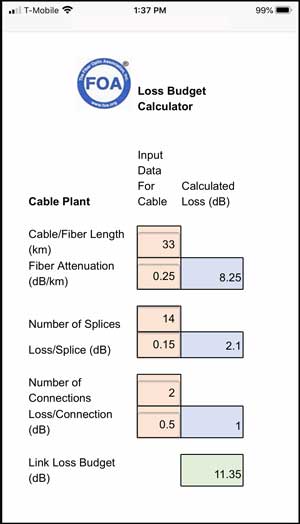

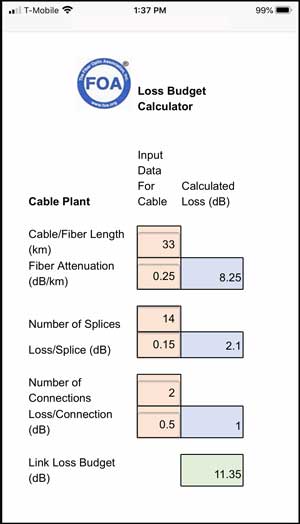

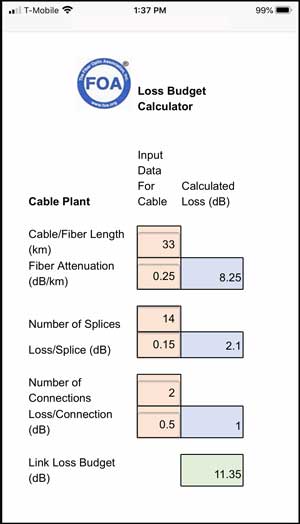

The FOA's New Online Loss Budget Calculator

FOA has

written many articles about loss budgets, something everyone

involved in fiber optics needs to know and needs to know how

to calculate. We've created a online Loss Budget Calculator

that does the work for you. Just input your cable plant data

and it calculates the loss budget. It works on any device,

especially smartphones and tablets for field use and even

allows printing the results.

Bookmark

this page (especially on your smartphone): FOA

Loss Budget Calculator Online

Splice-On

Connector Manufacturers and Tradenames

7/2020

FOA Master Instructor Eric Pearson of Pearson

Technologies shared a list he has researched of

prepolished splice connectors with mechanical splices and

SOC - splice-on connectors for fusion splicing. This list

shows how widepread the availability of these connectors has

become, especially the SOCs and low cost fusion splicers.

Mechanical Splice

1. Corning Unicam® (50, 62.5, SM)

1. FIS Cheetah (???)

2. Panduit OptiCam® (50, 62.5, SM)

3. Commscope Quik II (50, 62.5, SM)

4. Cleerline SSF™ (50, SM)

5. LeGrand/Ortronics Infinium® (50, 62.5,

SM)

6. 3M/Corning CrimpLok (50, 62.5, SM)

7. Leviton FastCam© (50, 62.5, SM)

Fusion Splice

2. Inno (50, 62.5, SM)

3. Corning FuseLite® (50, SM)

4. FORC (50, 62.5, SM)

5. Siemon OptiFuse ™ (SM, MM)

6. Belden OptiMax?? FiberExpress (SM, MM)

7. AFL FuseConnect® (SM, MM)

8. OFS optics EZ!Fuse ™ (50, 62.5, SM)

9. Sumitomo Lynx2 Custom Fit® (50, 62.5,

SM)

10. Commscope Quik-Fuse (50, SM)

11. Ilsintech Pro, Swift® (50, 62.5, SM)

12. LeGrand/Ortronics Infinium® (50, 62.5,

SM)

13. Greenlee (50, 62.5, SM)

14. Hubbell Pro (50, SM)

15. Easysplicer (SM)

Note: There are additional manufacturers from the Peoples

Republic of China, which advertise on Amazon and eBay.

|

Worth

Reading

Each

month we read hundreds of newsletters and online articles.

These are the ones we think you will find "worth reading."

|

Worth

Reading: 01/2021

Making

Your Town Broadband Ready Even if you are not

ready to build your own fiber or FTTH network, there are

things you can do now to be ready when you make that

decision that will also help attract private investment.

This article is by Trevor Jones, Vice President of

Marketing, Sales and Customer service for OTELCO, which owns

independent telephone companies in seven states and partners

with several community networks in Massachusetts. Contact

him at trevor.jones@otelco.com. It offers good advice for

cities thinking about or needing fiber in their town.

(Broadband Communities)

Everstream

launches 5G fiber builds in seven Midwestern U.S. markets

Business-only fiber network services provider Everstream

says it plans to launch fiber cable deployments in seven

Midwest markets to support 5G mobile network requirements.

The company says the fiber networks will help to connect

more than 2,000 macro cell towers in those markets and offer

backhaul support. (Lightwave)

Infinera,

Facebook achieve 700-Gbps per wavelength transmission on

MAREA submarine cable In a “hero experiment”

scenario, a production version of an ICE6 module enabled

wavelength transmission of 700 Gbps over 6,640 km.

(Lightwave)

Removing

Roadblocks on Bridge Over Digital Divide: Explaining the

Affordable, Accessible Internet for All Act -

Reversing laws that prohibited government or public/private

broadband, mandating "Dig Once." ILSW Community Networks

Next

Century Cities Year in Review - Overview of progress

made in the last - eventful - year. Link is to a

Black&White version which is easier to read. The color

version is here.

Telcos’

tipping point: 10G Fiber and Software-Defined Access,

Dell'Oro Group/Adtran. The need to provision and

deliver new services in a matter of hours, as opposed to

weeks or months, holds just as much priority as the

ability to deliver up to 10Gbps of PON capacity.

12/2020

Dilbert's

Company Rolls Out 5G - DON"T MISS THIS!

Passive

Optical LAN shines in Cost Comparison - Lightwave

US

FCCs Rural Digital Opportunity Fund made awards of

>$9BUS to ISPs to deliver Internet. There was

jubilation and consternation. Reading these show what we

mean:

Case

Studies - Next Century Cities - state of broadband in

some US cities.

Fiber

Resource Shortages - Doug Dawson, President of CCG

Consulting sees shortages of labor and components in 2021

Terminating

an eposy/polish ST connector - Linden Photonics

shows how to make a reliable termination (excellent

visuals show how it's done)

AFL

Splice Closure For High Density Cables - up to 3456

fibers (video)

Can

one of the architects of AT&T’s woes turn it around?

Uncool

can beat flashy tech - NY Times. Balloon Internet

project by Google's parent Alphabet hits snags, remote

areas wonder why it's needed - they have Internet on

old-tech mobile phones

Power

Delivery over Single-Pair Ethernet - TIA Webinar

recorded earlier.

Biden,

top Democrats lay groundwork for multibillion-dollar

push to boost U.S. broadband

Residents

Form Broadband Coop - “Electric

cooperatives worked, why can’t we do the same thing for

broadband?”

Saving

Lives through Education. Online, worldwide April 6-8, 2021.

The Excavation Safety Conference VIRTUAL brings critical

damage prevention education to help all stakeholder groups

online, providing new opportunities to network with industry

peers, learn safe practices, and lower costs associated with

underground damages. Register now at GlobalESCVirtual.com

Worth

Reading: 11/20

The

pandemic makes clear it’s time to treat the internet as

a utility - David Lazarus, Business, LA Times

Another

company (SpaceMobile) wants to load space with low earth

satellites - Light Reading

Chicago

And Denver Voters Say Yes to Expanded Broadband Options

- ILSR

10

Tips For Installing Fiber Optic Cable - Multilink

Why

the 5G pushiness? Because $$$. Shira Ovide, NYTimes

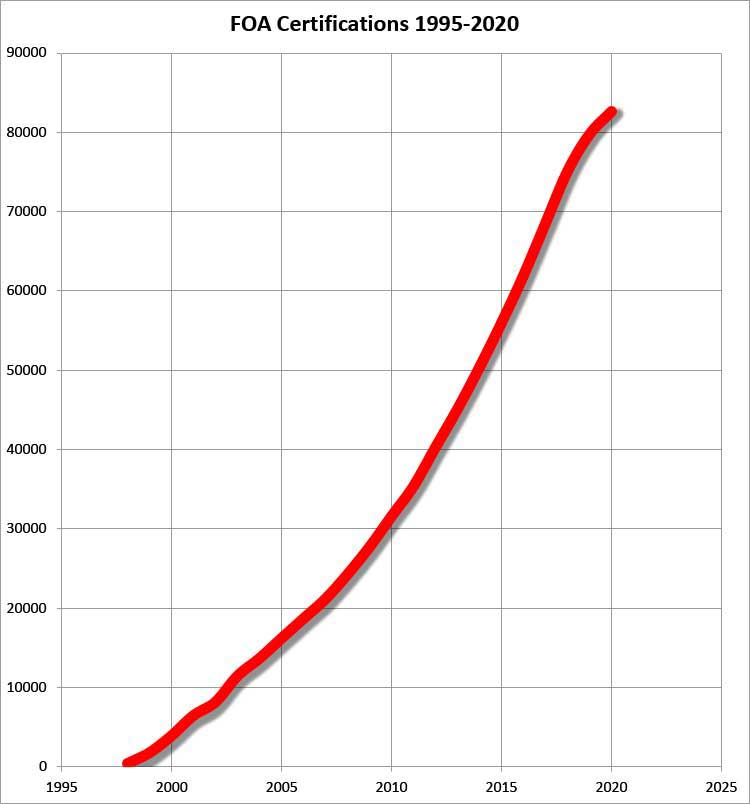

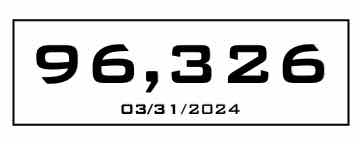

1995-2020

- FOA's 25th Anniversary!

As part

of celebrating 25 years of serving the fiber optic industry

as its primary source of technical information and

independent certifying body, FOA thought it appropriate to

create a short history of the organization and how it has

developed to help the fiber optic industry. We also

wanted to recognize the contributions many people have made

to the organization over the years that made FOA what it is

today.

The FOA history is now archived on the FOA website where

you can read it anytime or link to it.

Updated

info - dB, total internal reflection and science projects,

Worth

Reading - News Summary - Past Links Worth Repeating

If

you are interested in restoration - aren't we all? -

you should also read this article in dpPro magazine by

FOA President Jim Hayes: Damage

Protection Requies Looking Overheas As Well As

Underground - dpPRO Magazine - about the

problems with aerial cables. His previous article for

the magazine was New

Techniques for Fiber Optic Installation.

How

much fiber optic cable is manufactured each year?

CRU Reports - unsurprisingly China is by far the largest

market today

The

Institute

for Local Self-Reliance weekly newsletter has

lots of interesting articles and links.

The Open Technology Institute at New America just

published “The

Cost of Connectivity 2020,”

US

Ignite and Altman Solon issued “Broadband

Models for Unserved and Underserved Communities”

Universal

access to broadband is a cornerstone to a strong

economy, Achieving universal access will require

community partnerships. by Alfreda

B. Norman, Sr. VP, Federal Reserve Bank of Dallas

FIBER

TO THE FARM: The co-ops that electrified

Depression-era farms are now building rural internet. Be

sure to check out the high-tech equine installation

equipment.

Next

Century Cities Newsletter - News from cities

around the US including Detroit and New York plus small

Infrastructure

Get Some Respect, NY TImes "On Tech"

"The magic of the internet requires a lot of very boring

stuff behind the scenes. "

Pentagon

official: FCC decision on 5G threatens GPS, national

security

Internet

Statistics and Facts, 2020: Interesting, easy

to get lost here!

DIRT

Report On Damage To Utilities

Common Ground Alliance (CGA) annual DIRT report provides a

summary and analysis of the events submitted into CGA’s

Damage Information Reporting Tool (DIRT) for the year

2018. The complete report is available for download

here. In addition, there is an interactive

dashboard that allows users to filter the data

more by factors contributing to damages.

Structured

Cabling News - a website and weekly

newsletter about cabling.

The

Internet Master Plan for New York City.

The New York City Internet Master Plan is a

comprehensive framework for the infrastructure and

services that provide connectivity to New York City

residents and businesses. This Master Plan will guide

City actions and public-private partnerships to

transform New Yorkers’ access to this essential

infrastructure for generations to come.

Fiber

Trivia From Corning.

Why

understanding PoE now is crucial for electricians

- To ring in the new decade, IDEAL Networks is urging

today's electricians to master new skills and equipment to

cope with the growing use of PoE in intelligent lighting

applications.

Smart

City Projects: Smart city initiatives are

underway across the country. But they face funding and

technology challenges. Many cities want to upgrade

infrastructure to improve resident experience, safety and to

generate revenue.

The

Future Of Work Is Skills - So Stop Worrying About

Degrees - The

reality is the future of work is about skills, not just

degrees. (FOA Newsletter Feb 2020)

Want

a White-Collar Career Without College Debt? Become an

Apprentice (NYTimes)

Apprenticeships probably began with the first jobs, where

young people work under experienced craftspeople to learn

a trade. In the last century, they became more organized

under labor unions like the International Brotherhood of

Electrical Workers, one of the FOA's oldest and biggest

approved school systems. Today, apprenticeships are

expanding as young people look at viable alternatives to

loading themselves with debt while attending college.

The

job market is hot. So why are half of U.S. grads

missing out?

VIAVI

Books On Fiber Optic Testing (2 volumes) - They're back!

Besides

the FOA reference materials, two JDSU/VIAVI textbooks,

Reference Guide to Fiber Optic Testing, Volumes 1 and

2, were used as references for some of the FOA courses

and are recommended for instructors and students. The books

are available from VIAVI as eBooks and the everyone should

download them and recommend them to others.Download yours

now. Volume

1. Volume

2. Viavi Books

Guidebook

To MPO Testing OptoTest

offers this complete guide to MTP®/MPO testing. In this

guide, you will learn all there is to know about the

different test methods, equipment options,

troubleshooting, and best maintenance practices to ensure

that you have the best testing experience.

Go

here to download the book.

50th

Anniversary of The Development of Low Loss Fibers

A history of the development of low loss fiber, a

fascinating story by Jeff Hecht on the OSA (Optical Society

of America) website.

How

OFS Makes Fiber

Interesting YouTube video on how fiber is made. Perhaps a

little too much "show biz" but fascinating. If you have ever

seen fiber manufacture, look at this video. You will be

amazed at how big preforms have become!

How

Nexans Makes Copper Cables - compare the process

to fiber - don't most of the machines look similar?

The

True Cost of Telco Damages (what backhoe fade or

target practice can cost)

Rural

Electric Cooperatives: Pole Attachment Policies and

Issues, June 2019.

Clearfield-FOA

Certification Training Clearfield is now

offering their customers an FOA

CERTIFICATION course. This course provides

a basic understanding of fiber optic technology, as well

as Clearfield product knowledge and how Clearfield’s

integrated product systems work together in a fiber

network.

Substandard

Contractors - Fiber Optic Knowledge Doesn't Always

Trickle Down (EC Mag)

Another

Source Of Articles On Fiber

FOA

President and editor of this newsletter Jim Hayes has also

been writing a column in Electrical

Contractor Magazine for almost 20 years now.

Electrical contractors do lots of fiber work and this column

has covered some topics they are interested in including

installation processes, network design, fiber applications

and a lengthy series on dark fiber - what it is, how's its

used and how it benefits the growth of communication. A

recent web site redesign makes it easier to browse all these

articles - just go to http://www.ecmag.com/contributing-authors/jim-hayes

and you can see all of them. |

Q&A

Tech

Questions/Comments From FOA Newsletter Readers Worth

Repeating

The

FOA Fiber FAQs

Page (FAQs = frequently asked questions) gathers

up questions readers have asked us (which first ran in

this newsletter) and adds tech topics of general

interest.

|

Good

Question!

The

FOA Fiber FAQs

Page (FAQ s = frequently asked questions) gathers

up questions readers have asked us and adds tech topics

of general interest.

Questions

From FOA Newsletter Readers

January 2021

Maintaining

Dark Fiber

Q: Do you have any standards that speak to how often

dark fiber should be tested with OLTS and OTDR? Such as just

at installation and when troubleshooting, or should they be

done on a regular basis?

A: We at FOA know of no standards calling for

periodic testing of fiber optic cable plants.

Fiber optic networks generally do not require maintenance

and it is often detrimental to the network. It is the

opinion of FOA and most people in the industry that testing

should be done upon completion of the installation and data

submitted to confirm proper installation of the cable plant.

Data should then be stored for reference in case of problems

requiring troubleshooting or when new dark fibers are turned

up. Before lighting a dark fiber, it should be tested and

the results compared to earlier data. Since both tests have

some uncertainty, test results can vary as much as 0.5dB on

short cables, higher on longer runs.

If older fiber is being upgraded to higher speeds, now

cities like Santa Monica where we live are upgrading to 100G

networks, fiber characterization including chromatic

dispersion, polarization mode dispersion and spectral

attenuation (for DWDM) are advised. Of course, every time a

connection is opened, it should be inspected and cleaned.

And patchcords should be tested; even new ones in sealed

packages are often dirty. There is a reason people call the

plastic protective caps on connectors “dust caps!”

Otherwise, with fiber, we suggest the patch panels be locket

to keep unauthorized personnel from accessing them and

causing problems. Even disconnecting a connector can add

dirt to the connections and cause problems.

December 2020

Are FOA Videos and Web Up To Date?

Q:

Are the videos on YouTube still relevant by today's

standards are are they out of date?

A: Excellent question. We’ve discussed this within

the FOA many times.

For example the live action videos on cable preparation,

termination, mechanical and fusion splicing and testing are

quite old by tech standards but the processes have not

changed in two decades. Preparing loose tube, armored or

tight buffer cables has not changed in over 20 years, nor

has adhesive/polish connector termination.

Prepolished/splice connector and SOC process are different

and those processes have been updated. Testing processes are

the same with the main difference being the automating of

OTDR testing. Manufacturers have dumbed-down OTDRs so well

that it seems few techs know how they work or how to read a

trace, evidenced by the results of the FOA CFOT

Certification exam where questions on OTDRs are the most

often missed.

We just did a review of the copper installation for the

Premises cabling (CPCT Certification) and that has not

really changed in three decades - since the introduction of

Cat 5 cable!

We review and update the technical pages in the FOA Guide

all the time. Look at the Table of Contents (FOA Guide-https://foa.org/tech/ref/contents.html)

and see how many pages have the NEW symbol, indicating

updates in the last couple of months.

Also FOA is adding YouTube videos (https://foa.org/tech/ref/contents.html#YT

) and Fiber U MiniCourses (https://fiberu.org) on many

topics regularly - monthly this year, covering new tech and

the topics we know are lesser-known or new to most techs.

And let us know if there are topics you think we should

focus on in the future.

Microscope Power For Connector Inspection

Q: What

power microscope do you recommend to inspect

singlemode/multimode in 1.25/2.5 format (ST, SC, LC)?

A: Microscopes

in the range of 100-400 power are available. Many people

assume higher power is best - and it is for examining

polishing results in the center of the ferrule - but lower

power helps inspect more of the ferrule for dirt when used

in the field before connecting or testing cables. We prefer

the lower power.

So for patchcord manufacturers, 400, field techs 100.

Patchcord manufacturers will undoubtedly use video

microscopes, most field tech the optical ones.

November 2020

Loss For APC vs UPC Connectors

Q:

I was wondering if there will be a standard connector loss

for a UPC connector and a different lower value for an APC

connector.. ex. upc has 0.5dB while APC is 0.3dB.

I would like to make all connectors uniform on a new network

infra to avoid mismatch and causing any possible damage on

the equipment when APC will be plugged into to a flat.

A: There is really no statistical difference between

APC and UPC connector loss. The lower reflectance of the APC

actually reduces loss since the reflectance represents a

factor in connection loss, This issue of connector grades

has been discussed at international standards committees for

years. ISO/IEC wants to have grades of connectors, rated for

connector loss in ranges from 0.1 to 1dB, but I do not think

it’s standardized. I recommend using 0.3-0.5dB for loss

budgets, where in OSP networks it matters little, since

there are only a few connections and fiber and splice loss

is a larger factor.

Keeping UPC and APC connectors straight is easy - APCs are

Green, UPCs are blue. Everybody just needs to be taught

that!

OTDRs - Launch Cables And Range

Q:

I have a question about OTDR launch cables. In

all readings about OTDR testing, it states that the launch

cable "needs to be of sufficient length ...". What

length is sufficient? How long should a launch cable

be? What is the maximum length of cable plant that can

be tested at one time?

A: OTDR launch cables need to be long enough to allow

the OTDR to settle down after the test pulse leaves the

instrument and reflectance at the output connector overloads

the receiver. The dead zone is a function of the OTDR test

pulse and the condition of the output connector. If you are

testing short cables (<1km) with very short test pulses,

a launch cable can be 20-50m long. If you are testing a very

long cable with very wide pulses (some OTDRs have pulses

~4microseconds long, equivalent to ~1km) you would need a

2-5km launch cable. So the answer to that question is it

depends on how long the fibers are you are testing.

As to how far a OTDR can reach, the answer is generally not

specified in km but in dB. The best OTDRs have a reach of

~40dB at 1550nm which corresponds to ~150-200km, spending on

how good the splices are. That length of fiber would have

~30 splices for say 3dB splice loss.

Here’s the FOA

Guide page on OTDR testing and the FAQs

page Frequently Asked Questions about OTDRs.

October 2020

Last month's article about the installation

of a 6912 fiber cable in small conduit prompted a

number of this month's questions on social media. And there

were more too.

Re: Installation

of a 6912 fiber cable

Q: For this post, "Tight Fit: 6912 Fiber Cable

Pulled in 1.25 inch Conduit”, he asks if they can see one

end completely terminated?

A: It takes about 2 full racks of patch panels or one

rack of splice trays. Sumitomo shows the splicing rack here

https://global-sei.com/data-center-solutions/splicing-rack.html.

Most systems using these cables will buy fully populated

patch panel racks with a splice rack for the cable to splice

to 6912 fibers terminated in the rack.

Q: And a second question:: How long does it take to

terminate? And over how many panels?

A: A very experienced tech can splice one of these

cables in ~75-100 hours using ribbon splicing.

Q: I assume that's smaller fiber like 80 micron

cladding

A: All the fibers in the high fiber count cables are

made with regular singlemode fiber - 9/125micron. TO make

the cables smaller, the buffer coating diameter is reduced

to ~200microns to make the fibers smaller.

Q: How was it prepared with the splice tray and ODF?

It might require a dedicated panel and splice tray.

A: It takes about 2 full racks of patch panels or one

rack of splice trays. Most systems using these cables will

buy fully populated patch panel racks with a splice rack for

the cable to splice to 6912 fibers terminated in the rack.

Q: Is this an actual photo or was the cable installed

in a different type conduit.

A: We were told that is the actual size of the cable

and conduit although not of the actual installation

discussed.

Q: What is the minimum bend radius of that cable?

What procedures did they use to maintain that bend radius

through those 90 degree curves?

A: The minimum bend radius is 15X the cable diameter

for that cable (diameter 1.14” or 29mm), about 17” or

435mm. The conduit bends had to be controlled to be larger

than that radius.

Jobs In The Movie Industry

Q: Does anyone know if there are job positions in the

film industry that involve fiber optics? I started out

working in film with audio work with some camera as well. I

eventually transitioned into fiber optics installation and

testing. I've been trying to find out if there's a way to

find work that combines the two.

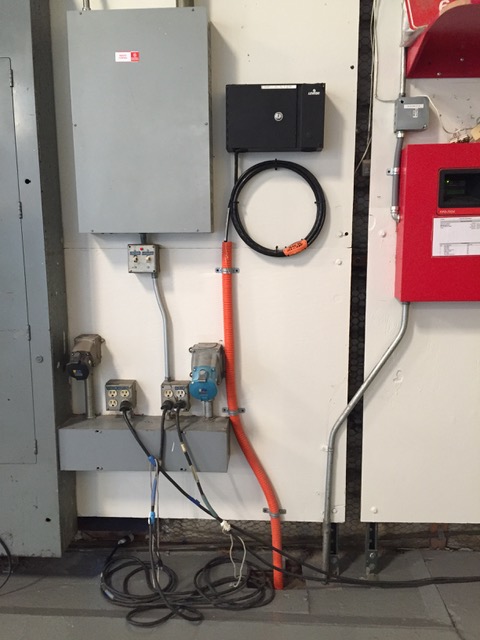

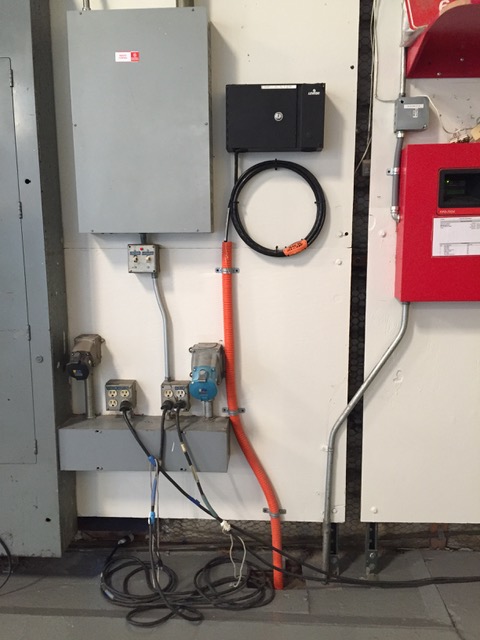

A: There are certainly jobs for fiber techs at the

film studios. We worked with a group 20 years ago to find

dark fiber in LA to connect studios to sound stages and

other facilities. Every studio now has fiber connections

everywhere, like this one at Paramount (below). I don’t know

where to look for jobs, but I’d guess it would be through

the unions - who represents the techs for the cameras,

monitors, etc.?

Preparing Cable For Splicing

Q: Is there any standard on the preparation length of

strip jacket upto the splice tray. Ideally its better to

have a loop of buffer before getting into the tray if ever

the closure has enough space for slack.. its also nice to

put some hose to the buffer to add on protection. So far, i

don't see any standard and can't support the remarks on what

to follow. The practice was to take note on macrobend and

have enough length of fiber to reach the machine.

A: There is a lot of variation in the size, shape

and design of splice closures, so the length varies

according to the closure and trays. For loose tube cable,

the length of buffer tube from the entrance to the splice

tray and the length of fiber needed in the tray are given in

the directions for that splice tray. Similarly for ribbon

cable, but the variations in ribbon cable designs often

requires special handling and sleeving for the ribbons. Most

manufacturers have specs available online.

Fusion Splice-On Connectors (SOCs) (From an FOA

Instructor)

Q: A question came up from one of our students

regarding splice on connectors. Is there a TIA or

other standards body that addresses this issue? We are used

to the 0.75 dB loss for a mated pair, however, when this

mated pair has two fusion splices that terminate the

connector, is there a recommendation?

One could make the argument that it does not make any

difference as the other alternative is splicing a pigtail

for termination of a cable. This pigtail splice is

normally included in the link loss budget

calculation. So similarly, with a splice on

connector it is the same as splicing on a pigtail.

A: There are no specific TIA or IEC specs that

address these splice-on connectors or pigtails. If you used

TIA numbers and included the splice and connector it would

be 1.05dB - 0.75dB for the connection and 0.3dB for the

splice, that’s mated to a factory adhesive/polish

connector. Or if it were two similar connectors,

1.35dB.

Everybody, including the people in TIA standards groups,

know those numbers are too high for most single ferrule

connectors. They keep them at 0.75dB for prepolished/splice

connectors (w/ mechanical splices) and array connectors

(MPOs) which have somewhat unpredictable performance.

Internationally, IEC has created grades of connectors from

~0.3 to over 1dB. The newer mechanical splice connector kits

now use the Chinese copied cleavers which are super - at

least the few we have tested - and the connectors are now

much lower loss and consistent.

SOCs (fusion splice-on connectors) are spec’ed as the total

termination and are generally just as good as the typical

adhesive polish connector - 0.5dB is plenty of margin for a

those mated to a factory adhesive/polish connector.

Spliced on pigtails are generally considered a termination

and the splice is not broken out - like a long SOC. But I

cannot guarantee everybody thinks that way. But a fusion

splice is typically <0.1dB anyway.

The

word on the "Dig Once" program is getting out - FOA is

getting calls from cities asking us for information and

advice. Here are some links:

The DoT page on the administration’s Executive Order: http://www.fhwa.dot.gov/policy/otps/exeorder.cfm

From the Council of State governments: http://www.csg.org/pubs/capitolideas/enews/cs41_1.aspx

From the city of San Francisco: http://sfgov.org/dt/dig-once

An article about Dakota County, MN: https://muninetworks.org/tags/tags/dig-once

And

the one to download and hand out:

A “How To” Guide from The Global Connect Initiative: https://share.america.gov/wp-content/uploads/2016/04/6.-GCI-Dig-Once.pdf

Fiber Optic Cable Plant - The Finished Product 4/2020

In

April, FOA received inquiries from several sources that all

deal with the same subject - what is involved in the

specification and acceptance of a cable plant at the end of

a installation project. And what are reasonable

specifications for a cable plant.

FOA has a lot of documentation on a project involving

designing and installing a cable plant in the

FOA Online Guide and our Textbooks, but the acceptance

process has usually been relegated to a few paragraphs. We

decided to add a page

on project "Deliverables" in the FOA Guide that covers

this topic in more depth. This page looks at a project, goes

into some depth on loss budgets and includes links to FOA

tech documents to help you investigate further.

Correction: In the article, the original list of fiber

specs for G.652 was wrong. It should be 0.4dB/km @ 1310nm.

Deliverables

in the FOA Guide

Is

There A Standard For Fiber Optic Installation?

Another

question we get often is "Is there a standard for fiber

optic installation." The answer is yes, but not from the

usual standards groups you might expect. Over 20 years ago,

the National Electrical Contractors Association (NECA) asked

FOA to help create a standard for installation. That

standard, ANSI/NECA/FOA-301 has been updated three times

already and is about ready for another update.

Unlike most of those groups who charge you a fortune for

standards, FOA covers the cost so ANSI/NECA/FOA-301

is available free from FOA.

Download

your free copy of ANSI/NECA/FOA-301

here (PDF)

Older

questions are now available here.

|

Training /

FiberU

News and resources to help you learn more and stay

updated.

Find

a listing of all the FOA-Approved schools here.

Free

online self-study programs on many fiber optics

and cabling topics are available at Fiber

U, FOA's online web-based training website.

Free

online training at Fiber U

The

FOA has >100 videos on  |

Two

More New Free Fiber U MiniCourses

Reading OTDR Traces And Midspan

Access

FOA has

created two more free Fiber U MiniCourses this month.

Reading

OTDR Traces

The second course this month covers one of the topics most

missed on CFOT certification exams - Reading

OTDR Traces. It's all about what elements are

displayed in an OTDR trace and what they represent. It's a

very different format from other Fiber U courses. OTDR

traces are visual, so it's a visual course where you learn

by "pointing and clicking" on a simulated OTDR trace, like

this:

Midspan

Access

As promised last month in our tech article on midspan

access, we took the new material created about Midspan

Access in fiber optic cable installation and

made that into a minicourse. This technique is fairly

widely used because it saves much time and cost in adding

drops to a fiber optic cable, but we've been surprised how

many techs are not familiar with it. The MiniCourse takes

only a little time, about right for a coffee break.

That makes 10 Fiber U MiniCourses, 5 Basics courses, 4

Skills courses, 1 Design course and 6 Applications courses -

26 free online self-study courses for everyone. And we have

lots more planned for the near future.

All Fiber U courses are free but there is a

nominal charge for the tests for a Certificate of Completion

to cover the cost of the online testing site we use. Most

online courses cost hundreds or thousands of $US, so we are

sometimes asked how FOA can offer free courses. The answer

is we have very low course development costs since we use

the FOA Guide's pages (almost 1,000 of them) and Videos

(over 100 on YouTube) and the courses are completely

self-study - no instructor to guide you and provide feedback

on your work. (And we do not track you.)

The Fiber U course method has been around for over two

decades and used by tens of thousands of people to

learn more about aspects of fiber optics or prepare for

their FOA certification exams. Since the reference material

for Fiber U is the same as used for training for FOA

certifications and for the certification exams themselves, Fiber

U courses are the ideal study guide for FOA

certifications.

More

New Fiber U MiniCourses

Got

An Hour Or Less? Learn Something New About Fiber Optics.

FOA has

introduced a new type of Fiber

U

course, the MiniCourse, a free online course you could take

in a short time, perhaps as you ate lunch at your desk or

took a coffee break. The

topics of these courses should explain what they are about,

and these are all very important topics to fiber optic

techs.

Fiber

Optics In Communications

Fiber

Optic Network Restoration

Fiber

Optic Connector Identification

The

Mysterious dB of Fiber Optics

Fiber

Optic Cable Bend Radius

Fiber

Optic Link Loss And Power Budgets

Fiber

Optic Connector Inspection And Cleaning

Fiber

Optic Media Conversion

Fiber

Optic Cable Midspan Access

Reading

An OTDR Trace

The courses have two components, video lectures and

readings, that are complementary. As usual there is a

self-test to allow you to check your comprehension. As with

other Fiber U courses if you desire, you can take a short

test for a Fiber U Certificate of Completion that costs

only $10.

All these free courses and many more are

available at Fiber

U.

New

FOA Schools

Welcome

Woodstock Job Corps, Woodstock, MD, School # 385

Welcome

To A New International School

What

Fiber Techs Don't Know -

What

We Learn From FOA Certification Tests

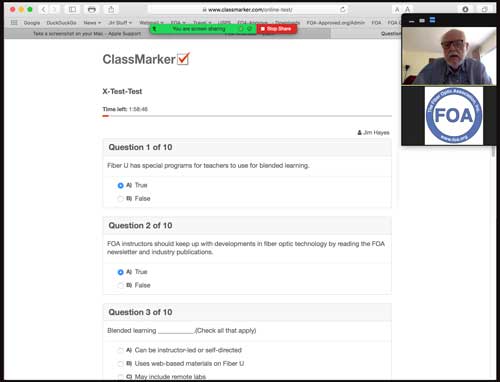

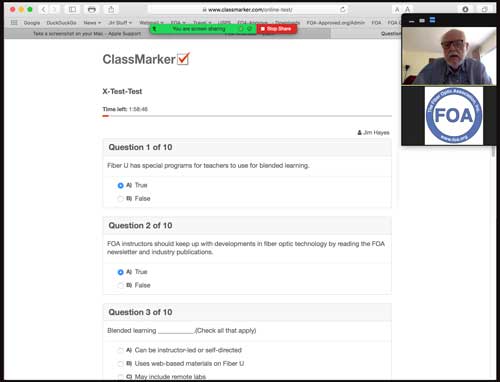

As FOA

moves more testing over to our digital online testing system

at ClassMarker, we have access to more data about our

testing, including what questions and topics on the tests

are answered incorrectly most often. Having this data gives

us an opportunity to evaluate the questions and how they are

stated, but more importantly it allow us to help our

instructors teach the subjects and us to change our

curriculum and online courses to emphasize these particular

topics. These are some of the topics that we have noticed

are answered incorrectly more often in FOA and Fiber U

tests.

Most of the questions missed are on testing.

1. OTDRs - particularly what information is in the OTDR

trace.

2. The difference between dB and dBm

3. Loss budgets - both the concepts and doing the math

4. Insertion loss testing - single-ended or double ended for

testing patchcords or cable plants, how to set 0dB

references

5. Units of measure - fiber is measured in microns,

wavelengths in nanometers, etc.

At FOA, we're working to add Fiber U

MiniCourses on these topics and working with our

schools to emphasize these topics in their classes.

If you are going to be taking a FOA certification course or

test in the near future, these topics should be on your

final exam study list.

What We Learn From Hands On Labs

We learn about students performance in hands-on labs from

the feedback of our instructors and our own experiences too.

One big problem is the use of hand tools. Growing up today,

you learn how to use keyboards, mouses and touch screens,

but decades ago, you also learned how to use basic hand

tools. This is big enough of a problem that we're

considering adding some video lessons on basic hand tools to

prepare students for cable prep, termination and splicing

that require the use of hand tools.

FOA

"Work-To-Cert" Program

Experience

Plus Online Study At Fiber U = FOA Certification

This

year, more techs have become comfortable with online

conferences, webinars and training. Many have discovered

that they can become FOA Certified using their experience in

fiber optics and study for the FOA certification exams

online at Fiber U.

Thousands

of industry professionals have applied to the FOA directly

for certification without the need for classroom training,

based on their knowledge and skills developed working the

field. Since FOA certifications are based on KSAs

(knowledge, skills and abilities), current techs already

show the skills and abilities required through their field

experience. FOA provides free online self-study

courses at Fiber U

for the knowledge part to prepare you for FOA certification

exams which you can also take online.

If you are an experienced field tech interested in

certification, and FOA is the internationally

recognized certifying body for fiber optics, you can find

out more about the FOA

"Work to Cert" program here.

If you are already a CFOT, FOA also offers many specialist

certifications you can obtain based on your experience as a

field tech. See what's available at Fiber

U.

Options

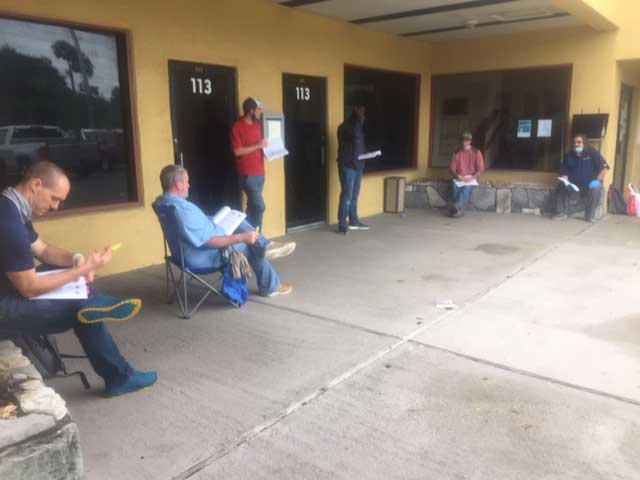

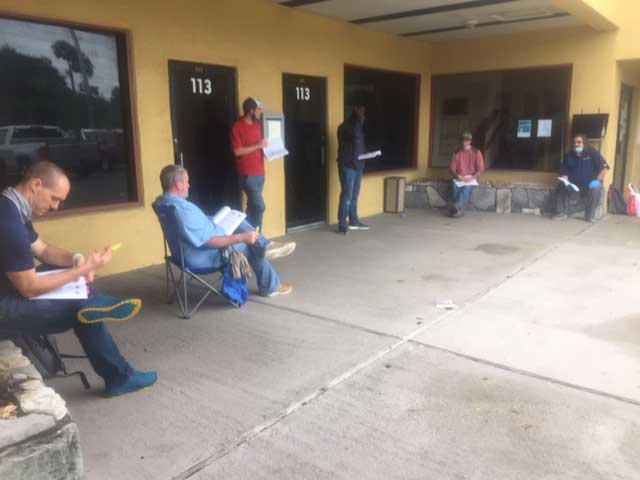

For Training Classes - Outdoors (11/2020)

Tom

Collins, Techtricians, FOA Director, keeps exploring new

ideas for training. This time, the course moved outdoors in

Daytona Beach, Florida. This solution works well as long as

it's warm and dry!

New

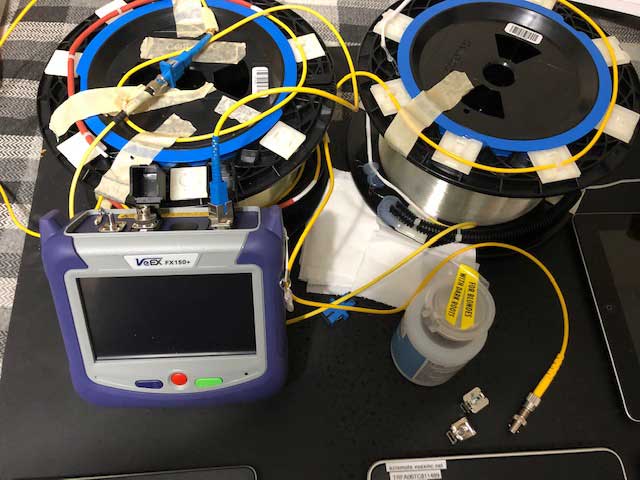

Approach To Fiber Optic Labs - Sharing Test Equipment

(10/2020)

Tom

Collins, Techtricians, FOA Director

Techtricians,

a FOA approved school, has taken a new approach in

how we provide lab training. Fifteen years ago, we developed

a hybrid training model had the participants complete online

(remote) lessons with face to face labs. Over the past 12

years trade organizations, colleges, vocational, vendor

training, and trade apprenticeships have adopted this model.

At the beginning of the pandemic we spent a lot of time,

energy, and money developing remote labs. We have

incorporated lessons learned from that process to restart

safe face to face labs.

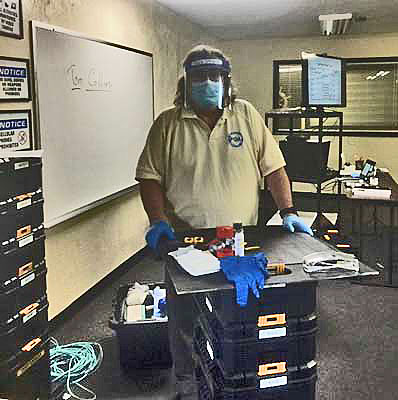

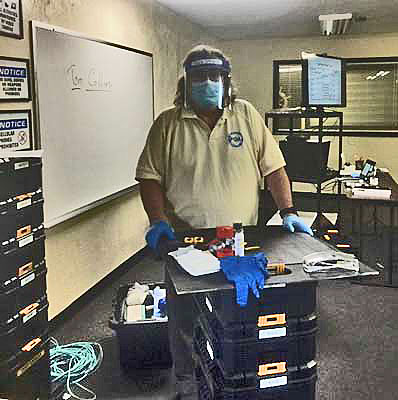

First, we provide disposable materials and PPE’s for all

learning. Every student has their own work space with 8-9

feet of separation and their own set of hand tools only used

by the student. All of the classroom information is accessed

online or with USB drives. Our biggest challenge was how to

safely share testing equipment so every student could have

the practical hands on experience.

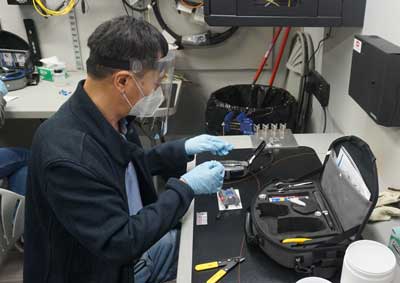

We believe we have found that solution with the help of “ezremote”.

The ezremote allows a multitude of students to have

practical exposure and experience with using a video

microscope, OLTS and OTDR testers. Every student can access

the remote via their own iPad or their smart phone, see

below picture and movie.

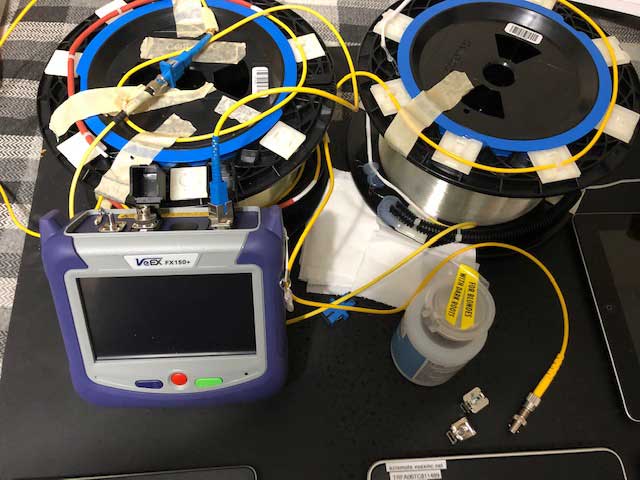

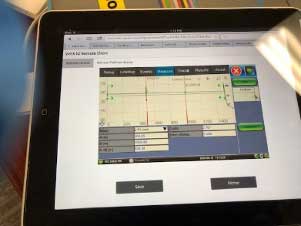

The VeEX OTDR set up for remote access in class

Recently, we contacted PCS, Inc. which is a premiere

manufacturer’s representative firm serving the Southeastern

US since 1974. Headquartered in Roswell, GA, Marc

Wright a sales representative spent a lot of time and

energy helping Techtricians to purchase the VeEX

FX150+ device. It is a full featured Mini OTDR with

high resolution sampling and intelligent link mapping for

Metro, Access and FTTx networks remote application. The

compact, lightweight platform incorporates built in WiFi,

power meter, light source, fiber inspection probe and VFL

test options which add exceptional versatility to the unit.

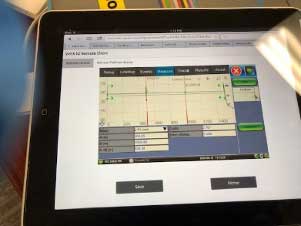

The remote OTDR displayed on an iPad (L) and on 4

smartphones and 2 laptops

In September we completed our first trial in a face to face

lab session in Lake Mary, Florida. The OTDR unit uses a WIFI

connection. The students went to the VeEX website with their

iPad or their smart phone and connected the to the base

unit. The lab module used one OTDR setup for the entire

class for testing the cable plant.

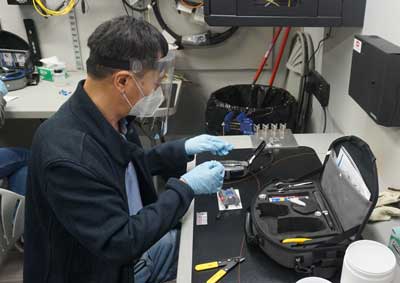

The instructor's laptop is connected to the OTDR and

projecting the display for everyone to see

The students when logged-in had control over the OTDR. Each

student saw the same screen which made the various events

much easier to explain. The module is very safe as the OTDR

is not touched by any student. The feedback we received from

the students was very positive. They provided suggestions

for future training modules. Even after the pandemic is

over, we will continue to use this new training method. Our

best teachers are our students and our hats are off to all

of our students.

For more information, contact Tom or Donna Collins at Techtricians.

FOA

School BDI

Datalynk is offering classroom training with Covid

precautions and remote classes over most of the US.

FOA

Master Instructor Eric Pearson of Pearson

Technologiesis now offering classroom training with