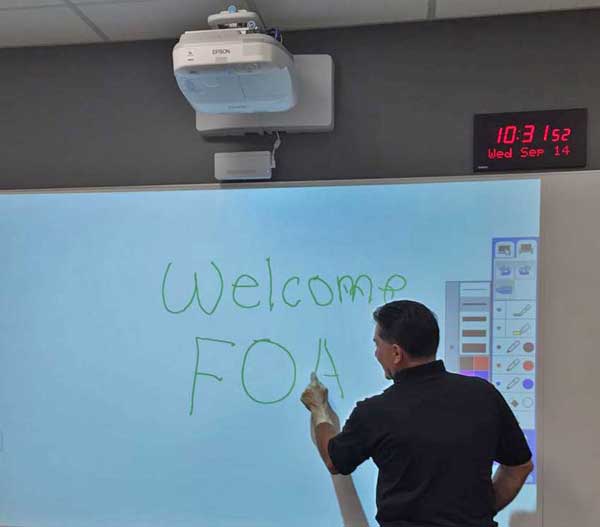

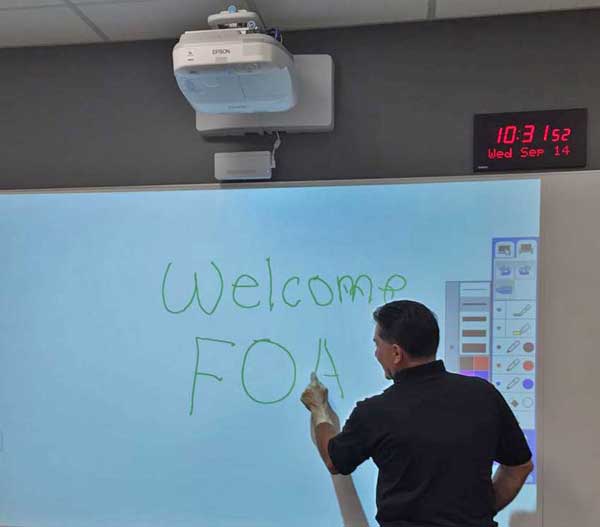

The

classrooms have new interactive projectors that have inputs from

PCs and finger-touch recognition that allows writing on the

board with your finger - none of those messy markers required.

NorCal

has a small studio that allows making their own videos for

training.

But they don't abandon older methods. Basil shows us drawings

used to train apprentices on reading and interpreting standard

paper drawings used on projects.

The most impressive part of the tour of this JATC facility is

the "Data Center."

Rather than hiding all their LAN, video and phone hardware, they

built it in a glassed-in room in their break/lunch room for

everyone to see. They have another touchscreen panel with a

digital version of the data center that allows virtual tours of

the equipment so visitors and students can see how all the

equipment fits into the high tech learning environment.

We won't show you the more conventional stuff - classrooms and

labs with equipment for training apprentices on voice, data and

video cabling and equipment - but it's equally impressive.

The San

Leandro JATC is, of course, located in Silicon Valley where

keeping up with technology is a full time job. The facility

provides a learning environment that allows students to see

what is being done in tech and takes them "backstage" to

learn how this technology is connected using fiber and

copper cabling and wireless.

FOA has been a training partner with the JATCs from our

beginning. Today 30

JATCs in the US use FOA programs to certify students

and the FOA has been training JATC instructors at their

annual summer National Training Institute for 20 years. They

even print their own version of the FOA textbook. We often

point out to people who call FOA asking about careers in

fiber optics that the JATCs offer an apprenticeship program

that allows you to learn the technology of voice, data and

video cabling while getting paid to work in the field.

We've visited many of the JATCs over the years and they all

have impressive training facilities, but the San

Leandro JATC is the most high tech, at least today!

Wideband

Multimode Fiber (WBMMF) Has A New Name - OM5

We

have discussed wideband multimode fiber in the FOA

newsletter several times in the last two years, This is a

modified OM4 fiber that has been modified to allow

wavelength division multiplexing with VCSELs in the range of

850 to 950nm. Recently the ISO/IEC standards committees

agreed to call it OM5 fiber. Next up is the discussion of

whether it gets a special color instead of using aqua like

OM3 and OM4 fiber. The current proposal is to use "lime

green" - that should make it stand out in cable trays!

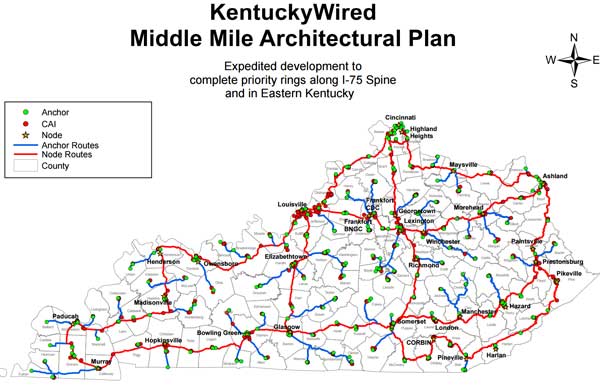

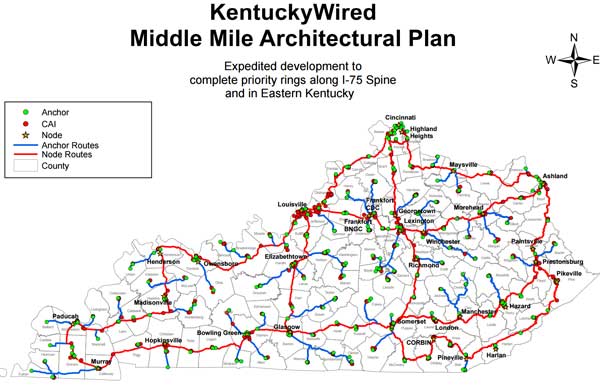

Kentucky

Wired Moving Forward In Eastern KY

The Kentucky

Wired broadband network is moving forward in eastern KY with

two new partners announced recently. The Kentucky

Communications Network Authority (KCNA), the entity overseeing

KentuckyWired, entered into strategic agreements with

Cincinnati Bell Telephone System (CBTS) and most recently with

East Kentucky Network LLC (EKN) to partner on broadband

network construction in north/central and eastern Kentucky.

The EKN partnership covers 21 counties in eastern Kentucky and

will tie into the main trunk line from northern Kentucky. The

Cincinnati Bell partnership is critical in that Cincinnati is

one of two key gateways—along with Louisville—to the worldwide

web points of presence. A presence in both Cincinnati and in

Louisville provides redundancy in case one site has issues.

Without these links, KentuckyWired would just be a network

within the state with no connections to the high-speed, high-

capacity Internet.

“Cincinnati Bell is pleased to partner with the State of

Kentucky on this important initiative,” said Gary Peddicord,

General Manager, Carrier Services, for Cincinnati Bell.

“Cincinnati Bell has a long history of supporting economic

development efforts in the communities we serve, and broadband

connectivity is a key part of creating jobs and opportunity in

Kentucky.”

“EKN partner companies have been in business more than 60

years,” said Allen Gillum, CEO and General Manager of EKN. “We

are happy to be a part of KentuckyWired and to bring our

experience and resources to this important project.”

These agreements highlight KCNA’s ongoing commitment to work

with existing infrastructure companies to efficiently and

economically improve broadband services in the Commonwealth.

Additional strategic partnership discussions are currently

underway throughout the Commonwealth.

The KentuckyWired middle-mile network, a

public-private-partnership with the Macquarie Group, will

consist of more than 3,000 miles of fiber optic cable and more

than 1,000 government and post- secondary education sites that

will be connectivity points in communities for local internet

service providers to tap into for last-mile service to

customers. Preparation work has already taken place at nearly

100 government, university and community college sites in

eastern and northern Kentucky.

“The KentuckyWired project levels the mountains and the

playing field for the people of eastern Kentucky to compete in

the global, data-driven economy,” said Dr. Devin Stephenson,

president of Big Sandy Community and Technical College. “This

is the single most important investment in economic and

workforce development that will have a profound impact on the

entire Commonwealth, from Pikeville to Paducah.”

FOA is a training partner with KY Wired project through the

Kentucky Community And Technical College system. Big Sandy is

one of the 5 schools in eastern KY already offering FOA

training and certification in support of the project. More

schools will be coming online as the project expands.

Read

the KY Wired press release here.

Pennsylvania

Turnpike Plans To Install 550 Miles Of Fiber

The

Pennsylvania Turnpike Commission plans to develop a fiber-optic

cable broadband internet network along the 550 miles of

turnpike.The network would replace the turnpike’s

microwave-radio system, whose capacity to carry data from toll

plazas, camera systems and road sensors to centralized computers

will eventually reach its limit, turnpike officials said.

Turnpike chief information officer Scott Fairholm envisions a

system that transmits traffic, road and weather conditions

directly into car and truck dashboards outfitted to accept the

information, a feature future vehicles will certainly have.

Consultants will help choose private contractors to build the

system at their own expense, operate it and sell excess network

capacity to other state agencies or private businesses. The

public-private partnership means construction and operations

won’t cost the turnpike anything and could produce some revenue

from selling excess capacity

Scranton

Times-Tribune October 17, 2016

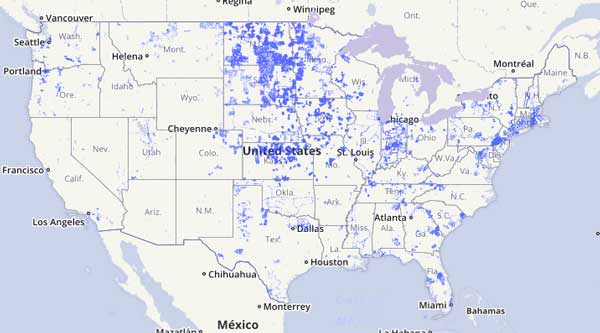

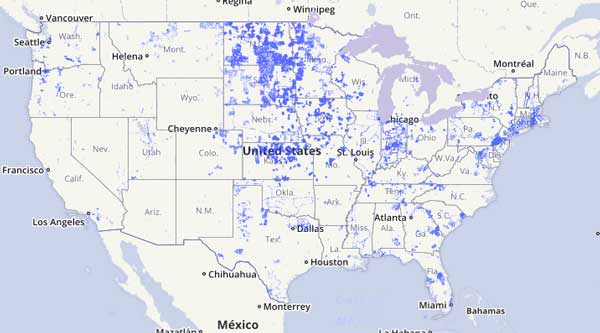

Where

Are FTTH Networks In America?

A good

place to find out is the "National

Broadband Map" maintained by NTIA,

the US National Telecommunications And Information

Administration. The map below shows the FTTH map, but you

can also see maps for DSL, cable modems and wireless. You can

also read

broadband news here.

178

Communities In America Are Building Broadband Networks

Broadband

Communities Magazine has counted 178

Communities in 38 US States And American Samoa that are at

some stage in developing or operating municipal owned

broadband networks. This article is a very good read if you

are interested in developing a muni broadband network

because it shows the numerous ways these operations can be

structured. Some are public owned, many by electrical

companies, some public/private partnerships and some started

public but have been sold to private operators. Some only

offer services to businesses, others to consumers. Some are

their own ISP, others offer a distribution network for ISPs.

The article includes a table of all the systems and the way

they are structured.

Mandatory reading if you are considering such a move.

Read

more in Broadband Communities Magazine

How Do

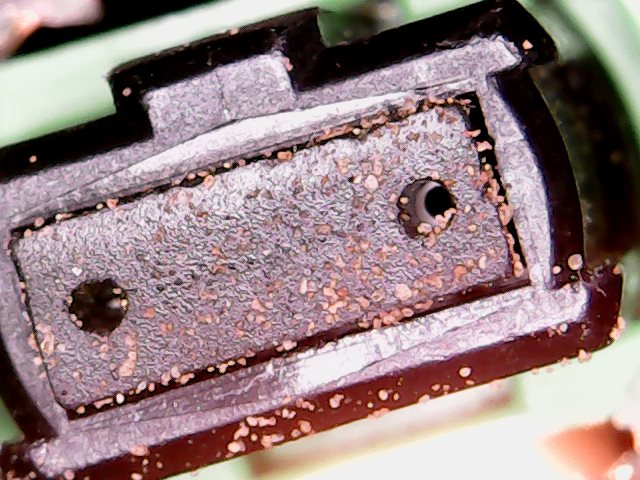

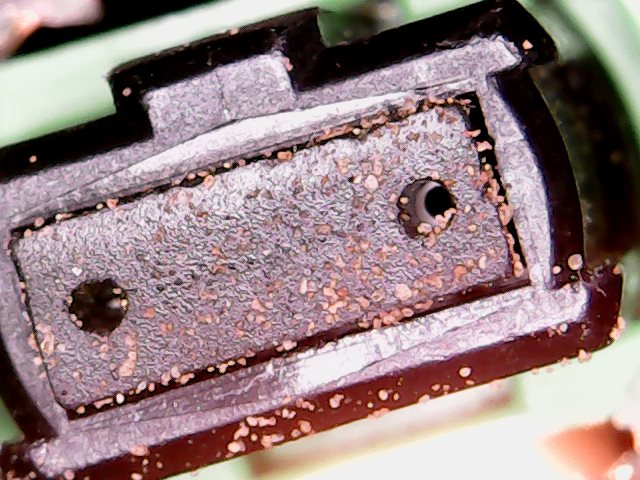

You Identify A Counterfeit Cleaver"

FOA Master

Instructor Bill Graham sent us this photo of two cleavers , one

a real Sumitomo and one counterfeit. Can you tell the

difference?

#1 is the real Sumitomo cleaver which sells for about $800 and

#2 is a counterfeit that sells for about $85.

The first thing to note is the poor quality of finish of the

metal and the roughness of the cast in logo on the top. It's

also missing the hold-down (round black plastic piece.)

In use the operation is not as smooth, especially the cutter

blade sliding to scribe the fiber.

The cleaves are not as good or consistent, not adequate for

critical work.

As they say, you get what you pay for.

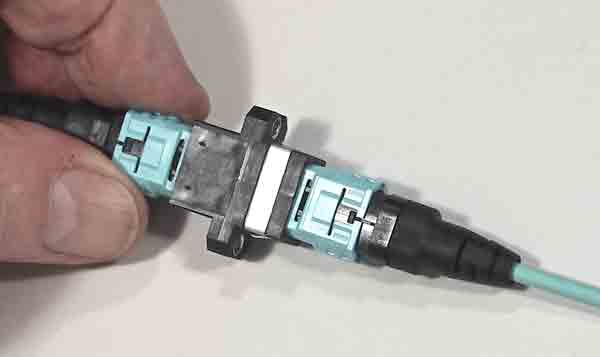

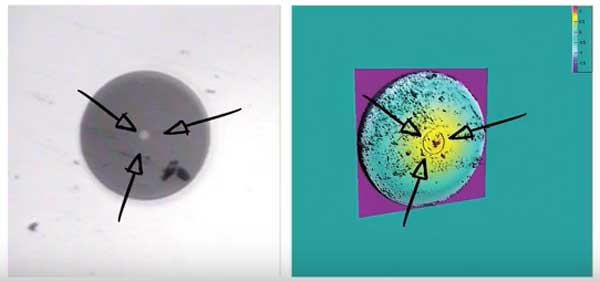

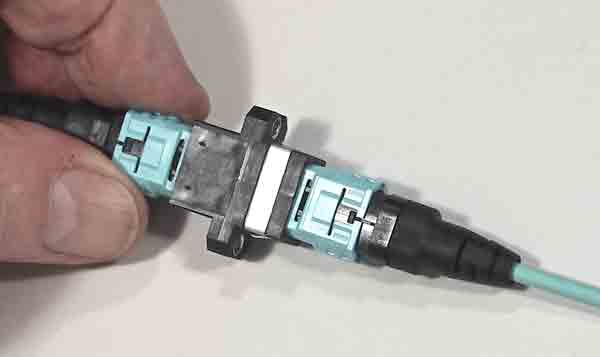

Is This

A Better Idea For MPO Connectors?

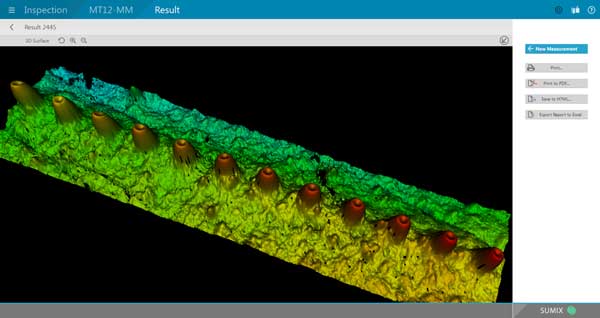

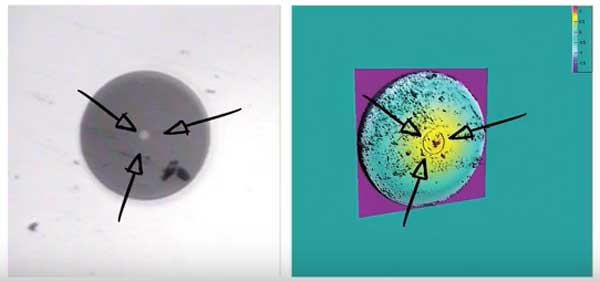

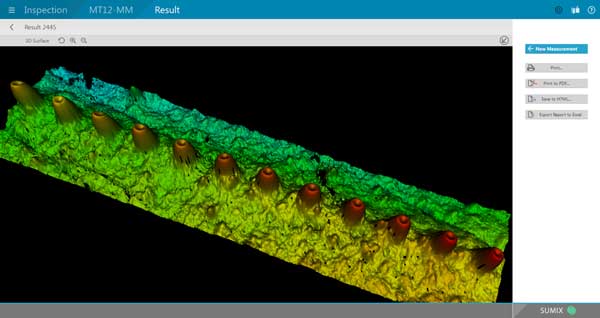

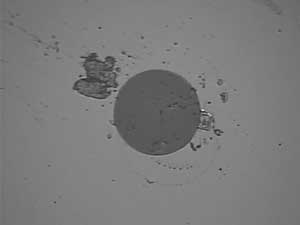

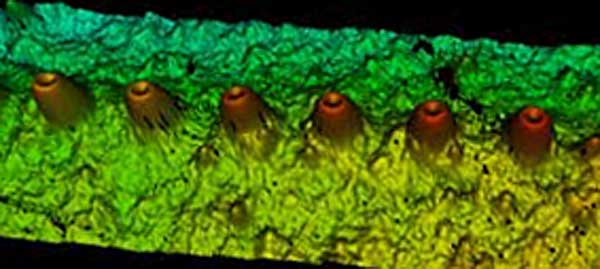

As you can

see below (next article) MPO connectors have a large area that

can get dirty. They also depend on the polishing process leaving

fibers protruding from the ferrule surface to ensure physical

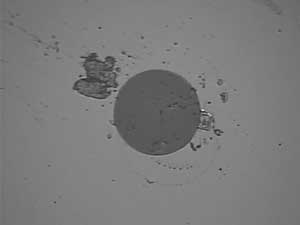

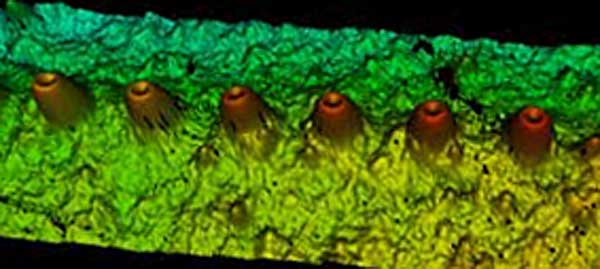

contact for low loss and reflectance. A typical MM MPO looks

like this on an interferometer:

Polishing

the connector so that all fibers protrude equally is not easy,

but is mandatory to get consistent loss on all the fibers. You

might remember an article in this newsletter that quoted a study

about the MPO claiming that the outer fibers had higher

loss. That article prompted feedback from a cable manufacturer

who said it appeared to be an artifact of the polishing process

and that another brand of polishing machine gave results where

the inner fibers had higher loss. Puzzling!

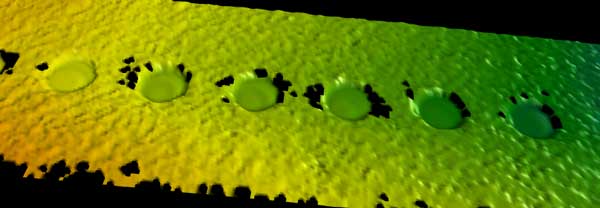

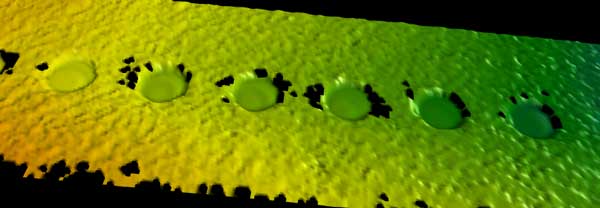

Another option is the termination process developed by Arrayed

Fiberoptics Corp. that polishes the MPO ferrule so that

the fibers are undercut slightly, then the ferrule is coated

with an anti-reflection coating like the coatings used on

photographic lenses. The Arrayed MPO looks like this:

You can see the fibers do not protrude but are just slightly

below the surface of the ferrule (just microns below). Generally

this would cause high reflectance (~ -20dB) if there were an air

gap between the fibers, but the ferrule ends are coated as you

can see in this photo:

The ferrule on the right has an antireflection (AR) coating that

reduces loss even with non-contact fibers. The manufacturer

claims that this provides more repeatable loss on the line of

fibers and reduces potential damage to the fibers. Although not

one of their claims, AR coatings are often harder than glass and

certainly the glass-filled plastic ferrule, so this should be a

much more durable MPO.

For more information, go to Arrayed

Fiberoptics Corp.

Why You

Should Inspect ALL Fiber Optic Connectors And Clean ALL of

Them

"Contamination

on the end face is 'job-1". However, while this is a

dramatic image, there can be contamination on other aspects of

the connector. My point in all of this is that cleaning

the end face is critical...but also understanding there are

potential "soil points" from other areas can/will/may save lots

of frustration. "What if dust in an alignment port

is causing misalignment of fibers

2-6-8?" Right now we are teaching to

clean the most important sectors...and that must not stop...but

teaching awareness of other aspects is the essence of "Best

Practice...to Future Proof"." Image and comment from Ed Forrest.

http://www.fiberopticprecisioncleaning.com/

Need A

Secure Network But Want Data From It - Make It "One Way"

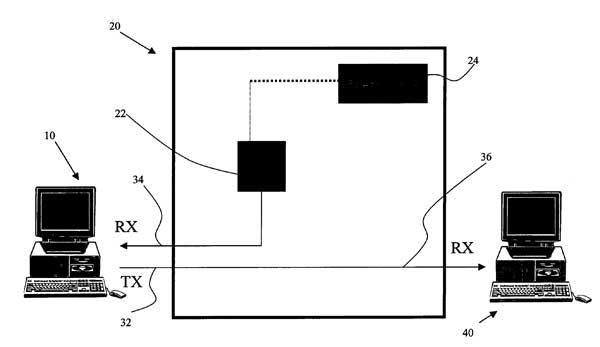

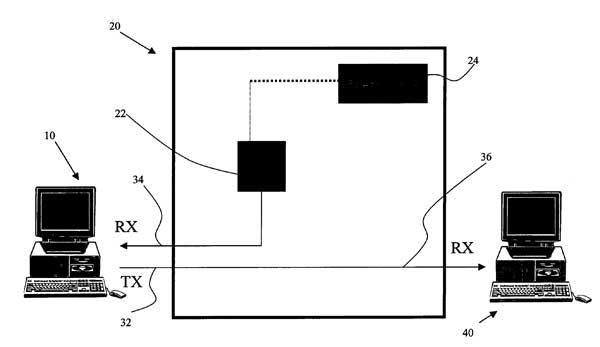

Recently an

IT person called FOA with a question. They wanted to be able to

transfer information from a remote site to a corporate network

but did not want to risk the site being compromised if the

corporate network was hacked. The solution was to make the fiber

link one way - only allowing transmission from the remote site

to the corporate network. This is not as easy as it sounds since

most fiber links are designed to be full duplex and many will

stop transmitting if there is no return signal. Plus, there

needs to be additional safeguards against data corruption.

It turns out the US Government has worked out the details and

conveniently patented it so we can find our how they did it. It's

Patent US7260833 and you can read the entire patent

application here.

This implementation uses hardware to simulate the return link

but a media converter company should be easily able to make a

one way link. Anybody know if such a thing exists?

Good

Practice Tools For OTDRs, All Free

FOA

OTDR Simulator

You

may already know that the FOA has a free OTDR Simulator you can

download from our website (go

here for directions) that allows you to practice using an

OTDR on your PC, seeing the effects of changing setup parameters

and analyzing dozens of real world traces. But here are two more

tools that can be good for practice.

OTDR

FAQs

Including

more hints from FOA Master Instructor Terry O'Malley like tests

on what the end of a fiber trace looks like with broken and

cleaved fibers.

Frequently

Asked Questions On OTDRS And Hints On Their Use

"Fiberizer"

APP Reads, Analyzes OTDR Traces

Fiberizer

is a iPhone/iPad APP that reads industry-standard ".sor" format

files and allows trace analysis on your iPhone or iPad. An

android version is in the works too. Read

more about Fiberizer. And

here are more directions on its use.

You

Should Worry About Static Electricity When Cleaning Connectors

We all know the problems with dirty connectors but keeping

connectors clean, even after just cleaning them, can be a

problem. The Microcare Sticklers people have been talking about

the problem of static electricity for some time. When you clean

a connector with a dry cleaner, you may cause a static charge on

the connector ferrule that will attract more dirt from the air.

Sticklers solution is a cleaning fluid that is conductive and

prevents static. Used with their cleaning tools, it reduces the

static problem and helps ensure clean connectors. Watch

their video here.

The

Microcare Sticklers people tell us they working on a series of

five training videos about how to clean various connectors by

application and should have the videos done by the end of

September. We'll update you on those next month.

Useful

Online Resources

We often

have contacts give us online links for useful information which

we like to share with our readers. Here are two:

Electrical/Low Voltage Workers

in Wisconsin

Casey Healey, Business Agent for IBEW Local 159 in McFarland,WI

suggested a link to the Wisconsin

Electrical Workers on the FOA jobs website. They have nine

IBEW locals that cover the entire state of Wisconsin. All nine

locals use this website in search of low voltage technicians

that are certified in copper or fiber. After an individual fills

out the employment opportunities form on the website a

representative from that person's area would be in contact with

them to discuss job opportunities within the IBEW as a low

voltage apprentice, trainee or a technician. In Wisconsin they

teach the 3 year NJATC Voice Data Video apprenticeship program.

WI JATCs use the books that FOA has written for the NJATC in

their curriculum.

Finding Legal Information

As

the two articles above illustrate, sometimes you get involved in

a situation where you need local legal information or

assistance. When you need legal information around the US, it

can be very frustrating to find the right contacts. A friend of

the FOA, Debbie Mayer, sent us this lead:

"I came across a site that has alleviated my frustrations and

has proven to be rather accurate for my own purposes. The site,

courtsystem.org

seems to have a complete database of listings for all emergency,

legal and law enforcement government offices in the country –

with working phone numbers (at least for the ones I’ve tried!).

I wanted to share the site because it has saved me a few

headaches and I’m sure it would be useful to others as well."

The word on

the "Dig Once" program is getting out - FOA is getting calls

from cities asking us for information and advice. It helps that

the current Administration is trying to convince cities of the

advantages of installing ducts or conduits when they dig up a

street so they don't have to do it again. Here are some links

for more information.

The DoT page on the administration’s Executive Order: http://www.fhwa.dot.gov/policy/otps/exeorder.cfm

From the Council of State governments: http://www.csg.org/pubs/capitolideas/enews/cs41_1.aspx

From the city of San Francisco: http://sfgov.org/dt/dig-once

An article about Dakota County, MN: https://muninetworks.org/tags/tags/dig-once

And

the one to download and hand out:

A “How To” Guide from The Global Connect Initiative: https://share.america.gov/wp-content/uploads/2016/04/6.-GCI-Dig-Once.pdf

Lennie

and Uncle

Ted's Guides Are Updated And On The FOA Website

Lennie

and Uncle

Ted's Guides have moved to the FOA website.

Lennie is the place where many if not most fiber techs

begin their education. FOA has just updated the two guides

to ensure they stay relevant - more than 20 years after

they were first written.

Lennie goes all the way back to 1993 when he was created

as the mascot of the original "Fiber U" conference - the

same Fiber U that is now the FOA's web-based training

site. Lennie

Lightwave's Guide To Fiber Optics was created as

a beginner's introduction to fiber optics. Over 60,000

printed version of Lennie's Guide were given away and it

became one of the first commercial web pages in 1994. Uncle

Ted's Guide To Communications Cabling was written

a few years later to introduce techs to "Cat 5" - UTP

wiring - that had only recently been standardized in

TIA-568.

Lennie and Ted's Guides are used in the current Fiber U

online self-study programs and are still the best place to

start learning about fiber optics.

Lennie

and Uncle

Ted's Guides are online at the links here, can be

downloaded as printable PDFs and are now also available as

free iBooks on iTunes.

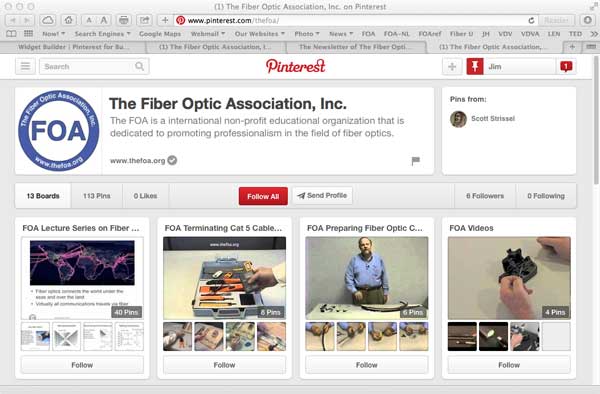

Articles

Worth Reading On

FOA has

been posting articles "Worth Reading" on our Pinterest

board instead of including them in our monthly newsletter.

If you subscribe to our board, you get notified when the

articles are posted instead of waiting until the end of the

month. Recently postings include:

Sign up at the FOA Pinterest

"Worth Reading" board

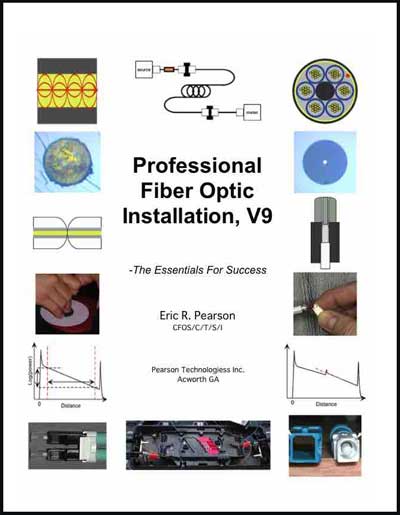

Two New

Books From FOA - Not Just For Installers - Their Bosses Need

To Read Them Too!

These

books should be on the bookshelves of network

owners or managers, facilities managers, supervisors of

the installers and anyone else involved with fiber optic

networks.

FOA has

published two new books that provide useful information for

those involved in fiber optic projects, and not just for

installers. The latest, the FOA

Reference Guide To Fiber Optic Network Design,

is a comprehensive guide to designing fiber optic networks of

any type, from concept to completion. This book looks at design

from the initial need for communications through the process of

setting the route of the cable plant, choosing components,

finding a contractor, planning the installation and documenting

the process from beginning to end.

While one might think the focus of the design book is on the

person actually designing the network, it is also aimed at those

for whom the network is being designed - the network owner or

manager, facilities manager, supervisors of the installers and

anyone else involved in the process. We especially think that

everyone who contracts for fiber optic installations should have

a copy of this book on their bookshelf as a reference for when

they are involved in a project.

The second book which we released recently, the Outside

Plant Construction Guide, is another book aimed at a

wider audience than installers. Certainly it's of interest to

installers, being the only book we know about the actual

construction process of installing fiber optic cables, but it is

also useful to the designer of the network and those who

contract for fiber optic cable plant installation, especially if

they are involved in getting permits and easements or having to

explain to others the process of installation.

Both books, like all

FOA books, are inexpensive and available in paperback or

Kindle formats.

FOA

Reference Guide To Fiber Optic Network Design And FOA's

Outside Plant Fiber Optic Construction Guide

Read

More about the FOA

Reference Guide To Fiber Optic Network Design

and

More

information on the FOA

Outside Plant Fiber Optics Construction Guide

Want To

Learn More About DIY FTTH?

Southern

Fiberworx is a DIY FTTH Project in Georgia

Southern

Fiberworx is a DIY FTTH Project in Georgia

It seems

like every week FOA gets another call from a town, real estate

developer or utility wanting to start a FTTH project for their

area. FOA has created several videos and a a web page on this

topic to help anyone get started.

FTTH

Case Studies: Do-It-Yourself FTTH

FOA has a

series of videos on do it yourself (DIY) FTTH. The first three

videos are online now:

FOA

Lecture 45 Do It Yourself FTTH (Fiber to the Home) What's

involved in building a FTTH network of your own.

FOA

Lecture 46 Do It Yourself FTTH (Southern Fiberworx)

(FOA Newsletter

November 2015) How one company, Southern Fiberworx in

Cordele, GA did it themselves.

FOA

Lecture 46 Do It Yourself FTTH (Southern Fiberworx)

(FOA Newsletter

November 2015)

Another

Source Of Articles On Fiber

FOA

President and editor of this newsletter Jim Hayes has also been

writing a column in Electrical

Contractor Magazine for more than 15 years now. Electrical

contractors do lots of fiber work and this column has covered

some toics they are interested in including installation

processes, network design, fiber applications and in the last

year, a lengthy series on dark fiber - what it is, how's its

used and how it benefits the growth of communication. A recent

web site redesign makes it easier to browse all these articles -

just go to http://www.ecmag.com/contributing-authors/jim-hayes

and you can see all of them.

Keep Up

With Google Fiber News

Google is

moving ahead in Austin and starting in the SE building Google

Fiber networks. They just announced projects in San Diego and

Irvine, CA and Louisville, KY. Here is where to keep track

of what is happening with Google Fiber - the

Google Fiber Facebook page!

Fiber

Optic Education For Students At Any Age

We hear

about fiber optics all the time - it's in the news whenever we

hear articles about high tech, the Internet and communications,

and many communities are getting "fiber to the home." But few

people really understand fiber optics or how it works. FOA is

focused on educating the workforce that installs and operates

these fiber optic networks but we're always getting inquiries

from STEM (science, technology, engineering and math) teachers

who want to introduce fiber optics to younger students in K-12

grades or technical schools.

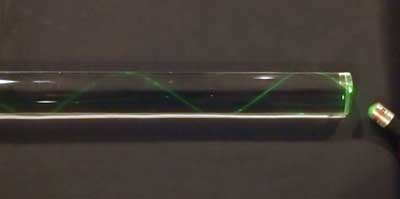

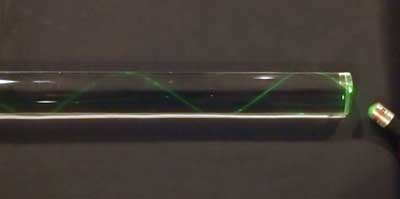

Using red laser light (a VFL here but a laser pointer works

also) to show how fiber guides light.

FOA has begun developing a series of YouTube videos intended for

teaching students in elementary, middle and high schools about

fiber optics. The first FOA video is titled "Fiber

Optics For Teachers." With this video, we show teachers

how fiber works and carries signals and then explains simple

experiments to demonstrate how fiber optics works in the

classroom using some plastic fiber and a laser pointer. Since

many teachers do not know where to get the fiber, the FOA offers

to send them a sample for use in demonstrations in their

classroom (USA only right now.)

At the end of the video, teachers are given directions on how to

request samples of the plastic fiber from the FOA.

This video joins the "Fiber Optics Live" series How

Light Travels In A Fiber, Fiber

Attenuation and Connector

Loss that show how fiber works using simple experiments

that can be duplicated in any classroom. More videos will be

coming soon.

If you have kids or know some teachers who would be interested,

please send them to the introductory video Fiber

Optics For Teachers and we'll be glad to help them

get started with some entertaining programs for their

classrooms.

Resources

For Teachers In K-12 And Technical Schools

Teachers in all grades can introduce their students to fiber

optic technology with some simple demonstrations. FOA has

created a page for STEM or STEAM (science, technology,

engineering, arts

and math) teachers with materials appropriate to their

classes. Fiber Optic

Resources For Teachers.

If

you have kids in school or know teachers who are interested,

send them to the FOA page Fiber

Optic Resources For Teachers.

Ruby

Opto Systems (India) Offers Educational Systems For Fiber

Optic Fundamentals

The present

technological advancements in STEM (science, technology,

engineering and math) education have evolved through research on

basic experimentations. Optical fibers applications are no

exceptions.

RUBY OPTO SYSTEMS in India has developed a series of educational

apparatus to help demonstrate fiber technology and help students

understand the theoretical and experimental aspects of optical

fiber technology and optical fiber sensor applications.

The design of experiments comprises of losses or attenuation due

to bending (total internal reflection),

misalignments (through beam) and sensing (reflective beam)

apart from losses due to optical fiber end preparation, optical

fiber lengths, source and detector coupling and the numerical

aperture of an optical fiber.

The optomechanical components are ergonomically designed

for the purpose of hands-on experience. The methodical procedure

of conducting the sequence of experiments substantiate towards

the understanding of basic principles and further basic

computation of power budgeting, the fundamental criteria of an

optical fiber network. The seamless integration of modules/

components based on the design of the experiment make s it

versatile and not a mere plug and play monotonous activity.

For more information, see the Ruby-Opto

website or email the developer, Parimal Kowtal at

<parimal.kowtal @ gmail.com>

Should

Your Company Become An FOA Corporate Member?

As all FOA

individual

members know, they join the FOA by becoming certified,

mostly taking their CFOTs but some CPCTs, either by

attending a FOA approved school or joining directly based on

field experience (our "work to cert" program.) Over the years,

we've been contacted by manufacturers, contractors, consultants,

and other types of organizations who ask about becoming members.

We don't certify companies or organizations, we told them, so we

were not sure what we could offer as a benefit of membership.

But then, companies asked about using our educational programs

to train employees, how they could get listed on the FOA website

as service providers or if they could get a quantity discount on

membership or certification for all the FOA members working for

them. That began to sound like a benefit for being an FOA

corporate member. And providing a list of useful suppliers to

the market could be a benefit to the industry as a whole.

So FOA has quietly been letting companies and other

organizations join the FOA to take advantage of those benefits

so we now have several hundred corporate members. We've put then

into a database and listed them on the FOA website in map

and list

form. Here's the map.

The online map

and list

can be used to find suppliers and service providers.

The map, like our map of schools, lets you find the FOA

corporate members close to you. The table form lists them

by category: Installer/Contractor, Component Manufacturer,

Installation Equip. Manufacturer, Transmission Equipment,

Services/Consulting, Distribution and Users of Fiber Optic

Networks. You can sort the tables to find members meeting your

needs, e.g. by location, certifications offered, etc. Click on

any column heading to sort that column; click twice to sort in

reverse order.

How

Does An Organization Become An FOA Corporate Member?

Simple,

just fill in the online

application form. When your application is accepted, you

will be asked to pay the membership fee - $100US first

year, $50US/year or $100US/3years to renew. You will then be

listed on the online

map

and list,

have access to exclusive FOA educational materials for your

employees and get discounts on certifications and

renewals.

EXFO

Offers Super Posters And More

EXFO offers some super posters, guides and books. The FTTx and

OTDR posters are really useful! Look

at the whole selection here

MPO

Connectors

There are numerous polarity options for MPO connectors and

adding the options for breakouts on each end, you can see how

it's easy to fill 23 pages of the TIA-568 standard with

diagrams. We've tried to simplify it on an expanded

MPO page on the FOA Guide which we recommend you read.

There is a new YouTube video on this part of the MPO polarity

also.

New

FOA YouTube Videos - Focus On MPO Connectors - Prefab Cabling

With MPOs, Testing MPOs and MPO Polarity

We continue

to get inquiries about MPO connectors, especially testing them.

A continual concern is the variability of loss when testing

them. It seems they are not all that repeatable, making testing

confusing. We've tried to create materials that explain them and

their use. We've

recently added three more videos - all focused on the MPO array

connector - to the FOA

YouTube channel.

The Panduit PanMPO Connector

FOA

Lecture 41 Prefabricated (Preterminated) Fiber Optic Cabling

Systems

FOA

Lecture 42 MPO (Multifiber, Array) Connectors and How To

Test Them

FOA

Lecture 43 Managing Polarity of MPO Connectors (using the

PanMPO Connector)

FOA

Lecture 44 MPO Connector Fiber Polarity

Safety

On The Job

Safety is

the most important part of any job. Installers need to

understand the safety issues to be safe. An excellent guide to

analyzing job hazards is from OSHA, the US Occupational Safety

and Health Administration. Here

is a link to their guide for job hazard analysis.

FOA also has lots of information on safety: FOA

Guide, YouTube

video and a Safety

Poster

"Worth

Reading" Is Now On

Join

FOA on Pinterest.

We have been posting links to pages "Worth

Reading" on a special FOA Pinterest page. You can join and

keep up to date with the news on our industry which we put

there.

Recent

posts cover utilities using new generation telecom, India's

plan for 100 smart cities, Cincinnati Bell bets on fiber,

various opinions on the US battle over net neutrality, etc.

Good

Practice Tools For OTDRs, All Free

FOA

OTDR Simulator

You

may already know that the FOA has a free OTDR Simulator you can

download from our website (go

here for directions) that allows you to practice using an

OTDR on your PC, seeing the effects of changing setup parameters

and analyzing dozens of real world traces. But here are two more

tools that can be good for practice.

OTDR

FAQs

Including

more hints from FOA Master Instructor Terry O'Malley like tests

on what the end of a fiber trace looks like with broken and

cleaved fibers.

Frequently

Asked Questions On OTDRS And Hints On Their Use

"Fiberizer"

APP Reads, Analyzes OTDR Traces

Fiberizer

is a iPhone/iPad APP that reads industry-standard ".sor" format

files and allows trace analysis on your iPhone or iPad. An

android version is in the works too. Read

more about Fiberizer. And

here are more directions on its use.

Events of

Interest

Don't

Miss These Seminars and Webinars:

TIA

FOTC offers regular webinars and archives

them here so you can watch anytime.

Installation

and Management of Customer-Owned Outside Plant Cabling

by Hubbell and Clearfield

The

specification, design, installation and management of

customer-owned outside plant cabling systems require

knowledge, tools and systems that often differ from those used

for in-building communication systems. The physical conditions

are less benign, which affects everything from installation

techniques to the equipment that houses and protects the

cabling. This web seminar hosted by Cabling Installation &

Maintenance addresses several aspects of customer-owned

outside plant cabling administration, emphasizing the

capabilities and physical requirements of products and systems

deployed in these environments.

Watch

anytime - sign up here.

Fiber

Testing - Presented By Jim Hayes, FOA

This

webcast seminar, presented by Jim Hayes, examines several ways

in which fiber testing- both insertion loss and OTDR testing -

has evolved. The seminar will begin with a basic tutorial of

fiber-transmission principles and test fundamentals. It will

then discuss the uncertainties of each fiber-optic measurement

method. The seminar will then address some of the developments

that have served to improve the certainty of test results, as

well as how technicians can use their instruments more

effectively to reduce measurement errors.

Watch

Anytime - Sign Up Here

~~~~~~~~~~~~~~~~~~~

New

local programs for fiber installation training New

local programs for fiber installation training

See

the Light® Fiber Optic Training Program

Webinars, seminars and certification training classes.

Corning offers a library of

more than 200 videos that help our customers with

everything from product preparation and installation to proper

testing procedures. Our free Video Library Tool provides direct

links to individual Corning videos, and allows you to filter by

topic or area of interest. Register

to download the Video Library Tool.

~~~~~~~~~~~~~~~~~~

RETURN

TO INDEX

What's

Happening @ FOA What's

Happening @ FOA

FOA

has three LinkedIn Groups

FOA

- covers FOA, technology and jobs in the fiber optic marketplace

FOA

Fiber Optic Training - open to all, covers fiber optic

technology and training topics

Grupo

de La Asociación de Fibra Óptica FOA (Español)

FOA

Standards:

FOA now offers free standards for datalinks and testing the

installed fiber optic cable plant, patchcords and cable, optical

power from transmitters or at receivers and OTDR testing.

What

Is A Fiber Optic Cable Plant?

In a recent

standards meeting, that issue was discussed with some

disagreement as to what constituted a "cable plant." It seemed

to be a perfect topic for another FOA "1Page Standard," so a

draft version is now uploaded for review (FOA

Standard FOA-6, Fiber Optic Cable Plant). Feel free to

review it and comment to the FOA at info@thefoa.org.

Available

also is a new standard for Datalinks.

Look for the "1

PageStandard" web page and in the FOA Online Reference

Guide.

Go to the

FOA "1

Page Standards"

NECA/FOA

301 Fiber Optic Installation Standard

Standards

cover components and systems and how to test them, but rarely

get into installation issues. The FOA NECA 301 standard which

covers installation of optical fiber systems has been revised

for the second time, adding considerable new materials. This

standard is derived from FOA educational material put in

standards form and approved by ANSI as an American National

Standard. It's specifically written to be used in contracts to

define "installation in a neat and workmanlike manner." The

standard is available from NECA.

FOA members can go

here for instructions on how to download your free copy.

Application

of Standard Project Management Processes in Fiber Optic Cable

Plant Project Management

By

Alfred

Sankara, PMP, CFOS/D – Telecommunications Project Manager

Organizations in the communication industry are proving that

adopting proven project management practices reduces risks, cuts

costs, and improves success rates of projects. The present

article demonstrates how standard project management processes

apply to fiber optic cable plant project management.

The article compares the Project Management Institute (PMI)’s

standards and guidelines to the FOA’s best practices in terms of

fiber optic cable plant project management. PMI is the

world's leading not-for-profit professional association for the

project, program, and portfolio management profession. PMI

strives to mature the profession of project management through

standards, certifications, resources, tools, academic research,

publications, professional development courses, and networking

opportunities.

The PMI’s Guide to the Project Management Body of Knowledge

(PMBOK ® Guide) defines the project lifecycle as a combination

of the following three (3) main phases: Project Initiation,

Project Execution, and Project Closing. This article shows that

the FOA’s fiber optic cable plant project management lifecycle

phases, which include the Design, Installation, and Testing, fit

with PMI’s recommended project lifecycle.

Alfred

Sankara is a

telecommunications specialist who has been active in the

planning, deployment, and operations of telecommunications

infrastructure since 1999.In the United States and Africa,

Alfred has been involved in the execution of various

telecommunications projects, including plans and

specifications development, fiber optic network deployment

(FTTH, SONET, DWDM, Carrier Ethernet, and OTN) and wireless

network implementation (WiMAX, Wi-Fi, UMTS, and LTE).Alfred

co-founded DigiBridge TelCo to contribute to reduce the

digital divide in emerging countries by assisting

governmental entities to deploy state-of-the-art

telecommunications infrastructure.

Download

a copy of Alfred's article on project management for fiber

optic construction.

RETURN

TO INDEX

Free

Fiber U Self-Study Programs

FOA's

"Fiber U" free online self-study programs help you learn about

fiber optics, study for FOA certifications or use them to help

create "blended learning" classes. There are two new free online

self-study programs on Fiber

U. Fiber Optic Network Design is for those interested in

learning more about how to design fiber optic networks or

studying for the CFOS/D certification. FTTx is for those wanting

to know more about fiber to the "x" - curb, home, wireless, etc.

- or studying for the CFOS/H certification.

Got to Fiber U

for more information.

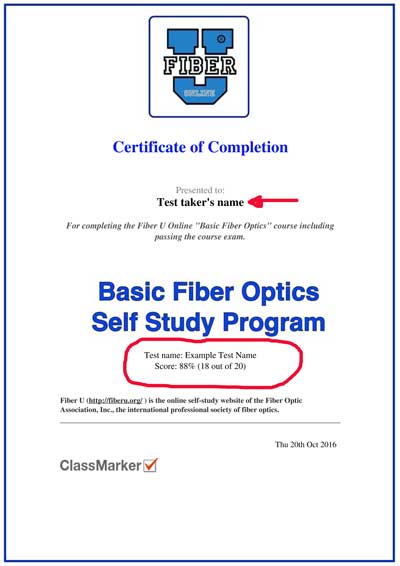

Fiber U

Online Self-Study Programs Offer Option Of Certificate of

Completion

FOA has

been offering quite a few free online self-study programs on Fiber

U, our online learning site. We are always getting

questions about getting a certificate for completing the course

online, so we have setup an option to take a test online and get

a certificate of completion for these online courses.

While it's not FOA certification, FOA will recognize a Fiber

U Certificate of Completion as background experience to

qualify for applying for FOA certifications. We also intend to

expand the program to more specialized topics as preparation

for FOA specialist certifications.

If you have associates that want to get started in fiber,

have them take this course online to get started. Go to Fiber

U and get started.

Lennie

& Uncle Ted Now Available As Free Books on iTunes

Lennie

Lightwave's Guide to Fiber Optics and

Uncle

Ted's Guide To Communications Cabling

are now available free to iPad users who can download them from

the Apple iTunes store. Of course they are still available

online or for download.

Lennie's

Guide has always been the world's favorite introduction to fiber

optics. It was first published in the mid-1990s by Fotec, the

fiber optic test equipment company famous for its "Fiber U"

training conferences and more than 60,000 printed copies were

distributed. Lennie was one of the earliest commercial webpages

and is still online today (and as popular as ever) at http://lennielightwave.com.

Uncle Ted's Guide was

created at the request of Lennie readers who wanted a similar

simple introduction to "Cat 5" wiring. This latest version of

Uncle Ted's Guide covers the all premises cabling topics -

wiring, fiber and wireless.

You can find these free guides on Apple's iTunes Store or on the

FOA website - go here for all the links: Lennie

Lightwave's Guide to Fiber Optics and Uncle

Ted's Guide To Communications Cabling

FOA

Textbook Now Available in French / FOA manuel disponible

en français

Available

from Amazon.com / Disponible

sur Amazon.com

And

from Createspace / Et

à partir de Createspace

FOA Now

Offers Fiber Optic Textbook In Spanish

Guía de

Referencia de la Asociación de Fibra Óptica (FOA) Sobre Fibra

Óptica

- Reference

Books for FOA Certifications available on Kindle and

iPad/iPhone as well as printed

We have created three new FOA books to be used in training for

FOA certifications and as reference books for contractors,

installers and end users of fiber optics. These books have

full curriculum support, including free curriculum materials

for teaching FOA certification courses. Because we are

self-publishing these books using more modern "publish on

demand" technology, they are easier to keep up to date, easier

to buy and much, MUCH cheaper!

All

are now available in print and electronically in Kindle and

Apple iBook versions. The basic fiber optic book is also

available as a self-study program in an Apple APP for

iPad/iPhone/iPod.

Details on the new book each of the new books are at the book

pages linked to the photos above.

RETURN

TO INDEX

FOA

iPad Apps

FOA

LossCalc

FOA

LossCalc estimates the optical loss of a fiber optic link. This

will save time for the installer of a fiber optic link needing

to know whether test results are reasonable and/or make a

"pass/fail" determination. It can also help the designer of a

link to determine if communications equipment will operate over

this link. FOA

LossCalc estimates the optical loss of a fiber optic link. This

will save time for the installer of a fiber optic link needing

to know whether test results are reasonable and/or make a

"pass/fail" determination. It can also help the designer of a

link to determine if communications equipment will operate over

this link.

By choosing the type of link (singlemode or multimode) and

specifying the length of the fiber and numbers of connections

and splices, it will calculate the end to end loss of the link.

The app has default specifications for singlemode and multimode

links or the user may create custom setups with specifications

appropriate for any application. http://itunes.apple.com/us/app/foa-losscalc/id476262894?mt=8&ls=1

Self -Study in Fiber Optics

Our

first app is a self-study version of the FOA Reference Guide to

Fiber Optics. The FOA APP builds on the FOA basic fiber optic

textbook to create an interactive learning environment that

builds on the iBook electronic version of the book to add a

guide to use for self-study and real-time testing that provides

feedback on what you have learned and correct answers to

questions answered incorrectly. Our

first app is a self-study version of the FOA Reference Guide to

Fiber Optics. The FOA APP builds on the FOA basic fiber optic

textbook to create an interactive learning environment that

builds on the iBook electronic version of the book to add a

guide to use for self-study and real-time testing that provides

feedback on what you have learned and correct answers to

questions answered incorrectly.

The FOA APP is priced at only $9.99, same as the iBook, so the

self-study program is free. Download it from the Apple APP Store

with your iPad or iTunes.

http://itunes.apple.com/us/app/foa-guide/id434354283?mt=8&ign-mpt=uo%3D4

RETURN

TO INDEX

The

FOA has many videos on  ,

including two Lecture Series (Fiber Optics and Premises

Cabling), Hands-On lectures on both and some other informational

and instructional videos. For all the videos, go

to the FOA Channel "thefoainc" or use the direct links

below. ,

including two Lecture Series (Fiber Optics and Premises

Cabling), Hands-On lectures on both and some other informational

and instructional videos. For all the videos, go

to the FOA Channel "thefoainc" or use the direct links

below.

View

a complete list of FOA Videos with links to each video on

YouTube.

For End Users - Who Think Fiber

Needs Maintenance

FOA

Lecture 39 Maintaining Fiber Optic Networks

FOA Product Demonstrations

In the June FOA Newsletter, we talked about the new 3M

"disposable" cleaver, the Easy Cleaver, which is provided free

with 3M connectors and mechanical splices that need cleavers. We

got samples of the Easy Cleaver from 3M and tested them

ourselves, and they work great. You can see for yourself how

they work in this FOA

YouTube Video about the Easy Cleaver.

We also tested the new Ripley/Miller FO-CF Center Feed Fiber

Stripper and used it as an opportunity to show the other three

common types of strippers, the Miller, MicroStrip and NoNik and

how they are used. So you get a review of how to strip fiber and

a product review of the new stripper in this FOA

YouTube video about fiber strippers.

New FOA Lectures - Jargon and

Jobs

How to

Talk Fiber Optics - an introduction to fiber optic jargon

- the perfect place to start learning about fiber optics.

Where Are

The Jobs In Fiber Optics? FOA talks about all the

applications for fiber optics, what jobs involve and the

qualifications for the workers in the field.

What's A "Network"

That's a common question from fiber and cabling people. Even

though they may be installing the cable plants for networks,

often the nature of networks is not something they have been

exposed to, other than perhaps the catch-all "star network"

description. But what is a network? What does it connect? How

does it connect users and how does it allocate the bandwidth to

them? How do various network types vary?

We've been working on some new YouTube videos on networks,

starting as we usually do on a new subject with the basics. We

have these three videos online now, but watch for more.

Fiber

Optics - Live! A

series of videos that use lab demonstrations to show how

optical fiber works.

Prepolished/Splice

Connector Termination (Panduit OptiCam)

Cabling

Project Management - what's involved in a

copper/fiber/wireless project -advice for the customer and the

contractor

Hazards

Of Counterfeit Cable

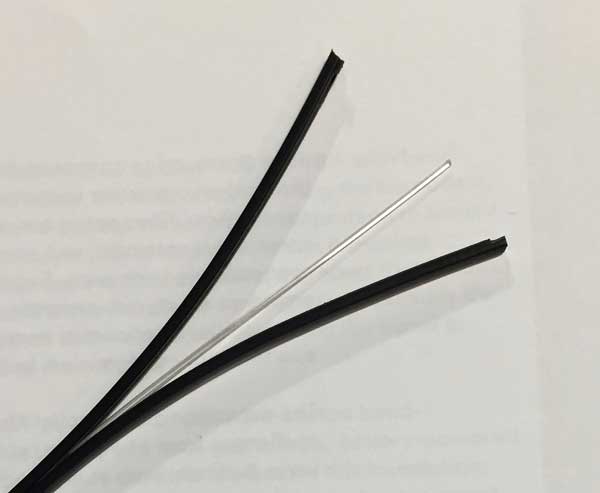

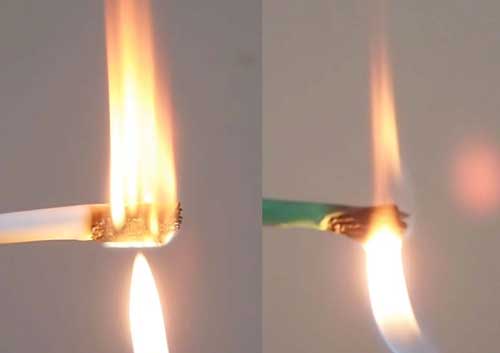

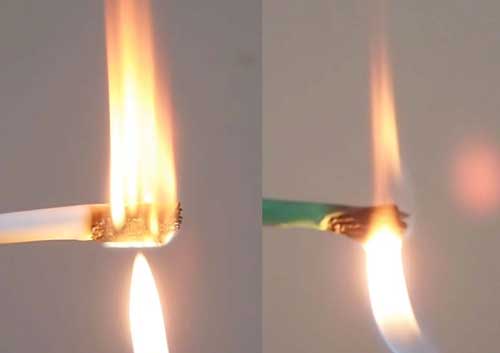

You may

have read the stories we have written about the counterfeit

"Cat 5" cable made from copper-clad aluminum rather than pure

copper. Recently we tried an unscientific burn test on the

cable compared to a known good UL tested cable and posted a

video on YouTube. You can see the results below.

Counterfeit

Cable Real UL-rated cable

The

difference is obvious and the danger is real. Watch the video

on YouTube: Premises

Cabling Lecture 11: Counterfeit Cat 5 Cabling

View a

complete list of FOA Videos with links to each video on

YouTube.

View

all the FOA Channel on YouTube.

RETURN

TO INDEX

What's

New in the FOA Online Fiber Optic Reference Guide?

We are

continually updating the Online Reference Guide to keep up with

changes in the industry and adding lots of new pages of

technical information. Go to the FOA

Guide Table of Contents to see the latest updates - look

for  . .

FOA

Guide page on Metrology-

the accuracy of measurements

Fiber

For Wireless: FTTA

and DAS

Updated page on Data

Centers

Le

Guide de référence pour la fibre optique de la FOA est

maintenant disponible en français.

Updates

for new FOA certifications in FTTA

and Data

Centers

What do you do when you need to test fiber or

cable on a reel? Here is a new page on Bare

Fiber Testing

Couplers or splitters are used in FTTH and OLANs. How

do you Test Splitters?

Tapping fiber has been a big topic in the news. How

do you tap fiber?

The page on Optical

LANs (OLANs) has been expanded with new material and

links.

What's

A Network? A simple explanation of network types and

operation has been added to the FOA Online Guide.

We

have updated the

"Datalinks"

page.

Three

"Quickstart Guides" for fiber optic testing: cable

plant & patchcord loss, power

and OTDR

Learn

More About OTDRs - Download a Free OTDR Simulator

More and more installers are being asked for OTDR testing but

using these instruments is not easy. They are hard to set up

properly and complicated to interpret the traces. Using the

autotest function can lead to disastrous results! The FOA has a

good tutorial on OTDRs on our Online Reference Guide and we

added a free download of an OTDR

simulator to the OTDR

section so you can learn how to use an OTDR on your PC.

More

New Info:

Links

to manufacturers

and distributors of fiber optic lighting products.

The

FOA Online Fiber Optic Reference Guide has become very

popular - perhaps the most popular technical website ever,

typically with over 360,000 users downloading about 1.75 million

pages in 2011! We continue updating materials regularly, keeping

it as up to date as possible.

Find

What You Want Using "Google Custom Search

There's

so much information on the FOA Tech Topics and Online Fiber

Optic Reference Guide that even a well-organized Table of

Contents isn't enough and when the material is always changing,

an index is impossible to maintain. So the FOA is using the

latest technology in search, Google Custom Search, which will

allow you to search just the FOA Tech Topics and

Online Fiber Optic Reference Guide for any topic you want to

find more about. Try

it! There's

so much information on the FOA Tech Topics and Online Fiber

Optic Reference Guide that even a well-organized Table of

Contents isn't enough and when the material is always changing,

an index is impossible to maintain. So the FOA is using the

latest technology in search, Google Custom Search, which will

allow you to search just the FOA Tech Topics and

Online Fiber Optic Reference Guide for any topic you want to

find more about. Try

it!

Go

to The

FOA Online Fiber Optic Reference Guide.

RETURN

TO INDEX

New

Schools

The FOA welcomes the newest additions to our listing of FOA-Approved

Training Organizations:

Owensboro

Community and Technical College, Owensboro, KY, USA. School

# 358

Ashalnd Community & Technical College, Ashland, KY, School

# 359

Find

a listing of all the FOA-Approved schools here.

Find

An FOA-Approved Training Organization

Most

inquiries we get regarding finding a FOA-Approved training

organization want to know two things: what school is closest to

me or what school offers the certifications I need. The FOA has

about 200 training organizations we have approved worldwide so

finding the right one can be difficult! We've been looking at

ways to make it easier, and we think we've got a good solution.

In fact we have two solutions.

First we have added a sortable

table of all the FOA-Approved schools.

You can also use our FOA

Google Map to find FOA-Approved schools.

What

Should A Fiber Optics or Cabling Tech Know and What Skills Do

They Need?

FOA

certifications are based on our KSAs - the Knowledge, Skills and

Abilities that techs need to succeed. Read the FOA KSAs

for fiber and cabling techs.

School News

Feedback

We always

enjoy feedback, especially when it shows how great some FOA

instructors are. These came from students of Tom Rauch, an

instructor at BDI

Datalynk:

"I took your fiber optics certification courses this past March.

I just wanted to let you know that in two weeks I start working

as a fiber optic technician with ___ up in ___. You mentioned on

the first day of the course that there is always one guy in

class who had rubbed his last two nickels together to be there

and, in that instance, I was that guy. Now I'm going to be able

to provide for my family like never before and I owe it to the

certification that I received from you and BDI Datalynk. I just

wanted to thank you again."

"Thanks to our tremendously knowledgeable and patient instructor

Thomas Rauch, who was not only generous in sharing his wealth of

information, but he did so with ease, humor and in a way that

invited curiosity and participation. He was encouraging and

proud of our accomplishments and helped us learn from our

mistakes in a way that did not break our confidence, rather it

pushed us to better results the next go around. The hands on

labs were just AWESOME!" Just thought you should know what a

class act you have representing you in his travels..... but then

again you probably already knew that! : )

In almost 19 years at Verizon and having held numerous

positions, I have gone through many training sessions. I cannot

remember ever having been actually looking forward to coming

back to class quickly after lunch, to get back to the hands on

activities, and walking away with the sense of empowerment that

the information presented was not only relevant but dead on

point accurate! I will be signing up for the Outside Plant class

on March! I can't say enough good things about Tom and his

impact! Feel free to quote me, I can only imagine that he will

open so many doors and change so many lives in the years to

come, with his style of teaching! Great experience, awesome job!"

IBEW

and FOA Partner on Fiber Optic Training

The

International Brotherhood of Electrical Workers (IBEW) and the

National Electrical Contractors Association(NECA) through the

National Joint Apprenticeship and Training Committee

(NJATC) in

a partnership with the FOA has published a new textbook for

training IBEW apprentices and journeymen in fiber optics. The

new textbook uses the material from the FOA Reference Guide To

Fiber Optics with new material and photos from other NJATC

training partners.

FOA is pleased to have been able to assist the NJATC in the

development of this new text. FOA has been a NJATC training

partner for many years, including offering instructor training

at more than 16 of the NJATC's summer National Training

Institutes. A majority of IBEW NECA contractors do fiber optics

and low voltage, especially for applications that combine

electrical and communications cabling like smart grid,

alternative energy, traffic controls, data centers, etc.

Quote

from one of our certified instructors: I want to thank

you and your organization for all the resources you provide for

the students and the opportunity to offer the certification to

the students. The fact that you published the book yourself to

get the cost down and the unlimited free resources on your

website shows a commitment to the public that is second to none.

I let it be known to the students that the FOA is the best in

the industry at supplying knowledge and resources related to the

communication industry. I look forward to passing on the

information that you provide for the industry.

Great

Video About An FOA School And Their Training

BDI

Datalynk trains at the Unversity of Central Florida. UCF

created this incredible video on the BDI Datalynk program.

It shows the power of what they

offer on campuses around the US.

Watch the video here: http://www.ce.ucf.edu/Program/2583/Fiber-Optics-Network-Certification-Courses-Non-credit/

For more information, contact Bob Ballard, CFOS/I, BDI DataLynk,

LLC, A Vietnam Veteran-Owned Company

www.bdidatalynk.com,

Ph: 512-785-9024

RETURN

TO INDEX

Good

Question! Tech Questions/Comments Worth Repeating

Real

Questions From FOA Newsletter Readers

MPO

Connector Loss

Q: Is there a current standard, for maximum allowable

loss, for MPO fiber connectors? If so… what is the standard #

from EIA/TIA? (Was it amended in 568B, since they were

introduced?) Would it be similar to standard connectors @ 0.75dB

Max allowable loss?

A: The MPO is covered

under the TIA 568 standard. All fiber optic connectors are the

same - 0.75dB.

There are discussions being held at TIA and ISO/IEC on using a

different method of specification, statistical in nature, that

says X% would be less than YdB in several stages from 0.1-0.2 to

over 1dB, but it’s led to some headed discussions.

MPOs for MM are probably no less than 0.5dB and SM are near the

0.75dB mark. At least the SM ones are APC (usual 8 degrees, but

still a flat polish).

I’ve recently learned that MPOs are polished for fiber

protrusion to try to get fiber contact, but the evenness along

the line of fibers is harder to control.

image from SUMIX

showing protruding fibers in MPO connector

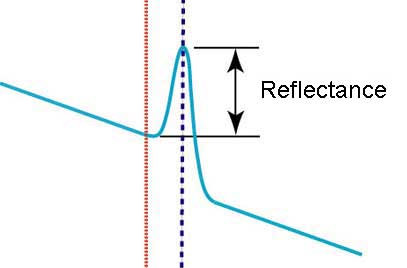

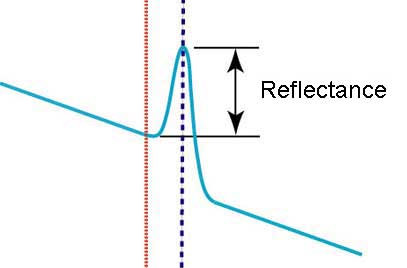

Reflectance

and OTDR Measurements

FOA

often gets questions from the field that are complicated

technical issues compounded by misunderstandings of product

performance and testing limitations. Here is an example from

recent conversations about a real world problem.

Here's

The Question:

In a project, the customer is requiring a contractor to test

connector reflectance and requiring -55dB for each

connection. They are using fusion spliced pigtails with

UPC factory connectors. They are measuring with an OTDR,

but they can’t seem to meet the -55dB reflectance requirement on

the connectors. They are getting (-51dB – (-54dB) on a

consistent bases and continually cleaning and inspecting.

I told them going into this that on the lengths of fiber they

are measuring they will have a hard time getting individual

reflectance measurements to meet the -55dB value unless they use

angled polished connectors. The lengths are 2,000’ –

9,000’+ and the way OTDRs measure reflectance will make it hard

to get that precise.

I am having them take the OTDR out of “auto” mode and shorten

the pulse width and increase the averaging time to try and get a

little more accurate measurement, but still not sure that is

going to fix the problem.

Any suggestions?

Background: How an OTDR

Measures Reflectance

Answer:

In this case, we’re looking at UPC connectors. They are

generally specified as ~ -45 to -50dB reflectance, and that can

be +/-5dB because the reflectance can’t be measured that

accurately, especially at that level.

A reflectance of -55dB means that a few parts per million of the

incident light is being reflected. To make the measurement, you

have to measure that reflected light against the backscatter

level. Both are low level, in this case -55dB reflectance level

and ~ -75 to -77dB backscatter level. The OTDR is basically

trying to measure a few PPM compared to a signal 100 times

smaller!

If you reduce the pulse width the amount of power in both

decreases significantly making the signal/noise ration worse.

With signals this small, you are working near the noise level of

the instrument and no amount of averaging can improve the

signal/noise ratio enough to get an accurate measurement. I’ve

never done actual tests with an OTDR myself to get statistics,

but I’d bet the measurement has an uncertainty of much more than

+/-5dB.

Furthermore, you must be cautious with selection of pulse width.

In a Corning

document on reflectance, they say the amplitude of a

reflective feature on an OTDR trace appears larger when measured

by shorter pulse widths and therefore are often misinterpreted

as a cause for concern during cabling or installation

measurements.

If the customer really wants or needs -55dB, they really

need to use APC connectors where the angle polish all but

eliminates reflectance. That’s what we’re seeing in most short

SM applications today (FTTH, pas

How Long Does It Take To

Transfer Data Over Fiber?

Q: Have there been any studies that show how long it

takes for data to travel over a fiber cable where the point of

origin is 500 miles away vs. a point of origin that is 5000

miles away?

A: There are several

parts to the answer, including travel time in the fiber, the

length of the data packet and processing time in the

transceiver:

1. Distance = velocity X time

Light in a glass fiber travels at the speed of light

(c=299 792 458 meters/s) divided by the index of

refraction of the glass (1.4677 @ 1310nm, 1.4682 @ 1550nm). For

long distances, 1550nm is used, so the speed of light in the

fiber is about 204,190,476 m/s - “about” because of some

secondary factors, so let’s say 204,000 km/s.

That’s about 4.9 ns/km or 4.90 ms/1000km from point A to point

B.

2. Then the speed will depend on the data speed of the network.

Obviously a system at 1Gb/s will take ~10 times longer to

transmit a packet of data than a system at 10Gb/s and ~100 times

longer than a 100G system. This speed also depends on the

protocol of transmission which determines the overhead of

transmission. Thus a 1000 byte packet has 8,000 bits and will

equal about 10,000 bits with overhead.

To transmit a 1MB file, it requires 1000 packets and

will take ~10Mbits of data, equalling 10milliseconds at

1Gb/s, 1millisecond at 10Gb/s, and 0.01 ms (10microsec) at

100Gb/s.

3. Processing time in transceivers and multiplexers. Data is

usually processed in parallel but transmitted in serial. The

conversion takes some time. Some transceivers also do some pulse

shaping which may take time. Then there are transit times to get

parallel data transmitted throught amps, lasers, (then the fiber

link) to a detector and amps and demultiplexers on the other

side.

This is hard to predict times, but it’s ~nanosecs to microsecs.

Lets say 1microsecond

For your comparison of 500miles vs 5000miles, for convenience,

lets say 1000 and

10,000km, in transmitting our 1MB file

at 1Gb/s

1000km - 4.9ms on the fiber + 10ms + 1microsec = 14.9ms

10,000km - 49ms + 10ms + 1us = 59ms

at 10Gb/s

1000km - 4.9ms on the fiber + 1ms + 1microsec = 5.9ms

10,000km - 49ms + 1ms + 1us = 50ms

at 100Gb/s

1000km - 4.9ms on the fiber + 10microsec + 1microsec =

4.91ms

10,000km - 49ms + 1microsec + 1us = 50.002ms

More Than “Single” Mode?

Q: We're now using SM fibre so it looks like we don't

need mandrels in the Ref Lead at the Light Source. The

info I have is that we need to make a couple of air coils 35mm

to 50mm in diameter. Why?

A: When you launch from

a pigtial laser source through a connector into a reference

cable, you do have several modes being propogated. It usually

takes 100m or so for the second or third order modes to

attenuate. So the coil causes them to be attenuated by the

stress enough to no longer be significant - it’s a mode filter

just like MM. If you do not do this, you will measure higher

loss in the fiber and at connections near the source. Since most

SM has traditionally been long distance, the effect was small or

ignorable, but with short links, it can be significant.

Followup Q: But how do we explain multiple modes in Single Mode

fibre?

A: When you get the core of the fiber down to ~5-6 times the

wavelength of the light, it no longer acts like geometric optics

(like MM fiber). Some of the light can travel outside the core

(see the note on “waveguide

dispersion”here http://www.thefoa.org/tech/ref/testing/test/CD_PMD.html).

At launch, significant amounts of power are at higher angles

creating short lived modes that are highly attenuated.

Replacing OM1 MM Fiber

Q: We are an automation system integrator in South

Africa. We have a client that has multimode 62.5/125 fibre optic

plant wide. None of the runs between components are longer than

2km. We intend to upgrade the technology from a proprietary

communication protocol to a standard ethernet protocol at 100

MHZ. The fibre to copper convertors we will be using are using

1300nm light source and have a Fibre Optic Link Budget of 12.8dB

for 62.5/125 um and 9.8dB for 50/125 um. The

client has been advised to replace the multimode 62.5/125 with

multimode 50/125 cabling and we need to know if this is really a

requirement.

A: Do you know how old

the fiber is? It should be what we called FDDI grade 62.5/125

fiber with a loss of ~1dB/km and a bandwidth of 500MHz-km

at 1300nm. A 2km link should have a loss of 2dB for the fiber

and ~0.5dB/connection - well under the power budget of the link.

100Mb/s Ethernet variants were designed for 2km or more on this

fiber. There is no reason to upgrade at this time, 50/125 fiber

would not be needed until Gigabit Ethernet was desired.

Bi-Directional OTDR Testing

Q: Should the testing be done with the same piece

of equipment from both ends then merge the results or does that

not matter - can you use traces from two OTDRs as long as the

test equipment is compatible and settings are adjusted properly.

A: Yes, you should use

the same test set from each end but this way - take a trace,

disconnect the OTDR from the launch cable and go to the far end

of the receive cable and connect it there to take the second

trace. The usual way people do bi-directional tests is to

disconnect the launch cable and take it to the far end and shoot

back up, often not using a receive cable at all, figuring they

get the far end connector on the second test. But when you

disconnect the launch cable (and/or the receive cable) you lose

the connection you want to test in the other direction! As for

using the same OTDR, every OTDR is different and the results you

get may be significantly different, esp. if they are not

calibrated recently - and few OTDRs are ever calibrated.

Tracing Fibers

Q: I’m looking for an inexpensive, but reliable method

to quickly and easily identify terminated and unterminated SM

and MM fiber, perhaps something similar to a tone and probe used

for copper cabling. For example, I found a unterminated

coiled fiber cable and would like to use it, but there are

several unlabeled, terminated and unterminated fiber cables at

the other end. Is there an inexpensive universal tool to

simply and easily find the cable/s I’m looking for?

A: Your best bet is a

visual fault locator (VFL) but you do not need a bare fiber

adapter, just a unterminated connector. You will need to strip

the fiber and preferably cleave it, but that can be done off the

end of the connector. Just scribe the fiber and pull straight

away from the connector. That should give a cleave good enough

for using a VFL to trace fibers.

Equipment

Specified At 1310nm and 1300nm Compatible

Q: Can a switch or SFP module specified at 1310nm GBIC

connect to another switch or SFP that has is specified at 1300nm

GBIC?

A: No problem - there

is no material difference in 1300nm and 1310nm - it's just

jargon. The 1300/1310nm confusion has been part of fiber optics

for 30 years. Basically, there is no real difference in the

wavelengths except for traditional nomenclature. The

nomenclature evolved to this - if you said 1310nm, it was

assumed you were talking about lasers, but if you said 1300nm,

it was assumed you meant a LED!

Color Code For Hybrid Cables

Q: Is there a standard color code for the jacketing of

a hybrid all optical cable, one that has both single mode and

multimode optical fibers in it?

A: No, it has to

be spelled out on the cable. We could use a standard however. We

know plenty of people who got SM and MM confused in a hybrid

cable.

Passive

OLANs in Hotels And Resorts

Q: Are passive OLANs a good choice for hotels or

resorts?

A: Passive Optical LANs

are enterprise networks based on fiber to the home (FTTH)

technology not Ethernet over structured cabling. The FTTH

network is usually using GPON standard equipment over one

singlemode fiber with passive optical splitters that provides

basic Level 1 and 2 network functionality. This is not Ethernet

but carries Ethernet over the GPON protocols at 2.5G downstream

and 1.25G upstream.

Passive OLANs offer several advantages over conventional

Ethernet switches and structured cabling, including much less

cost (~50% capital expense and ~20% operating expense),

much lower space requirements (see the link to the library

photos below and note the two racks of equipment that support

4000 drops), longer distance requirements (to 20km), easy

expansion (these are systems designed for hundreds of thousands

of users) and easy management (when you have hundreds of

thousands of users, that’s important.)

For hotels, convention centers and similar facilities, the ease

of upgrading to a passive OLAN is a big advantage - one fiber

goes from the computer room to a splitter where it can serve 32

switches of 4 ports each. That’s right, one fiber can support

128 users! It can support anything that a network can - wireless

access points, security cameras, secure entry systems, VoIP

phones or POTS phones - anything that will run over a

conventional network.

Equal Fiber Lengths in Duplex

Links

Q: In a fibre system using separate cables for receive

and transmit, do the cables need to be the same length. Do the

patch leads need to be the same length?

A: The answer is “no”

within reason. Duplex signals are asynchronous by design so a

small difference should not cause problems. For some protocols,

very large differences might be a problem, but certainly not the

small differences in fibers in a cable or patch cord variations.

Even in a long OSP loose tube cable, there are variations in the

length of fibers, as much as +/-1%, because the fibers are loose

in the cable to prevent stress, so at 100km, the difference

could be significant. Networks allow for this.

Mixing

OS1 and OS2 Fibers

Q: Can I splice OS2 pigtails to OS1 fiber?

A: OS1 and OS2 are

identical geometrically (same core and clad size) but OS2 has

been processed to remove more OH+ (water ions) to reduce the

attenuation at the water peaks for use with coarse wavelength

division multiplexing. See

http://www.thefoa.org/tech/ref/basic/fiber.html

There is no problem mixing them in a system because other than

the reduction of the water peaks, the fibers are the same and

can be joined with no excess loss.

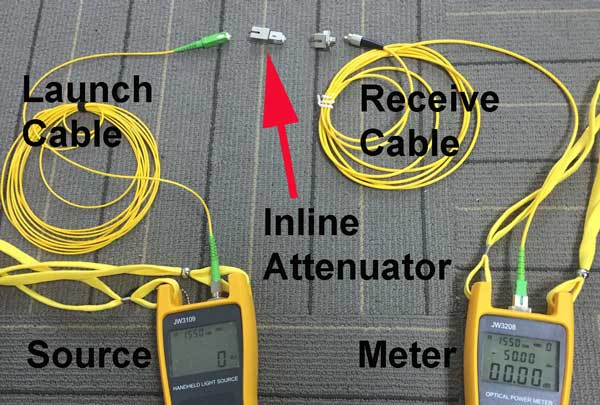

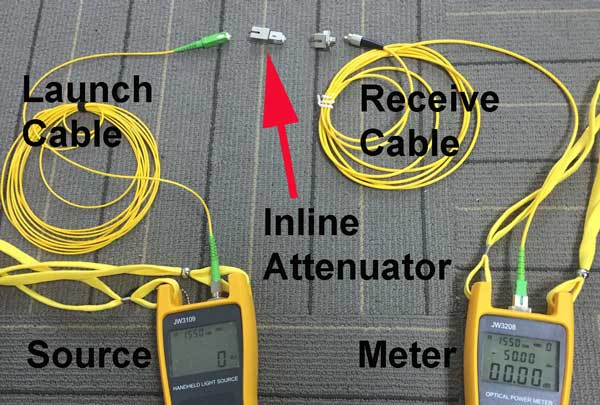

Testing

Attenuators

Q: How do I test an inline attenuator (receptacle on

one end and connector on the other)?

A: Here is the

procedure to test an attenuator:

This attenuator only works properly between two cables to add

attenuation so if you test directly connected to a power meter

it may not be correct. Here is how it is used:

————————————C-AAAAC=C——————————

Where C is a connector, -AAAAC is the attenuator with a

receptacle on the left and a connector on the right, and = is a

separate mating adapter or receptacle. C———————————C is a cable

with connectors on each end. Source- is a source and -Meter is a

meter

Test it like this:

First measure the output of the source with a cable as

the “0dB” reference. Use at least a 2m cable and put a

50mm loop in the cable. Remember you need SC/APC connectors on

the cables mating to the attenuator.

Source-C——————50mm loop———————C -Meter

Attach the receptacle end of the attenuator to the cable, then

use a mating adapter to attach a second cable to the attenuator.

Attach the meter to the end of the second cable to measure the

loss.

Source-C——————50mm loop——————C-AAAAC=C————————————C-Meter

Be sure to put the loop into the cable attached to the source.

Be sure your two cables are low loss and everything is very

clean.

And here is the photo the person asking sent us when they did

the test:

Calibrating

An OLTS

Q: I have a question about the OLTS - do you have to

recalibrate it every day ?

A: Any optical loss

test set needs to be calibrated for “0dB” whenever anything