Total Internal

Reflection - The Basic Principle of Optical Fiber -

And Fiber Numerical Aperture

Background:

Optical Fiber

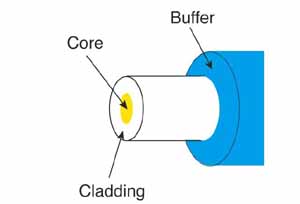

Optical fiber uses the optical principle of "total

internal reflection" to capture the light transmitted in

an optical fiber and confine the light to the core of

the fiber. An optical fiber is comprised of a

light-carrying core in the center, surrounded by a

cladding that acts to traps light in the core. Glass

fiber is covered by a plastic buffer coating that

protects it from the environment and allows easy

handling for splicing or termination.

The index of refraction of glass or any optical material

is a measure of the speed of light in the material and

changes in index of refraction are what causes light to

bend - as shown in this photo of a plastic rod in a

pond:

Beyond

a certain angle, the refraction will cause light to be

reflected from the surface. Optical fiber uses this

reflection to "trap" fiber in the core of the fiber by

choosing core and cladding materials with the proper

index of refraction that will cause all the light to be

reflected if the angle of the light is below a certain

angle. We call that "total internal reflection."

There

is an angle that for any given fiber defines total

internal reflection. At higher angles a ray of light

will still be refracted but not enough to be reflected

back into the core, so it is lost in the cladding of the

fiber. Below that angle, it will be reflected back into

the core of the fiber and transmitted to the end of the

fiber. The angle of total internal reflection defines

the "numerical aperture" (NA) of the fiber, a standard

fiber specification.

You can demonstrate this principle with a large plastic

rod (~25mm/i" diameter) and a laser pointer - a powerful

green laser works best.

To duplicate this experiment, you need a plastic rod

(Acrylic rods ~25mm/i"

diameter are available from online sellers. The end used

for the laser needs polishing to remove the saw marks on

most commercially available rods, so first use some very

fine polishing paper (1200-3000 grit) then finish with

microfinishing polishing film (30-3 microns) or

polishing compound (toothpaste, jewelry of auto

polishing compounds.) You should end up with a

transparent end.

Total internal Reflection In Action - Step Index

Multimode Fiber

Step index multimode fiber was the first fiber

design. The core of step index multimode fiber is made

completely of one type of optical material and the

cladding is another type with different optical

characteristics. It has higher attenuation and is too

slow for many uses, due to the dispersion caused by

the different path lengths of the various modes

traveling in the core. Step index fiber is not widely

used - only POF and PCS/HCS (plastic or hard clad

silica, plastic cladding on a glass core) use a step

index design today. POF is mainly used for consumer

audio and TV links.

Let's Do The Physics And Math

Total internal reflection is a principle described

by Snell's Law of optics. Snell's law describes how

light bends when traveling through the boundary of two

different optical materials, such as air and water as

shown in the photo of a pole in water above. Here is the

more scientific definition.

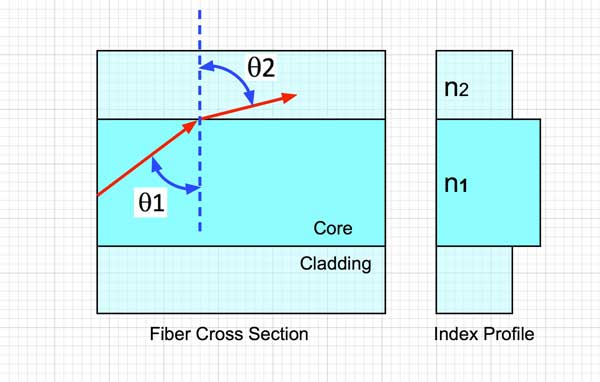

In the drawing above, the left shows a section of an

optical fiber with a ray of light. On the right is a

diagram of the index of refraction of the glass in the

fiber. The core glass is n1 and the cladding glass is

n2, and the core glass is of slightly higher refractive

index, ~1.46 to the cladding at ~1.45.

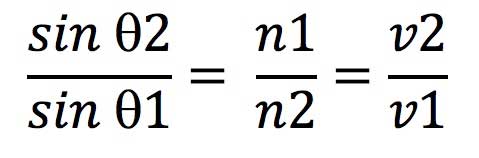

Remember basic trigonometry? The sine is the ratio of

the side of a right triangle to the hypotenuse - the

long side opposite the right angle. The refractive index

of the glass (n) is defined as the ratio of the

speed of light in a vacuum (c) to the actual speed of

light in the material (v) like this:

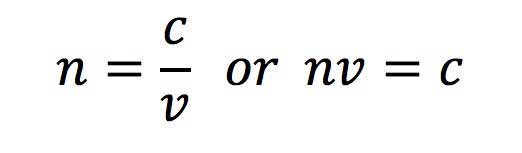

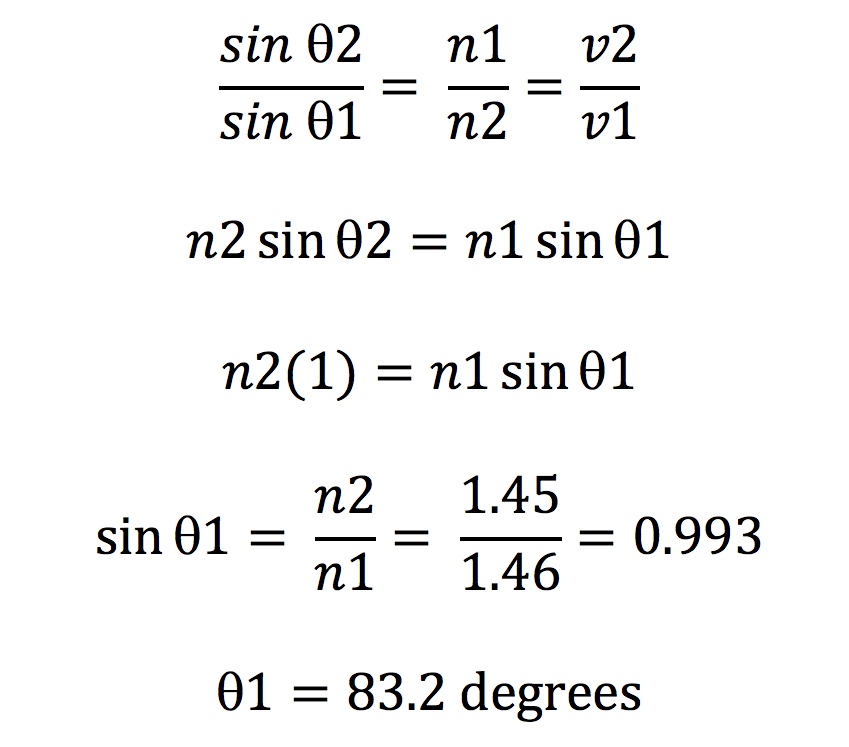

Using Snell's Law, we can calculate the angle at which

an optical fiber begins total internal reflection, which

happens like this drawing below, when the refracted ray

lays along the boundary between the core and the

cladding. We'll do this for a core index of 1/46 and a

cladding index of 1.45, the values we discussed above.

We need to manipulate the equations somewhat.

That indicates that a ray 6.8 degrees off axis (90 -

83.2 degrees) or less will see total internal

reflection. Another way of thinking about it is the

acceptance cone of the fiber is twice that angle or

about 14 degrees. This also process also defines the

definition of the NA or numerical aperture of the fiber,

but the calculation used is a mathematical manipulation

of the critical angle calculation.

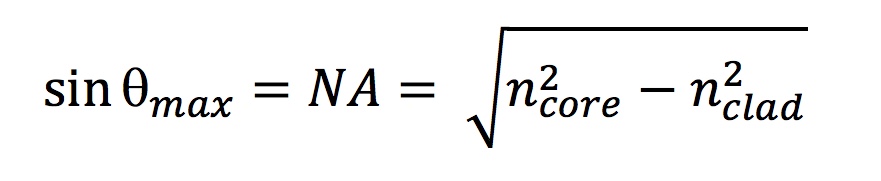

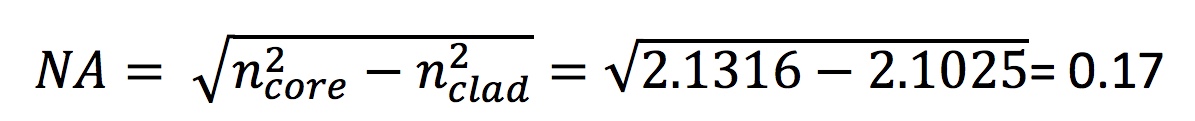

The numerical aperture of an optical fiber is an

abstract term for the acceptance angle of the fiber. If

we continue using the fiber we define above, the

equation becomes:

That's

a half angle of 9.8 degrees when used to calculate the

angle - the total cone angle is ~20 degrees..

Table of

Contents: The FOA Reference Guide To Fiber Optics

|