- Frequently

Asked Questions On OTDRS And Hints On Their Use

OTDRs, also known by their technical name optical time

domain reflectometers, are valuable fiber optic testers

when used properly, but improper use can be misleading

and, in our experience, lead to expensive mistakes for

the contractor. We have been personally involved in

several instances where misapplication of OTDR testing

has cost the contractor as much as $100,000 in wasted

time and materials. Needless to say, it's extremely

important to understand how to use these instruments

correctly.

What Is The Difference Between OTDR Testing And

Insertion Loss Testing?

An insertion loss test made with a light source and

power meter is a simple test that is similar in

principle to how a fiber optic link works. A light is

placed on one end of the cable and a power meter

measures loss at the other end, just like a link

transmitter and receiver use the fiber for

communications.

An OTDR, however, works like RADAR. It sends a pulse

down the fiber and looks for a return signal from fiber

backscatter and reflections from joints, creating a

display called a "trace" or "signature" from the

measurement of the fiber. From this trace, the OTDR

calculates fiber length, attenuation and joint loss. So

it does not “measure” loss directly, it implies it from

the trace.

When is OTDR Testing Appropriate?

The answer to this question has several aspects.

Let’s start with “What are we trying to test?”

OSP: In a long outside plant cable with many splices,

the OTDR is used to ensure that the cable has not been

damaged during installation and each splice is properly

made. Results are archived with other documentation to

be available if restoration is necessary in the future.

Later OTDR testing may be used for troubleshooting

problems like finding locations of cable breaks caused

by dig-ups. Generally, OSP networks are also tested with

a LSPM (light source and power meter) also called an

OLTS (optical loss test set.)

Premises: Premises cabling, however, has short cable

runs and almost never includes splices, so the

requirement of OTDR testing appears to be as an

alternative to insertion loss testing with a light

source and power meter, which in reality, is

inappropriate.

We recommend that insertion loss testing be done even

when OTDR testing is required by installation contracts.

In our experience, OTDR testing of premises cabling

systems is often required by users who do not really

understand when OTDR testing is appropriate or even what

an OTDR is. A knowledgeable contractor should be able to

educate the user on proper testing requirements.

New international testing standards, however, accept

both OTDR testing and insertion loss testing, even for

short premises multimode cable plants. The differences

in the measurement techniques used by OTDRs and a light

source and power meter means that OTDR testing,

especially on longer premises cable plants with higher

loss, may not be comparable to measured insertion loss

or the actual loss the communications system will

experience.

The international standard that allowed OTDR as well as

LSPM (light source and power meter) testing based that

decision on tests performed on cable plants appropriate

for 10G Ethernet which had losses of <2dB. In the

real world, multimode cable plants in premises

installations can have losses of 5-10 dB or more. OTDR

tests will generally not correlate with LSPM tests (or

often with other OTDRs!) which test the cable plant more

like how the cable plant is used by communications

equipment, and usually OTDR results are lower, setting

up the network owner for a problem when the

communications electronics are installed.

For this reason alone, we recommend that insertion loss

testing be done even when OTDR testing is required by

installation contracts.

Most of the technical calls we get at FOA regarding

problems using OTDRs on premises cabling systems are

caused by users who don't know what an OTDR is requiring

them for testing their installation just because

somebody told them to or they assume a bigger, more

expensive instrument gives better data.

Next: What Can The OTDR “Test”?

OTDRs use an indirect measurement process, have poor

length resolution and unique measurement errors that

limit its accuracy in testing cable plants. It is not

considered a replacement for insertion loss testing by

knowledgeable fiber optic personnel.

From a more technical standpoint, the first and most

important consideration for OTDR use is the length of

the fibers to be tested. Most OTDRs are designed for

long cable plants, especially singlemode OTDRs, and may

be inappropriate for short cables. Some multimode OTDRs

are now usable for short length multimode premises

cables but only if they are properly set up before use

and launch and receive cables have connections with low

reflectance. Furthermore, on short cables or even

relatively long ones with highly reflective events,

“ghosts” caused by the high reflectance

OTDR measurement of joint lost are directional,

dependent on the backscatter coefficient of the fiber,

causing measurement to vary by 0.25 dB or more depending

on direction.

If you are looking to test a cable plant to see if it

will support a communications system’s loss budget, you

do not want OTDR testing. If your network is short, the

OTDR will not give you valid data.

The second most common tech question we get at the FOA

is from people trying to use an OTDR when it’s

inappropriate.

Do I Need Training To Use An OTDR?

"My OTDR manufacturer tells me its fully automatic and I

just push a button and it gives me a PASS/FAIL result

like my “Cat 5” tester. They say I don’t need any

training."

Let’s just say that the majority of calls we get at the

FOA involve OTDRs being used by people who are ignorant

of their use, either trying to use them for cable plants

that are too short or full of ghosts, their launch

cables are too short, the setup wrong, or they simply

don’t know how to interpret the OTDR trace. We have many

examples including one instance where over $100,000

worth of cable was rejected and pulled out when it was

perfectly OK but the OTDR user did not understand the

trace. We have had calls from people trying to test 70m

singlemode cables without a launch cable, MM cables with

SM OTDRs and vice versa, and many more.

If you are using an OTDR without training, you are going

to have big problems.

- Why

Do I Need A Launch Cable On The OTDR?

- OTDRs are

always used with a launch cable and may use a receive

cable. The launch cable, sometimes also called a "pulse

suppressor," has two major reasons for its use:

- 1. The launch

cable allows the OTDR trace to settle down after the

test pulse is sent into the fiber so you can analyze the

beginning of the cable you are testing. The large event

you see right in front of the instrument on the OTDR

trace is caused by crosstalk within the instrument and

reflectance from the connector on the face of the OTDR.

The long recovery time from this overload pulse means

the OTDR cannot make any useful measurements near the

instrument itself. The launch cable has also been called

a "pulse suppressor" because it allows time for the OTDR

to settle down from this initial overload. If possible,

singlemode OTDRs should have APC connectors on the front

panel to reduce reflectance. Also a short connection

cable attached to the OTDR before the launch cable that

never gets removed from the OTDR prevents excess wear on

the panel connector.

- 2, The launch

cable provides a reference connector for the first

connector on the cable under test to determine its loss.

A receive cable may be used on the far end to allow

measurements of the connector on the end of the cable

under test also.

What Is The Resolution In Length Of The OTDR?

Most OTDRs have a display range digitized to about

10-20,000 parts, so on a 20km range, the display

resolution is 1m, or on a 2km range it would be 0.1m.

The actual resolution of the OTDR is usually thought of

as its ability to distinguish between two points on the

cable, like intermediate patchcords or closely spaced

splices. The actual resolution is determined by the

width of the test pulse and the bandwidth of the OTDR

receiver and is usually much longer than the display

resolution. A 100ns pulse, for example, equals about

20m, but the depending on the shape of the test

pulse, the OTDR may not be able to distinguish events

2-3 times that length.

- See the demonstration

below for a way to prove this to yourself.

I Have Heard The OTDR Measures Fiber Length, Not

Cable Length. How Do I Correct For That?

First, what are the sources of error? The OTDR uses the

speed of light in the fiber (from the index of

refraction) to calculate the length of the fiber. Also,

most cables have 1-2% excess fiber (less on ribbon

cables) to prevent fiber stress under cable tension.

Some manufacturers of cable can provide that information

for your testing. If you do not know the index of

refraction/velocity of propagation or the ratio of

excess fiber, you can estimate it or, if you have a long

spool of cable, calibrate it.

Just measure the fiber on the spool of cable with the

OTDR, then look at the cable jacket for length markings

to get the actual length of the cable from the printed

markings at each end of the cable. Use the OTDR’s

calibration feature to set the index of refraction to

the value that makes the OTDR read the same as the

marked length of the cable.

Directional

Results Can Be Confusing: I am testing a cable with

OTDR. I have a limit 0.2 db loss per splice. I use bi

directional analysis. In some fibers from A>B

direction i have 0.25 loss but in B>A it doesnt show

up that splice at all. I changed the pulse width but

nothing happened. Any ideas?

You are

seeing the directional differences. For a splice with 0.25

dB loss in one direction and 0 dB in the other, the

average is (0.25+0)/2 = 0.13 dB loss. If you shoot in both

directions and overlay, the software should recognize that

there should be events in both directions, input a "0 dB"

event and average accordingly. Most OTDRs also allow

setting a threshold for detection of events and that must

be set correctly to recognize events. There are many times

a splice is undetectable in an OTDR trace due to good

splices and the simple fact that the OTDR measurement

technique itself is limited.

How can

we differentiate a ghost from a real event?

A ghost

will not have any loss, it will be at equal distance from

a highly reflective event (look for repetition), tends to

be in the middle of noise after the end of the cable.

What

are good values to set a OTDR to for PASS/FAIL?

Splice threshold

Reflectance threshold

Slope threshold (slope is attenuation coefficient)

End threshold (depends on whether you 1) use receive

reference cable which would be a normal connection loss or

2)the length of the cable and the noise floor of the

measurement. Best to make sure the trace is not noisy to the

end and have 2-3dB from the cable backscatter level to the

noise floor.

Application

|

Splice

|

Connector

|

Reflectance

|

Attenuation

|

Singlemode

long distance (>5-10km)

|

<0.1dB

(fusion)

|

<0.3dB

|

>-40dB

(that means -41dB or more)

|

0.4dB/km

at 1310nm, 0.25dB/km at 1550nm

|

SM

short links

|

<0.1dB

(fusion)

|

<0.3dB

|

>-50dB

(that means -51dB or more)

|

0.4dB/km

at 1310nm, 0.25dB/km at 1550nm

|

MM

|

0.3dB

(fusion or mechanical)

|

<0.5dB

|

>-30-35dB

|

3.0

dB/km at 850nm, 1dB/km at 1310nm

|

- Uncertainty

of OTDR Test Results

- We received a

call from a contractor who had tested a cable plant for

an end user using an OTDR. The user had several others

do the same test and got different results, not widely

different, but different enough to make him wonder why.

The same thing happens with OLTS testing too, but for

slightly different reasons. This conversation inspired a

short tutorial which follows:

- Two Types of

Measurement Errors

-

Measuring a physical parameter always involves errors.

Unfortunately you never know the real value to begin

with, so all you can do is to estimate the error based

on the possible sources of error in making the

measurement. There are two types of errors, random and

systematic.

-

Random errors are what you see when you make a

measurement multiple times and get a slightly different

value each time. Hook up your instrument and make the

measurement, disconnect and try again. Each time, the

result will be slightly different. Generally one should

make several measurements, average them and use the data

to calculate the random error, called standard

deviation, to understand the uncertainty of the

measurement.

-

Systematic errors are how the average measurement

differs from the real value, which can be caused by some

problem in setup or calibration. Unfortunately, it’s

hard to determine the systematic error, but some

possible ways exist sometimes.

- Let’s look

at OTDR measurement uncertainty from both a random

and systematic viewpoint.

- Random Errors

-

Testing loss with an OTDR requires a launch cable that

connects to the fiber in the cable under test, taking a

trace and analyzing the trace, either manually or using

some preprogrammed auto-test function. This leads to

several random errors in loss measurement which may

include:

- 1.

Variation in loss of the connection of the launch cable

to the cable under test caused by alignment variations

each time it’s connected, dirt, temperature, etc.

- 2.

Changes in stress of the launch cable or cable under

test which can be caused by temperature variations or

physical movement of the cable.

- 3.

Changes in the mode power distribution of launched

pulses which can affect both multimode and

singlemode cables (short SM may not be single-mode-it

may take hundreds of meters!)

- 4.

Noise in the OTDR trace, with the effect greater effect

with less averaging.

- 5.

How the user sets the markers on the trace for each

measurement. This is affected by pulse width (risetime)

and the reflectance from an event which can overload the

OTDR and cause difficulties in determining where the

fiber baseline is located.

- Systematic

Errors

-

When you set up the OTDR, you have to make certain

set-up decisions, including range, wavelength, fiber

glass index of refraction, pulse width, number of

averages, etc. that affect the measurement uncertainty

for every measurement.

- Length

Measurement

- 1.

The range may affect the time base of the OTDR which is

used (along with index of refraction) to calculate the

length of the fiber.

- 2.

The index of refraction (n) is a direct expression of

the speed of light in the fiber (V=C/n). Distance is

calculated as “time X speed.” Most OTDR users use a

generic value, but sometimes the actual value for the

fiber being tested is known.

- 3.

Each cable has excess fiber, typically ~1%, to prevent

stressing the fiber when pulled. The OTDR measures the

length of the fiber, not the cable. It can be calibrated

for the cable under test if one knows the length of the

cable and uses that to calculate a cable-specific index

of refraction.

- 4.

The pulse width may cause systematic errors in the

measurement of length, since wider pulses have longer

risetimes which make placing the markers consistently

more difficult.

- Loss

- 1.

Setting markers for measuring loss is affected by the

width of the test pulse. Longer pulses have longer

risetimes which make setting markers consistently more

difficult. Wider pulses cause greater reflectance from

connectors and affect both the shape of the reflected

pulse and the shape of the return to the fiber baseline,

causing uncertainty on how the markers are set. Noisy

traces are wider, which can lead to systematic errors.

- 2.

Manually setting markers generally will introduce random

errors, as the operator sets their location each time,

but can introduce systematic errors due to the way the

operator typically works.

- 3.

Auto-test programming may introduce systematic errors

depending on the pulse width, reflectance, range,

averaging, etc. Generally auto-test should not be used

until it has been compared to manual analysis.

- 4.

Connectors on different launch or receive cables will

change the measurements systematically.

- 5.

The length of the launch cable may affect SM or

multimode measurements. A SM launch cable should be

500-1000 m long to ensure the test signals are

singlemode. Multimode fiber will change mode power

distribution with length.

- 6.

Any mode conditioning on a MM cable (e.g. mandrel wraps)

will affect the modal conditioning on the downstream

part of the test where the test pulse from the OTDR goes

out from the OTDR. On the return backscattered light,

the fiber modes will be fully filled.

- 7.

Instrument calibration will cause systematic errors. Few

users ever calibrate OTDRs, but the time base and

linearity of the amplifiers can affect the measurements.

- Uncertainty of

Results

- So what can

you expect? Length may vary by several percent on

different OTDRs. Loss can vary by several tenths of a dB

on short lengths and proportionally more on long cable

plants for different OTDRs.

Fiber

Loss Errors On Short Cables

A

contractor had a customer who required OTDR testing of

installed cables, including measuring the attenuation

coefficient of the fibers in the cables. Fiber attenuation

readings well above the expected values and those required

by the contract with the user. Under some questioning, we

found out the cables were very short, so the traces looked

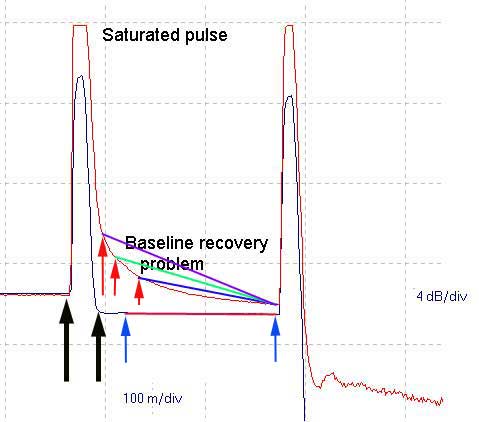

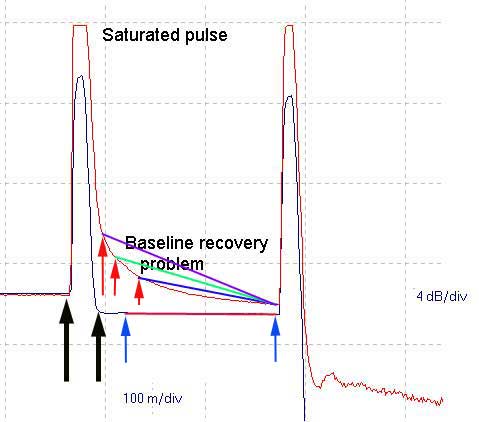

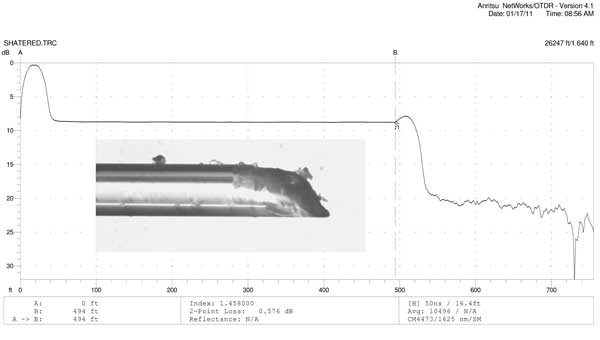

like this:

The problem was the recovery from the reflectance overload

at the connection between the launch cable and the cable

under test was not recovering quickly, so there was not

enough usable fiber trace to get a valid reading of the

slope of the fiber which is the attenuation coefficient.

When the marker is placed on the tail of the recovery pulse

(the red arrows), the

slope of the measured trace is much higher than the actual

slope of just the fiber attenuation, leading to values that

cause the fiber to fail testing even if it is good. To get a

valid reading the pulse must fully recover to the baseline

of the fiber as shown by the black arrows and then the

markers can be placed as shown in the

blue arrows to make a fiber attenuation coefficient

measurement.

But to make this measurement, the fiber must be long enough

and the OTDR resolution high enough.

Testing

Bare Fibers With OTDR

Q: We are starting to test some OPGW cables. We

have an OTDR but we don’t find some reusable connectors.

If we have to test an OPGW with 48 fibres, we can’t set up

48 SC connectors!

Are there some reusable connectors in the commerce?

A: I assume you

mean you need to test with a bare fiber on the OPGW. For

testing bare fiber, use a splice, not a connector. Have a

long pigtail on the OTDR as a launch cable, long enough

for the test pulse to settle, say 100-500m, then use a

splice for a temporary connection. You can fusion splice

the fibers then cut the splice out or use a removable

splice like the Corning Camsplice

(http://catalog.corning.com/opcomm/en-US/catalog/ProductDetails.aspx?cid=&pid=17929&vid=18219)

If you use a mechanical splice, you need a high quality

cleaver just like with fusion splicing and after several

uses, you need to add more index matching gel or liquid -

mineral oil works OK. See

the FOA page on Testing

Bare Fiber.

- OTDR

Calibration

Q: I read on your website information about

ODTR, and I'm curious if you could offer some more

information. I am interested in all compatible standards

considering OTDR Calibration. So far I managed to find

out that there is IEC 61746-1 standard for Calibration,

and also TIA/EIA-455-226 which is adoption of IEC

61746-1. And I concluded that those 2 are surely

internationally approved and do the same thing. I found

in some website the offer for calibration performing

both NIST traceable, and TIA 455.

I could not find out what is relation between TIA and

NIST traceable calibration standards ( if there are

any), is it the same or those 2 are compatible (if

u use one of those for OTDR calibration it is

enough)or those 2 are different and you need to perform

both.

A: OTDR

calibration is not a simple task like calibrating power

meters.

Calibration of OTDRs involves the time base for the OTDR

that uses the index of refraction of the fiber or

nominal velocity of propagation (NVP) of light in the

fiber to calculate distance and the linearity of the

power measurement of the receiver. NVP is, of course,

dependent on wavelength.

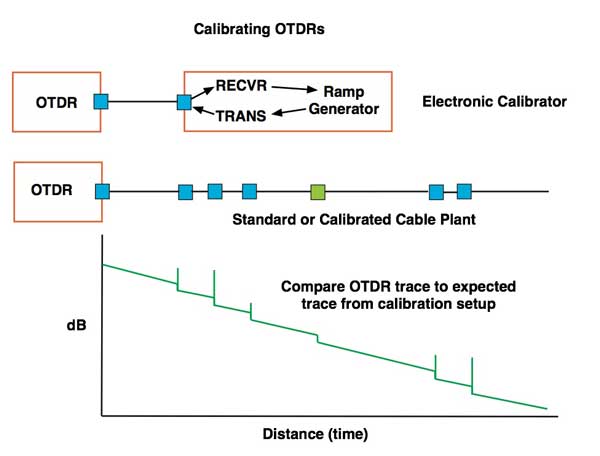

The debate over OTDR calibration has always been whether

a standard fiber method of calibration that involved

calibrating every OTDR to read the trace identically or

an electronic method of calibrating the OTDR timebase

and receiver was a better method.

NIST was approached for OTDR calibration in the 1980s

and considered making a transfer standard for use in

calibrating OTDRs. It was originally intended to be a

sample fiber of known index of refraction and length

with splices and connectors of known loss. However the

project was never completed as it would require many

different "standard fibers" and could not be made

agreeable to all parties.

Others thought an electronic/optical calibration based

on a device that would simulate the trace from a cable

was more accurate. That involved an instrument that

would be triggered by the OTDR test pulse and would then

generate an optical power declining over time to

simulate the OTDR trace. Both these methods have been

used since, but NIST never produced an OTDR calibration

system like they did for optical power meters (I worked

on that one myself.)

There is IEC 61746-1 standard for Calibration, and also

TIA/EIA-455-226 which is adoption of the IEC document.

Other than the IEC document, I know of no other

standards or traceable calibration by a national

standards lab.

Since there is no standard fiber, perhaps the best

method of "calibrating" the instrument is sending it

back to the manufacturer who can test the timebase and

receiver linearity and confirm their performance. And,

of course, they can do all the other updates for the

given model of OTDR.

Then it is left to the user to choose the proper NVP or

index of refraction for the fiber or calibrate it for

the cable length (including average excess fiber in the

cable.) And deal with the differences in backscatter

that cause directional errors in loss of splices and

connections.

Or maybe, one realizes that OTDRs are better considered

"qualitative" instruments instead of "quantitative"

instruments and just accept the fact that the data has

quite a bit of uncertainty.

I’m Troubleshooting A Break In A Long Cable Run But I

Don’t Know The Correction Factor For Fiber Vs Cable

Length. What Can I Do?

Here is a perfect example of why you need cable plant

documentation. If you have the data from the original

design and testing, you should have the actual length of

the cable plant. With that you can calculate the point

of the break very closely. Here is an example:

Let’s say we have a 10km cable with a break around 6km

from one end. From one end, the OTDR says the distance

to the break is 6500m and from the other end it says

it’s 4000m.

Total length of OTDR cable length: 6500+4000=10,500m

If the actual cable length is 10,000 m, the correction

factor is:

Actual length/measured length = 10000/10500 = 0.952 =

correction factor

Thus our 6500m measurement is actually 6500X0.952 =

6190m and from the other end it’s 3810m.

If you do not have documentation, try to calibrate the

OTDR using a section where you can get real length data

from the cable jacket.

Sometimes My Traces Show Big Reflections From The End

Of The Cable But Sometimes It Shows None At All. Why?

The reflection on the end of the cable depends on the

end of the fiber. If it’s broken and ragged, you will

see practically no reflection, but a perfectly cleaved

fiber will show a giant reflection peak.

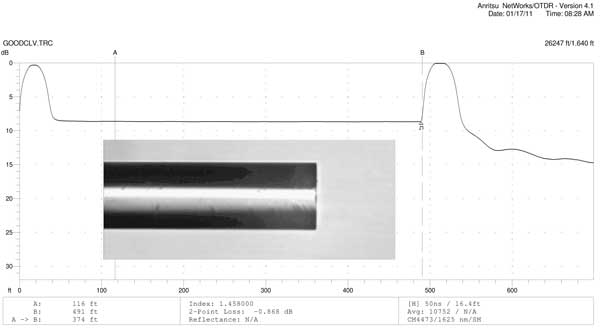

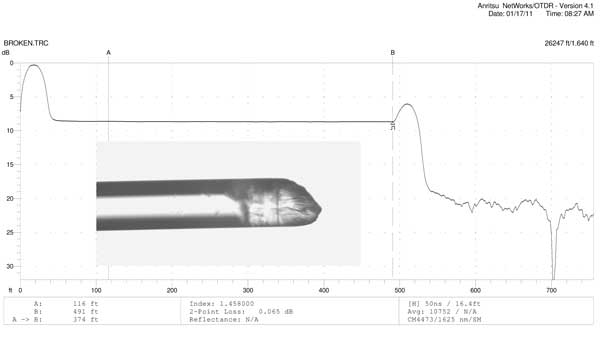

Look at these three traces:

Note how the cleaved fiber has a high reflectance,

reaching saturation on the OTDR trace

The broken trace shows a small reflectance.

The shattered fiber shows virtually no reflectance.

- Interpreting

OTDR End Reflectance Peaks (from Terry O'Malley)

Close

inspection of Fresnel Reflections (Reflectance

Peaks) May Yield Useful Information

by Terry O'Malley

When inspecting and analyzing Fresnels, particularly

at the end of a system, testing technician should pay

close attention to the trace of the recovery slope of

all Fresnels, especially the end of system Fresnel.

Sometimes it is possible to detect an upward, smaller

spike in the recovery slope before the trace goes to

the additional backscatter of fiber or into noise.

This can often be attributed to a second “end of

fiber” Fresnel close to the first Fresnel such as when

a patch cord is connected to an end terminal or a

cracked fiber is before or after a mechanical

connection. A typical situation would be when the

first Fresnel is generated by the fiber at the end

terminal and the in the recovery there is a small

upward point in the downward slope that can be the end

of fiber in connected patch cord.

This can be responsible for having two different

length measurements lengths from A to B and B to A for

the same fiber. From one end the OTDR reads to

the terminal Fresnel but does not read to the end of

the patch cord and from the other end it reads

distance through the patch cord. In this case

the difference should be close to the length of the

patch cord.

Caution: Some OTDR have anomalies in the

software that erroneously produce faulty recovery

slopes.

Actual traces demonstrating the information in a

reflectance peak.

This is a trace of the end of a fiber. Note the

structure in the reflectance peak.

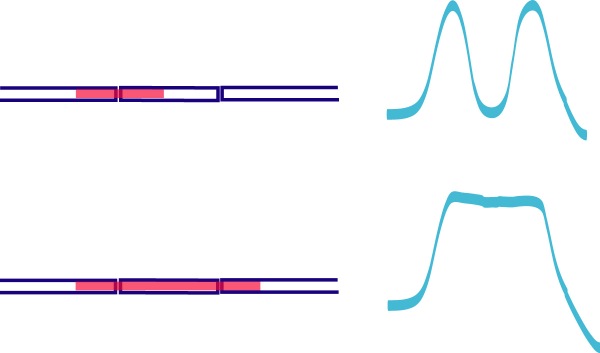

If you expand that peak, you can see structure in it.

That is because the end of the cable has a 10m

patchcord attached. It is too

short to be resolved by the OTDR, so the peak you see

is the merger of two peaks separated by 10m. The

drawing below shows

what happens when two events are too close for the

OTDR to resolve.

This is the same peak without the 10m patchcord. You

can see there is no structure in the peak.

How are OTDRs

Calibrated?

- Calibration of

OTDRs is a messy issue. There are many variables.

You can purchase OTDR calibration artifacts for

calibrating your OTDR but as far as I know, they are

generally not traceable to national standards labs.

Using fibers to calibrate an OTDR introduces errors.

Two parameters of the OTDR need calibration: dB and

length.

Calibration of the dB scale, used for measuring loss and

attenuation coefficient (which is also dependent on

length calibration) is complicated by the way the

instrument is used. For loss, the measurement is very

low in magnitude (~0.1dB) but fine in resolution (as low

as 0.001dB), so nonlinearities on a small scale along

the entire measurement range are the issue. Proper

calibration would include the linearity of the entire

measurement range which is virtually unknown.

For attenuation coefficient, the dB measurement is over

a longer range and can be done with a calibrated

artifact. But that calibration is wavelength dependent.

For length, it's a matter of time measurement in the

OTDR - distance is calibrated from the index of

refraction of the fiber or the group velocity of the

test pulse in the fiber. This can be done with a

calibration artifact - a fiber of known length and index

of refraction - but again the calibration is wavelength

sensitive.

You can get calibration artifacts from NPL in the UK,

but you need to know the calibration wavelength of your

OTDR and the characteristics of their artifact to make

corrections.

Another method uses a electronic calibrator - take the

pulse from the OTDR and trigger a delayed return pulse

to calibrate the distance scale and a optical ramp to

simulate the attenuation of a fiber. This removes the

unknowns associated with using a fiber and has been

championed by many scientific types.

Any OTDR manufacturers want to offer their wisdom?

Our thanks to FOA

Master instructor Terry O’Malley (

http://www.fiberopticsolutions.biz/)

for his advice and work creating the sample traces and

the following exercise.

Demonstrating OTDR Length

Measurement Capability

This testing exercise demonstrates that the OTDR is

extremely accurate “unto itself”. That is; not in actual

fiber length (IOR dependent) and defiantly not in sheath

length but it has some important usage when it comes to

troubleshooting.

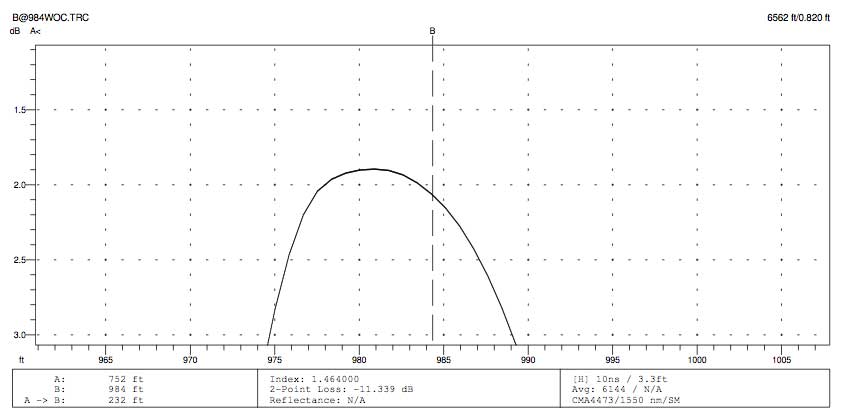

OTDR GNNettest 4000

Settings

Range 6kft

IOR 1.464

PW 10ns

Fiber Sections

Reel 1= <600 ft.

Reel 2= >1000 ft.

Reel 3= <1000 ft.

TEST 1 & 2

When the reels are connected consecutively (1-2-3) the

distance to the end Fresnel is within two (2) feet from

either direction. Demonstrates the repeatability of distance

measurements.

TEST 3

All three sections of fiber measured exactly the same length

from both ends.

Demonstrates the repeatability of distance measurements.

TEST 4

Cutting off the far end fiber in 1 inch sections. On the

third 1 inch cut off ( a total of 3 inches) the frenel

jumped back towards the OTDR test end one foot. On the

second set of fiber cuts it required 8 one (1 ) inch cuts to

get “behind” a sampling point to again move the Fresnel back

one sampling point in distance.

This demonstrates the resolution as it relates to sampling

points and distance accuracy.

TEST 5

A ten (10) foot cords was attached to the far end and the

distance reading to the far end remained the same as in test

1.

This demonstrates that the 10 foot cord was “hidden” in the

recovery of fiber reel 3’s end termini reflectance.

TEST 6

The 10 foot cord was then connected to the OTDR test cord at

the near end. The system under test measured an additional

10ft exactly.

This demonstrates that the 10 foot cord length could be

measured if not hidden in the end reflectance.

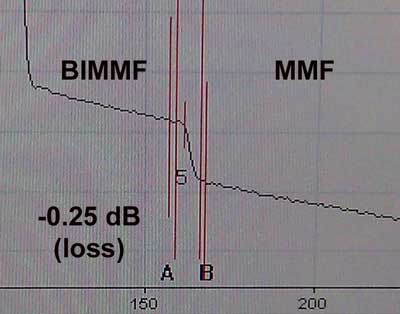

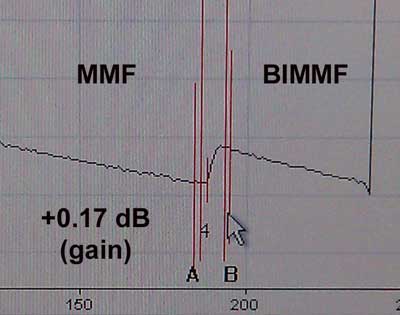

Do Multimode Fibers Show

Gainers Also?

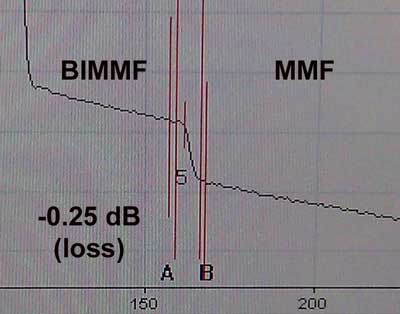

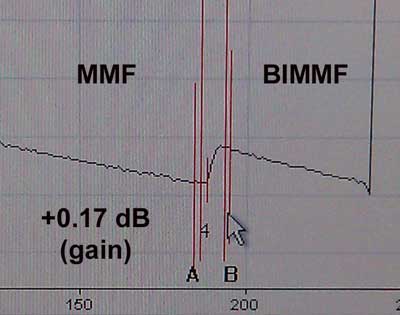

Yes they can. One way it happens is with a mix of regular

and bend-insensitive MM fibers. One cable lab shared

with us a pair of very interesting OTDR traces of what an

OTDR shows on a splice between BIMMF and regular MMF (see

below). Who would have guessed that MMF could show such a

gainer! This is just another proof that OTDR tests are NOT

indicative of actual cable plant performance!

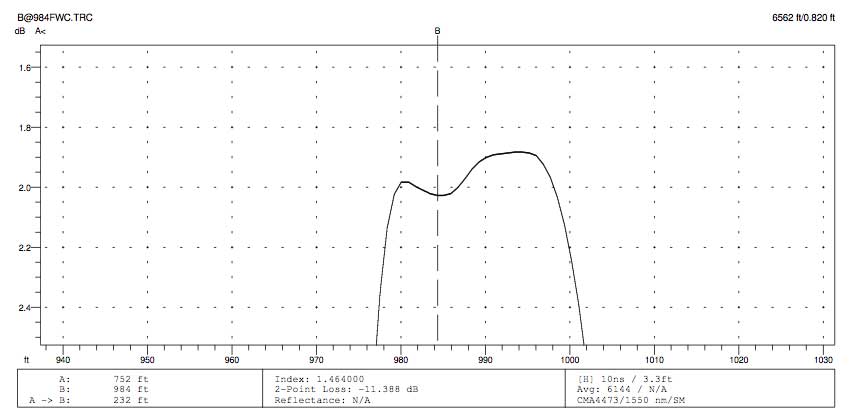

OTDR

traces of a joint between BIMMF and regular MMF. The

higher scattering of the BIMMF causes a big “gainer” in the

reverse direction, illustrating why OTDRs should not be used

to test cable plant loss. If you tested the end-to-end loss

of this link with an OTDR in one direction only, the loss

would have been 0.42 dB different than in the other

direction. If you averaged the two per normal OTDR practice,

the loss would be 0.04 dB, but with a backscatter gain of

0.21 dB, what loss is real with these two fibers?

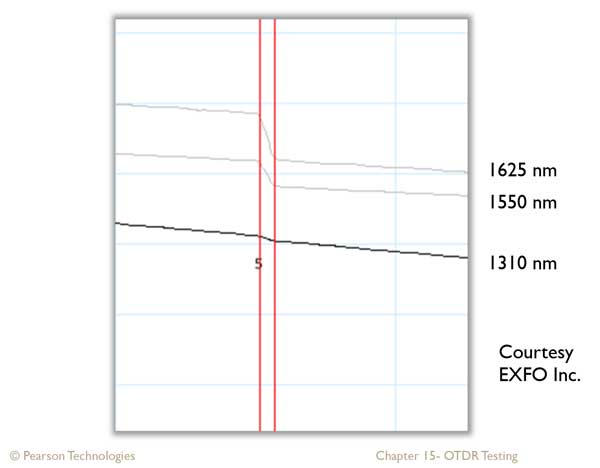

Finding

Cable Kinks Or Stress Points With An OTDR

One of

the classic reasons to use an OTDR is its ability to find

kinks in a cable or other areas where stress on the cable

will cause high loss. To illustrate this, we set up the FOA

Yokogawa OTDR (thanks again for the donation to the folks at

Yokogawa) with some SM cables and created these traces. The

cable shown is a 60m simplex cable.

First, here is a trace taken before inserting the "kink" at

1550nm. We used 1550nm because stress on the cable causes

more loss at longer wavelengths.

Notice how the reflective connectors cause a 20m+ dead zone

after the connection to the launch cable. To insert the kink

we put in a single bend with a bend radius of ~10mm and

clamped the cable to hold the bend. Then we got this trace:

Now you can see the kink at the halfway point in the cable,

a loss of 2dB. Note there is no reflectance peak, just a

sharp drop off on the trace. A kink tends to look just like

a fusion splice because of the lack of reflection that is

common with a connector.

How do we know it's a kink and not a splice? We can test it

again at 1310nm where the loss at the kink should be less.

Here is the trace at 1310nm:

As you can see, there no indication of a problem at the

lower wavelength. This illustrates that 1) the loss of the

kink is higher at longer wavelengths (it would have been

more loss if we had a 1625nm module for the OTDR) and 2) if

you are looking for stress caused by installation, you need

to use the longest wavelength available - 1550 or 1625nm for

SM, 1300nm for MM.

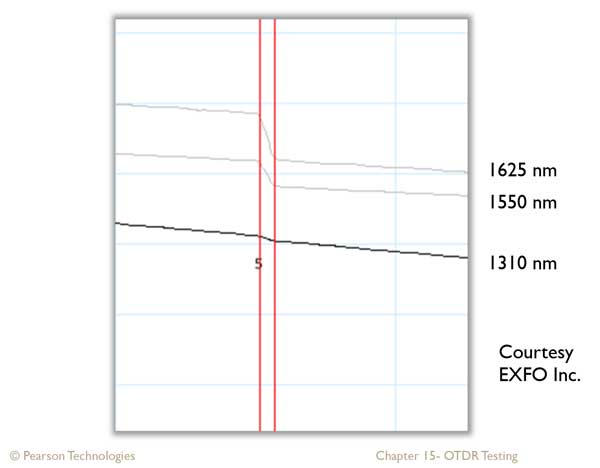

Here is a comparison from an EXFO OTDR furnished by Eric

Pearson.

Measuring

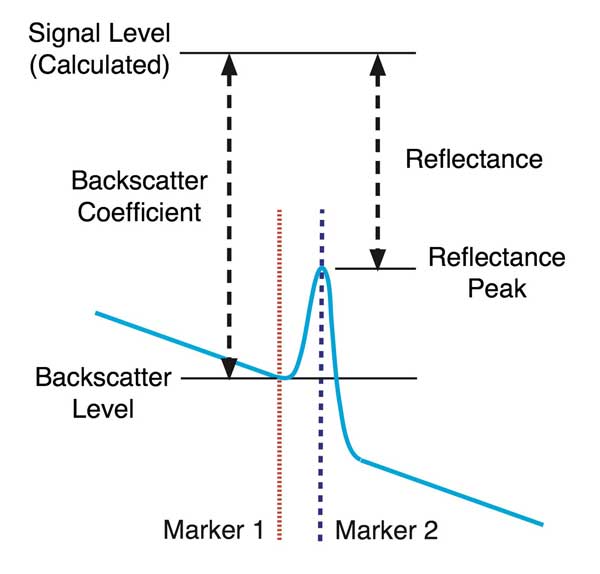

Reflectance And Optical Return Loss

Reflectance

In

an OTDR, the peak that identifies a reflective event is

measured and reflectance calculated. Higher peaks

indicate higher reflectance. In order to measure

reflectance, the peak must not saturate the OTDR receiver,

indicated by a flat-topped

reflectance peak (below.) For instance this is an OTDR trace

where reflectance cannot be accurately measured. It will

only indicate a

value less than actual.

Calculating

reflectance in an OTDR is a complicated process involving

the baseline

of the OTDR, backscatter level and power in the reflected

peak as shown in the diagram below. Since reflectance is

defined as a fraction of the power in the test signal, the

OTDR must calculate the test power from the backscatter

level of the fiber, based on the typical backscatter

coefficient of the fiber being tested.

The OTDR measures the backscatter level just before the peak

being measured, applies a correction for the pulse width of

the OTDR test pulse, then calculates the test signal level.

It then measures the power of the reflectance peak and

calculates the reflectance. The indirect way this is

measured causes reflectance measurements with an OTDR have a

fairly high measurement

uncertainty, but have the advantage of showing where

reflective events

are located so they can be corrected if necessary. By

choosing the

reflectance measurement and putting the right (blue) cursor

on the peak

of the reflection and the left (red) cursor just to the left

of the

reflection, the OTDR will measure the reflectance.

Optical

Return Loss (ORL)

The OTDR generally tests ORL by calculating the total all

the light reflected from reflective events plus the total

backscatter from the entire length of fiber being tested.

This ORL measurement is sometimes used as a specification

for very high speed systems as ORL can be a contributor to

noise in a transmission link. It is not a reflectance test

of an individual event and should not be confused with that

test.

- Want

to learn more? Try the FOA

Self-Study Program on OTDRs at Fiber

U.

- Return

To The FOA OTDR Tutorial

- Download the

free FOA OTDR PC

Simulator To Learn How To Use An OTDR

- See

the FOA Virtual Hands-On OTDR Tutorial

- Return

to the FOA Online Reference Guide Table of Contents

Return

to the FOA Guide Table of Contents

Return

to the FOA home page

|