|

Introduction

The

end

user, who owns and uses communications systems, often finds it

hard to

get information about fiber optics aimed specifically at them.

Industry

standards are written by and for manufacturers. Most training

material

is written to train installation techs, the group the FOA

focuses on

with most of its certification programs.

So the

FOA has created a special section of our website where end

users can

find answers to their questions on fiber optics or even find

out what

questions to ask. We think you will find this interesting and

useful.

We welcome your questions and feedback.

|

Getting

Started

In Fiber Optics

The FOA has several options to help you get started in fiber

optics. These are the way to get started.

Fiber

U -

FOA's free online training program

FOA

Online Tutorial on Fiber

Optics

Lennie

Lightwave's Guide To

Fiber Optics

Self-Study

Guide To Fiber Optics

|

- For

Potential Users Of Fiber Optic Communications:

- Should

you

use fiber optics for your communications system?

- What

are

its advantages and disadvantages?

- Isn't

fiber

optics still too new for everybody to adopt it?

- Is

it

hard to design and install fiber optic networks?

- Do

they

require maintenance?

-

- This

short

guide is designed to help answer those questions for users

pondering the choices and/or planning an installation and

provide links

to more in-depth information.

This guide covers all applications of fiber optics.

If your applications are primarily premises cabling, the FOA

has a

section of its FOA Online

Reference Guide that focuses on fiber, copper and

wireless for premises

applications. and another focusing on outside

plant fiber optics.

If you are new to fiber optic communications, the FOA Guide To Fiber Broadband

book can help you understand how fiber optics is the backbone of the

world's communications systems - landline, submarine and wireless. The book is available on Amazon.

|

Fiber

optic connectors from the 1970s , 1980s, 1990s, 2000s (bottom

to

top)

Fiber

optic connectors from the 1970s , 1980s, 1990s, 2000s (bottom

to

top)

|

- 1. Introduction

One often sees articles written about fiber optic

communications

networks that implies that fiber optics is "new." That is

hardly the

case. The first fiber optic link was installed in Chicago in

1976. By

1980, commercial long distance links were in use and fiber

optic data

links for computers were available. Since that beginning, fiber

has become

very commonplace - one should say dominant - in the

communications

infrastructure.

The Internet is 100% fiber optics. On land and

under the oceans, fiber optic cables are connecting users to data

centers around the world on fiber. Even inside the data centers,

communications is virtually all on fiber.

- If

you make a long distance call today, you are

undoubtedly

talking on

fiber optics, since it has replaced copper or

microwaves in virtually all the circuits

for long distance communications; only a few

subscriber lines are copper and even cell towers are connected on fiber.

Most large office

buildings have

fiber in the building itself. Only the last link to

the

home, office

and phone are not fiber and installations of fiber

to the

home are

growing rapidly.

CATV also discovered fiber optics, along with compressed

digital

video back in the 1990s. CATV systems have been converted to

fiber optic

backbones which allow voice and data transmission usig cable modems in

addition to video.

The LAN backbone also has become predominately

fiber-based.

The

back-end of mainframes and storage area networks

(SANs) are

almost

totally fiber. Only the desktop is a holdout, a

variety of copper and fiber used for desktop computers and WiFi for

mobile devices.

Fiber optics offers an unrivaled level of security. It

cannot be easily

jammed or tapped and is immune to interference. It is widely

used for

security cameras, perimeter alarms and other critical

systems in

military, government, utility and civilian applications.

Fiber optics really is the medium of choice for long

distance, high

bandwidth or secure communications. Lets look at why it is,

how to

evaluate the economics of copper versus fiber and how to

design fiber

networks with the best availability of options for

upgradeability in

the future. -

- 1.1

Its really all a matter of economics

Fiber optics has become widely used in telecommunications

because of

its enormous bandwidth and distance advantages over copper

wires or wireless.

Commercial systems today carry more phone conversations over

a pair of

fibers than could be carried over thousands of copper pairs

and can be

run hundreds or even thousands of kilometers between all-optical repeaters.

Material

costs, installation and splicing labor and reliability are

all in

fiber's favor, not to mention space considerations.

In CATV, fiber pays for itself in enhanced reliability and

the ability

to offer enhanced services. The enormous number of repeaters

that were once used in a

broadcast cable networks on coax cable were a big source of failure. CATV

systems' tree

and branch architecture means and upstream failure causes

failure for

all downstream users. Reliability is a big issue, since

viewers are a

vocal lot if programming is interrupted! The ability to

offer Internet

access using cable modems has created significant revenue streams for CATV

operators also.

For LAN and other datacom applications, the economics are

less clear

today, especially since most connections are on WiFi for mobile devices. As distances go over 50 to 100

meters and

speeds above 1 Gb/s, fiber is the best choice.

- Some

applications demand fiber. Factory floors are messy

electrical

environments where optical fiber, both glass and plastic,

are used

everywhere to provide reliable communications. Long CCTV

links in

security systems are now almost exclusively fiber. Even

millions of

cars use fiber (POF) for safety and

entertainment/communications

systems. If reliable communications are a must, fiber is

usually the

best choice.

-

- 1.2.

Technology often says go fiber

Fiber's advantages over copper result from the physics of

transmitting

with photons instead of electrons. In glass, optical

attenuation is

much less than the attenuation of electrical signals in

copper and much

less dependent on signal frequency. We all know that fiber

optic

transmission neither radiates RFI nor is susceptible to

interference,

making it the only choice for secure communications. Unlike

copper

wires that radiate signals capable of interfering with other

electronic

equipment, fiber is totally benign. Utility companies even

run power

lines with fibers imbedded in the wires for both

communications and

network management! The bandwidth/distance issue is what usually convinces the

user to

switch to fiber.

Where wireless is used is for mobile devices

connected on WiFi or cellular systems. Both generally depend on fiber

backbones for connectivity since wireless is not wireless except in the

final connection from antenna to the user's device.

-

- Read

more on fiber

vs

copper generally and in LANs or wireless in premises cabling systems.

Here is more information on fiber optics in the worldwide communications systems.

|

Learn

More

Here are some advanced ways to learn more about fiber

optics:

Fiber

U -

FOA's free online training program

FOA Guide To Fiber Optics

Freqently

Asked Questions (FAQs)

FOA Tech

Bulletins

|

- 2. Understanding Fiber

Optic Communications

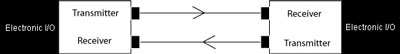

Fiber optic data links are the communications pathways between

devices. A

link is bidirectional, usually with signals transmitted in

two

directions on two different fibers. Using two fibers is

usually the

cheapest way, since the optical fiber itself is now about as

cheap as

kite string and fishing line! FTTH PONs - fiber to the home passive optical networks - use one

fiber in two

directions so it can use one PON coupler transmitting and

receiving for

lower system cost.

- The link connects electronic signals

from two

devices that need to communicate, just like a copper cable.

The link

has a transmitter that converts electronic signals from

communications

equipment to optics and a receiver that converts the signal

back to

electronics at the other end.

-

-

- Fiber

optic transceivers use LEDs or semiconductor lasers to

convert

electronic signals to optical signals. LEDs, similar to

those used

everywhere for indicators, except transmitting in the

infrared region

beyond human perception are used for slower links, up to

about 100

million bits per second (Mb/s), for example fast Ethernet

LANs. Faster

links use infrared semiconductor lasers because they have

more

bandwidth, up to tens of billions of bits per second (Gb/s).

Lasers

have more power, so they can also go longer lengths, as in

outside

plant applications such as long distance telecom or CATV.

As noted, transmitters use infrared light. Infrared light

has lower

loss in the fiber, allowing longer cable runs. Typically

multimode

glass fibers use light at 850 nm, referred to as "short

wavelength" and

singlemode fiber operates at 1310, 1470 or 1550 nm, called

"long

wavelength."

Safety Note: Since the light being transmitted through the optical fiber

is beyond

the range of human sight, you cannot look at the end of a

fiber and

tell if light is present. In fact, since some links carry

high power,

looking at the end of the fiber, especially with a

microscope which

concentrates all the light into the eye, can be dangerous.

Before

examining a fiber visually, always check with a power meter

to insure

no light is present unless you know the far end of the fiber

is

disconnected and use a microscope equipped with a laser

filter.

At the receiver end, a photodiode converts light into

electrical

current. Photodiodes must be matched to the transmitter

type,

wavelength, power level and bit rate as well as the fiber

size to

optimize performance. It's the receiver that ultimately

determines the

performance of the link, as it needs adequate power to

receive data

reliably. Receivers have a certain amount of internal noise

which can

interfere with reception if the signal is low, so the power

of the

optical signal at the receiver must be at a minimal level.

The power at the receiver is determined by the amount of

light coupled

into the fiber by the transmitter diminished by the loss in

the fiber

optic cable plant. The installer will test the cable plant

for loss

after construction, comparing it to a loss calculated from

typical

component values called the "loss budget." Transmitter power

can be

measured when the networking equipment is installed using a

patchcord

attached to the transmitter.

Networks adapt the generic fiber optic link described above

to a

specific network's needs. An Ethernet link will be optimized

for the

bitrate and protocol of the version of Ethernet to be used,

for example

Gigabit Ethernet. Video links may be analog or digital,

depending on

the camera, and may include camera controls in one direction

and video

in the other. Industrial links may be based on RS-232 or

RS-422

protocols.

Most computer or telecommunications networks have adopted

standards for

fiber optic transmission as well as copper wiring and

wireless.

However, sometimes the user has equipment with copper

interfaces but

wants to use fiber. Then they can use fiber optic media

converters,

which do exactly what their name suggests. Media converters

will

convert from one media to another, typically UTP copper to

optical

fiber, coax to optical fiber or multimode to singlemode

fiber. Media

converters are like transmitters and receivers in that they

must be

specified for specific network applications to insure the

proper

operation in that application.

Since so many link types exist, it is impossible to

generalize on fiber

optic link characteristics, but there

is a

table in the FOA website detailing most standard networks.

When designing or installing fiber optic cabling, the

contractor can

either design to cabling standards, which allows use with

any network

or communications system designed for those standards, or

for a

specific network, which may allow optimizing the cable

plant. If the

actual network to use the fiber optic cabling is not known,

the best

plan is to design, install and the test cable plant based on

standardized

fiber

optic component specifications rather than any

specific

network needs.

|

|

References

Whatever you want to know about

fiber, you can probably find it on

The FOA

Online Reference Guide To Fiber Optics

The

FOA Reference Guide To Fiber Optics (print version)

The

FOA Reference Guide to Premises Cabling (print version)

The

FOA Reference Guide To Outside Plant Fiber Optics (print

version)

- Typical

indoor fiber optic cables:

- zipcord,

distribution, loose tube and breakout (from top)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

|

3.

Checklist For Users Of Fiber Optic Communications Products

This is intended as an overview and installation checklist for

all

managers and engineers on the overall process of designing,

installing

and operating a fiber optic communications system. Fiber

optics offers

major advantages for communications systems including

security,

distance and bandwidth. Proper application of fiber optic

technology

will lead to highly reliable systems. But the user must choose

the

proper products, design and install an appropriate cable

plant, and

make sure components are tested, all following appropriate

industry

standards. This guide is designed to provide the information

necessary

to ensure proper installation and usage of fiber optic

systems. As

references, we will use:

The

FOA Online Reference Guide To Fiber Optics

The

FOA Reference Guide To Fiber Optics (print version)

The FOA Reference Guide to Premises

Cabling (print version)

The FOA Reference Guide To Fiber Optic Network Design

The NECA/FOA 301 Fiber Optic Installation Standard

Note

that these documents refer to other more detailed

documents such as TIA or ISO standards.

While

this document is primarily focused on the design,

installation and

maintenance of fiber optic cable plants, most end users will

be

interested in costs, so the FOA has a separate document on estimation.

3.1.

Overview of Fiber Optic Network Design and Installation

(Download

the comprehensive FOA Tech Bulletin on Designing

Fiber

Optic Networks. PDF 1.3 MB) or get a copy of the The FOA Reference Guide To Fiber Optic Network Design

3.1.1.

Select a communications system, link, module or converter that fits the data

format

you plan to transmit.

The first step is to choose the type of system needed. Fiber

optic

communications products exist for almost every type of

communications

system, from high speed telephone and CATV systems to simple

low speed

RS-232 or relay closure links. Many are media converters from

standard

electrical interfaces like Ethernet that have various options

on data

rates. Some are proprietary links for specialty equipment used

for

utility monitoring, industrial control, video surveillance,

etc.

3.1.2.

Select a fiber optic product that is specified to work over

the range

of your application. Note the type of fiber and other

components such

as connectors required for this product.

a. Consider the range of the link as that affects the type of

fiber and

transceivers needed.

b. Short links use multimode fiber and LED sources, while

longer links

use lasers and singlemode fibers.

c. Most fiber optic communications products offer several

versions that

cover different ranges.

d. Alternately, if you already have fiber optic cable plant

installed,

select a product that will operate over your fiber optic cable

plant,

considering both fiber type and distance.

3.1.3.

Select a fiber optic cable type appropriate for the

application.

a. Determine the working environment of the fiber optic cable

plant.

Some applications are in office environments, some on factory

floors,

above ceilings and some are outdoors.

b. Outdoors, some cables are installed aerially, either lashed

to a

messenger or self-supporting, some are buried directly or in

conduit

and some must run under water.

c. All outdoor cables require protection from water entry and

any other

environmental factors particular to the installation.

d. Each application puts requirements on the cable design that

should

be discussed with cable manufacturers who can recommend cable

types

appropriate for that application.

e. Not all manufacturers make the same type of cable, so

talking to

several vendors may provide options in cables that affect

price or

performance.

f. Consider installing several extra fibers in case any are

damaged in

installation or if additional fibers are needed for future

expansion.

(In fact, for critical applications, it may be advisable to

install a

complete backup link and/or redundant fiber optic cable plant

run in a

different route.)

g. Often singlemode fibers are added to multimode cables

(called a

hybrid cable) in case future networks need higher bandwidth.

h. At this stage, also decide on the installation hardware

needed, such

as conduit or innerduct for buried cables and hangers or

lashing for

aerial cables.

3.1.4.

Plan ahead on splicing requirements.

a. Long lengths of cables may need to be spliced, as fiber

optic cable

is rarely made in lengths longer than several kilometers due

to weight

and pulling friction considerations.

b. If fibers need splicing, determine how to splice the fibers

(fusion

or mechanical) and what kind of hardware like splice closures

are

appropriate for the application.

3.1.5.

Choose connectors of a style and termination type

appropriately for the

application.

a. Cables will need terminations to interface with the

communications

products.

b. Connectors need to be chosen appropriately or patchcords

with one

end terminated with connectors compatible with the

communications

products will be needed.

c. Fiber optic connectors have several termination methods,

some using

adhesives and polishing, some using splicing, which have

tradeoffs in

performance.

d. Discuss connectors with both manufacturers and installers

before

making this choice.

3.1.6.

Ensure the calculated link loss is substantially less than the

link

margin of the communications products.

a. Calculate the power/loss

budget for the link.

b. Using typical component specifications and the design of

the cable

plant (type of fiber, length, transceiver wavelength, number

of

connectors and splices) you can calculate the approximate

optical

loss of the cable plant

c. Compare it to the link margin for the communications

products you

have chosen.

d. Discuss potential margin problems with communications

equipment

vendors.

3.2.

Install the cable plant.

a. Using the design developed in this process, install the

cable plant.

b. Some users learn to install and maintain the fiber optic

cable plant

themselves, while others use contractors.

c. Installers or contractors should be trained and experienced

in the

installation type being done, have references for previous

work and be certified

by independent organizations like The Fiber Optic Association.

d. Follow the guidelines in the NECA 301-2004 Standard For

Installing

and Testing Fiber Optic Cables, available from The National

Electrical

Contractors Association.

e. Do not discard excess cable from the installation, but

store it for

future needs in restoration if the cable plant is damaged.

3.3.

Test the cable plant for end-to-end optical loss.

a. Test

the cable plant for optical loss according to industry

standards. Most cable plants are tested according to standards

TIA/EIA-526-14 for multimode fibers and TIA/EIA-526-7 for

singlemode

fibers using Method B, with a one cable reference for 0dB

loss. Calculate

the

approximate loss expected before you begin testing.

b. Longer cables with splices should also be tested with an

OTDR to

verify splice quality.

c. Cables installed aerially or in areas of likely stress can

also be

tested with the OTDR to verify installation quality.

d. Troubleshoot

any fibers that are high loss and correct the problem.

3.4.

Install the communications products and test their operation.

a. After the cable plant is tested and known good, install the

fiber

optic communications equipment and test its operation.

b. Use any self-testing options to check operation, use BERT

(bit-error

rate test) equipment or transmit known data and look for

errors.

c. Once a network is operating properly, it should require no

maintenance in fact, attempted maintenance on premises

systems by

un-qualified personnel is often a cause of damage so it is

best to

lock fiber optic component enclosures to reduce unauthorized

entry - a

requirement for class 4 (high power)lasers.

d. Outside plant networks may need frequent visual inspection

just to

find damage or potential damage.

3.5.

Document the fiber optic network.

a. Perhaps the most important part of any installation is the

final

documentation.

b. Accurate and complete documentation is invaluable in

upgrading,

troubleshooting or restoring a network. (Download the FOA Tech

Bulleting "Fiber

Optic

Restoration" PDF, 90 kB) Documentation should include

identification of all components, the paths of each cable,

types of

cable (and where the excess is stored for restoration), cable

section

lengths, locations of splices or terminations and the optical

loss of

each fiber measured at installation.

c. If OTDR traces are taken, those should be stored with the

documentation.

d. Copies of all documentation should be kept at each end of

the link

and backups stored in a safe place.

|

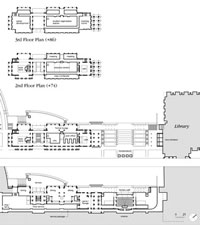

Documentation

begins with a good blueprint.

|

- 4.

Important Considerations in Fiber Optic Installation

Fiber optics offers major advantages for communications

systems

including security, distance and bandwidth. Proper

application of fiber

optic technology will lead to highly reliable systems. That

means the

user must install an appropriate cable plant and test every

component,

all following appropriate industry standards. This guide is

designed to

provide to those directly involved in planning and

installing the fiber

optic network the information necessary to ensure proper

installation

and usage of fiber optic systems.

-

- Notes:

- Every project needs "paperwork" to define the

project for both the user and the contractor. See the FOA

page on Paperwork for a rundown of the important

documents and what they mean.

- This list only concerns

itself with the project steps unique to fiber

optic systems, but many OSP applications require obtaining

permits,

easements or rights-of-way. That is beyond the scope of

this document!

-

- 4.1.

Do a complete design before beginning cable plant

installation. (FOTN,

Chapter 9 and NECA-301)

a. Establish criteria for the install, based on the

communications

paths required

b. Know how many fibers of what types are needed add

extras for

repairs or growth

c. Determine hardware requirements: connectors, splices,

patch panels,

closures, etc.

d. Plot the cable route and determine cable lengths

e. Show how installed (premises, buried, conduit, innerduct,

underwater, pole locations for aerial, etc.)

f. Mark termination and splice points

g. Attach data from link loss budget and use it as a guide

for testing

h. Don't try to build a marginal design allow for

"Murphy's Law"

i. Follow the NECA 301-2004 Standard For Installing and

Testing Fiber

Optic Cables in design and installation

j. At the same time, design the facilities for the

communications

equipment, including locations, allowing for adequate

spaces, power and

grounding and HVAC as needed

k. Make complete lists of what components and hardware are

needed and

where they are to be used

-

- 4.2.

Work with vendors on component specs to get best quality and

price.

a. Vendors usually have suggestions on components like

cables or

hardware that can facilitate design and implementation, but

always get

several opinions and compare their suggestions to what you

understand

you need .

b. Consider options like pre-terminated cables or air-blown

fiber for

short indoor cable runs

c. Remember to plan for purchasing overages on components to

cover

extra cable for restoration or extra connectors necessary

due to yields

in termination

d. Be careful of industry or manufacturer "jargon" as not

everyone uses

the same term in fiber optics

- e.

Once you have a design and component pricing, you can do a

complete project

cost

estimate.

-

- 4.3.

Have all components available before beginning installation

so crews

may complete the installation promptly and properly.

a. Inventory everything received

b. Check for shipping damage

c. Store in a safe, dry place until used

d. Separate as needed for each work site

e. While at the job site, consider using guards if

components are left

onsite overnight

-

- 4.4.

Use only trained, qualified installers, preferably

FOA-certified.

a. Installing fiber optics is not difficult, but has special

issues

familiar to those with experience

b. Make sure the installers are experienced in the type of

installation

you are planning, as installers often specialize in aerial,

underwater,

or even singlemode installation

c. Look for FOA

CFOT certification (www.thefoa.org) and good

references from

similar installations

d. Review the design with the installer to familiarize them

with the

job and see if they have advice on how to make it easier or

better but

use your judgement regarding any changes suggested.

-

- 4.5.

Review safety

issues and establish rules for the installation.

a. All installers and supervisors should be briefed on

safety rules

b. Ensure that you have copies of the documentation

regarding your

contractors bonding, insurance, workers compensation, OSHA

certificates

etc.

c. Use NECA/FOA 301 Standard, Section 3 plus any applicable

OSHA or

other regulations

-

- 4.6.

Install the cable plant.

a. NECA/FOA 301, Section 5.4 offers good guidelines for

installation

b. Watch for proper handling to prevent cable damage,

especially cable

tension and bend radius

c. Long lengths (>200m) can be tested by an experienced

technician with an OTDR after installation but before

splicing or

termination if there is any question about potential damage

during

installation. Remember OTDR testing is optional, but every

link

requires insertion loss testing with a meter and source.

d. Install the hardware: NECA 301, Section 5.5

e. Splice as needed: NECA 301, Section 6.3, generally use

fusion

splicing in outside plant and singlemode applications,

mechanical

splices limited to premises multimode cables

f. Terminate ends: NECA 301, Section 6.2, generally

multimode

connectors will be installed on the cables directly while

singlemode

connectors will use pre-terminated pigtails to reduce loss

and back

reflection which are both important to laser transceivers

used with

singlemode fiber, especially in short links (~<2 km)

g. All splices and terminations should be placed in

appropriate

hardware for protection

h. Remember to clean

all

connectors properly and keep dust caps on all

connectors

i. All fiber optic cables should be color-coded by jacket

colors

and/or marked with orange or yellow tags or whatever color

is

designated for your cable plant to identify it as fiber

optic cable.

j. Carefully mark all cables and connections for

identification in a

manner consistent with the company documentation processes.

k. Dust caps from the connectors and couplings terminated in

the

enclosure belong to that enclosure and should be put in a

small plastic

bag and taped inside the cabinet for future use.

-

- 4.7.

Test and troubleshoot the cable plant. (NECA-301,

Sec 7, 4

Ways To Test An Installed Cable Plant) and Troubleshooting

fiber optic

cable plants and communcations systems, Testing

FAQs )

- a.

All cable plants must be tested for insertion

loss per industry standards (TIA/EIA-526-14 for

multimode,

TIA/EIA-526-7 for singlemode fibers) at the wavelength(s) to

be used

with the transmission systems chosen

b. Insertion loss must be less than allowable link loss

margin for the

communications equipment being used on the fibers

c. Longer cable plants, especially singlemode and those

using splices,

should be tested by an experienced technician with an OTDR

to verify

splice loss and confirm the cable was not damaged during

installation (

Understanding

OTDRs

, More

advice on using OTDRs properly.)

d. Remember to clean

all

connectors properly and keep dust caps on all

connectors

e. All test data should be recorded for cable plant

acceptance and

saved for future troubleshooting and restoration

-

- 4.8.

Install the communications systems.

a. Install all the active devices according to

manufacturer's

specifications and test for proper operation

b. If patchcords are used for connecting optical ports to

the cable

plant, use tested patchcords that are known to be in good

condition.

Patchcords must match

the

fiber in the cable plant being tested to prevent

excess

loss.

c. Clean

all connectors after removing dust caps and before

connecting

to transceivers or cable plant connectors

d. Using an optical power meter and good reference test

cable, test

transmitter power levels to ensure it is within

manufacturer's

specifications

e. Using an optical power meter, test receiver power levels

to insure

it is within manufacturer's specifications (you can use

these two

pieces of data to calculate the loss of the cable plant

under actual

use, which should correlate with insertion loss test data

using a test

source

f. If the power exceeds the receiver dynamic range and

overloads it,

reduce the power by using attenuators of a type recommended

by the

equipment manufacturer placed at the receiver, checking with

the

optical power meter to ensure the lower power level is in an

appropriate range

-

- 4.9.

Document the fiber optic network. (NECA-301, Sec 8)

a. Perhaps the most important part of any installation is

the

documentation. Good documentation is invaluable in

upgrading,

troubleshooting or restoring a network

b. Documentation should include:

i. Design data, e.g. CAD drawings and maps

ii. Component types and manufacturers

iii. The paths of each cable

iv. Types of cable (and where the excess is stored for

restoration)

v. Cable section lengths

vi. Locations of splices or terminations

vii. Calculated loss budget

viii. The optical loss of each fiber measured at

installation

ix. Fiber numbers/colors connected to each communications

device,

noting transmitter and receiver orientation

x. Spare fibers available for expansion or use to replaced

damaged

fibers

xi. Types of communications equipment

xii. Wavelength of transmission

xiii. Transmitter and receiver power for each transceiver

(and

attenuator values if used)

xiv. OTDR traces if taken

xv. Name and contact information for installers

c. Copies of the documentation should be kept at each end of

the link

and backups stored in a safe place.

-

- 4.10.

Fiber optic premises networks generally do not require

periodic

maintenance.

a. As long as the network is communicating as expected, no

maintenance

should be required and the network should not be touched

unless

communications equipment is moved, added or changed.

b. Attempts at inspection or maintenance are a major cause

of damage to

cables or connectors and getting dirt into components

c. Hardware should be lockable to prevent unauthorized entry

d. Outdoor installations, being more prone to mechanical and

environmental damage should be visually inspected for damage

as part of

a regularly scheduled preventative maintenance program.

-

-

-

- Ask us questions and

give us your feedback. Contact

the FOA.

- If you are planning a fiber optic

communications

system, download a free copy of the NECA-301

Standard

For Installing And Testing Fiber Optic Cables.

|

|

- References:

- The

Fiber Optic Association, Inc. (FOA), www.thefoa.org

The

FOA Online Reference Guide To Fiber Optics

|

| |

Note: This

information is

provided by The Fiber Optic Association, Inc. as a benefit to

those

interested in designing, manufacturing, selling, installing or

using

fiber optic communications systems or networks. It is intended

to be

used as a overview and guideline and in no way should be

considered to

be complete or comprehensive. These guidelines are strictly

the opinion

of the FOA and the reader is expected to use them as a basis

for

creating their own documentation, specifications, etc. The FOA

assumes

no liability for their use. |

| |

Sign Up For The

FOA

Email Newsletter |