Fiber

Optic Data Links

The

purpose of this document is to define a “fiber optic

datalink,” its purpose, design and performance. It is

intended to provide guidance for the designer of

datalinks or communications systems and the installer of

fiber optic systems who must verify the performance of

the datalink including the cable plant installed for its

operation.

Datalinks

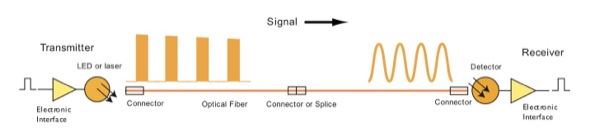

A fiber optic datalink is a communications subsystem

that connects inputs and outputs (I/O) from electronic

subsystems and transmits those signals over optical fiber.

In this function, a fiber optic datalink operates as an

alternative to copper cabling or a wireless subsystem. In

typical applications, a fiber optic datalink acts as a

communications medium attached to electronics on either

end that provide the other services necessary for

communications over the link. In the OSI (Open Systems

Interconnection) Network Model, the datalink is basically

the first layer, called the Physical Layer or PHY.

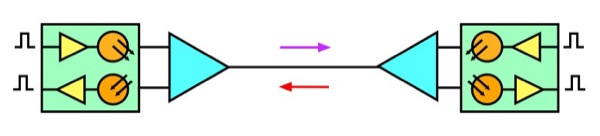

A

fiber optic datalink consists of fiber optic transceivers

or individual transmitters and receivers at either end

that transmit over optical fibers.

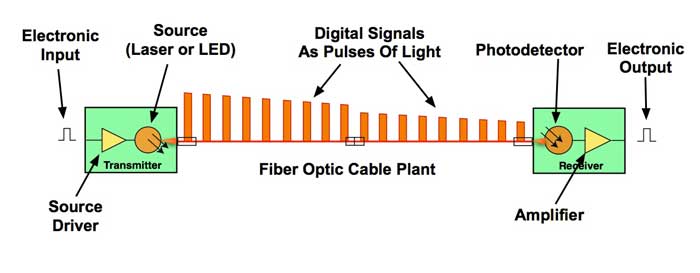

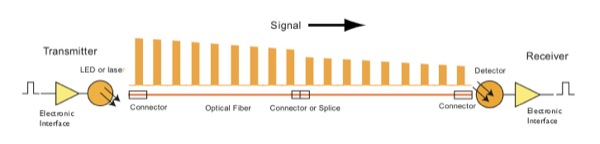

In operation, the fiber optic datalink gets an electrical

pulse input from an electronic system. In the transmitter,

a source driver sends current through a source, typically

a laser but sometimes a LED, which creates a pulse of

light. The pulse of light from the source is coupled into

an optical fiber that is part of a fiber optic cable

plant.

The pulse travels down the fiber where it is attenuated by

the fiber and suffers loss from fiber joints created by

splices or connections. At the receiver, the light pulse

is converted to an electrical pulse by a photodetector,

amplified by the receiver circuitry and converted to an

electrical pulse compatible with the communications

equipment it connects.

Signals and Protocols

Fiber optic datalinks may transmit signals that are

either analog or digital and of many different, usually

standardized, protocols, depending on the communications

system(s) it supports. Datalinks may be protocol

transparent but may also include data encoding to provide

more robust data communications. Datalinks may be

specified by the application or standardized network (e.g.

Ethernet) they are intended to support or by the types and

bandwidth of signals they are designed to transmit.

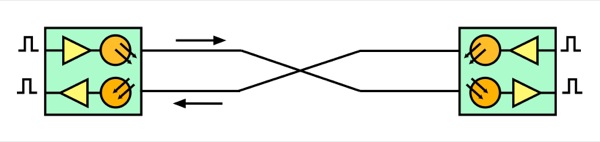

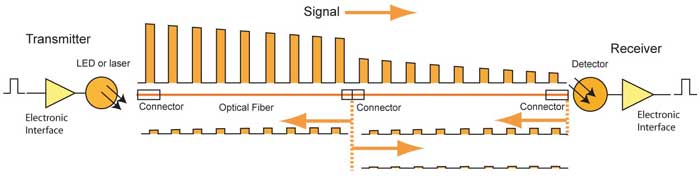

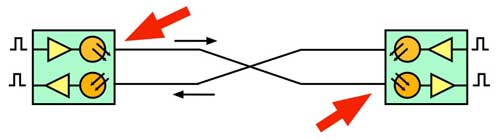

Components Of A Fiber Optic Datalink Using 2 Fibers For

Full Duplex Operation

The typical datalink transmits over two fibers for full

duplex links, one fiber in each direction. The fibers may

be of any type, multimode (graded index or step index) or

singlemode.

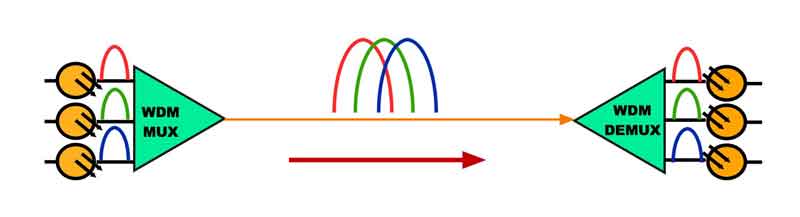

Wavelength division multiplexing allows sending multiple

signals over the same fiber simultaneously.

Some links may use wavelength-division multiplexing to

transmit bi-directionally over a single fiber as in FTTH

PONs passive optical networks or OLANs, optical LANs. Some

links may allow transmission at several wavelengths of

light simultaneously over a single fiber in each

direction, called wavelength-division

multiplexing.

Components

Of A Fiber Optic Datalink Using A Single Fiber

Extremely long cable plant lengths may require

regeneration using repeaters, essentially datalinks in

series. Optical

fiber amplifiers may be used as repeaters in long

singlemode systems. Singlemode systems using fiber

amplifiers and wavelength-division multiplexing may

require concern for nonlinear effects from high optical

power involved.

Analog

or Digital?

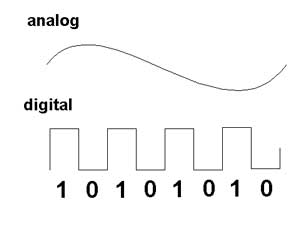

Analog

signals are continuously variable signals where the

information in the signal is contained in the amplitude

of the signal over time. Digital signals are sampled at

regular time intervals and the amplitude converted to

digital bytes so the information is a digital number.

Analog signals are the natural form of most data, but

are subject to degradation by noise in the transmission

system. As an analog signal is attenuated in a

cable, the signal to noise ratio becomes worse so the

quality of the signal degrades. Digital signals can be

transmitted long distances without degradation as

the signal is less sensitive to noise.

Fiber

optic datalinks can be either analog or digital in

nature, although most are digital. Both have some common

critical parameters and some major differences. For

both, the optical loss margin or power budget is most

important. This is determined by connecting the link up

with an adjustable attenuator in the cable plant and

varying the loss between transmitter and receiver until

one can generate the curve shown above. Analog datalinks

will be tested for signal to noise ratio to determine

link margin, while digital links use bit error rate as a

measure of performance. Both links require testing over

the full bandwidth specified for operation, but most

data links are now specified for a specific network

application, like AM CATV or RGB color monitors for

analog links and SONET, Ethernet or Fibre Channel for

digital links.

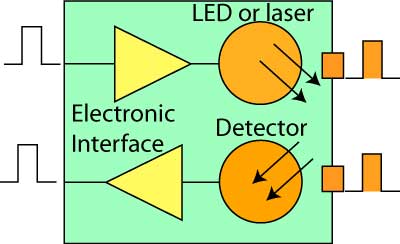

Transceiver

A

fiber optic transceiver used on each end of a link

includes a transmitter and receiver that convert

electrical signals to optical signals and vice versa for

transmission over optical fiber. Appropriate interfaces

are included in the datalink to mate with the electrical

and optical signals it connects with. These are

typically standardized electrical and fiber optic

connectors.

Fiber

optic transceiver block diagram

The transmitter consists of an electrical input and

signal conditioning circuitry to drive an optical

source, a light-emitting diode or laser that provides

the electrical to optical conversion and alignment

hardware for coupling of the optical signal into an

optical fiber for transmission.

The receiver consists of a detector that connects to the

optical fiber to accept an optical signal, convert the

optical signal that has been transmitted through the

optical fiber to an electrical signal and conditioning

circuitry that creates an electrical output compatible

with the communications system.

Transceivers are dedicated to one type of fiber

determined by the distance and bandwidth of the

communications being transmitted. Multimode fiber may be

used for shorter and/or slower datalinks while

singlemode fiber is used for longer links. The source in

the transceiver will also depend on the application.

LEDs are used for slower (<~100 Mb/s) multimode links

and VCSELs are used for faster multimode links.

Some standard networks have options for using singlemode

1310nm lasers on multimode fiber. There are currently

four types of multimode fiber used for datalinks,

designated OM1-4. OM-1 is a fiber with larger core (62.5

microns) used primarily in legacy systems with LEDs at

850 or 1300 nm wavelengths. Faster multimode links use

OM-2, OM-3 or OM-4 fiber with a 50 micron core,

generally the faster fibers designated OM-3 or OM-4

which are optimized for 850 nm VCSELs.

Singlemode

systems use lasers at 1310 or ~1550nm. 1310nm lasers are

used for shorter links. The longer wavelengths around

1550 nm are used for long links and those using

wavelength-division multiplexing. There are several

specialized singlemode fibers which are optimized for

special applications.

As

the use of links at 100Gb/s or more become common,

datalinks become more complex. Above about 25-50 Gb/s,

the average limit for direct modulation of typical laser

sources, amplitude modulation, wavelength division multiplexing, parallel

optics and coherent fiber optic systems are used. In

addition coherent systems can be more effective to

overcome dispersion in long links. Read

more about coherent fiber optic systems.

More

on fiber optic transceivers and their components

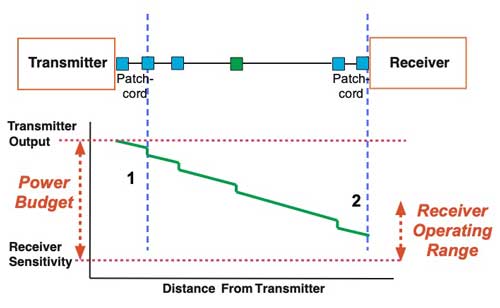

Power Budget

All

datalinks are limited by the power budget of the link.

The power budget is the difference between the output

power of the transmitter and the input power

requirements of the receiver. The receiver has an

operating range determined by the signal-to-noise ratio

(S/N) in the receiver. The S/N ratio is generally quoted

for analog links while the bit-error-rate (BER) is used

for digital links. BER is practically an inverse

function of S/N.

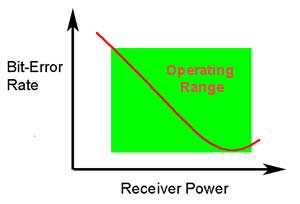

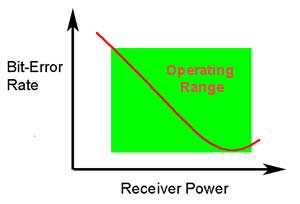

BER vs received optical power for a fiber optic

transceiver

The operating range of a data link will look like the

graph above. There must be a minimum power at the

receiver to provide an acceptable signal to noise ratio

(S/N) or Bit Error Rate (BER, which is inversely

proportional to S/N.) As the power increases, the BER or

S/N improves until the signal becomes so high it

overloads the receiver and receiver performance degrades

rapidly. If the receiver is overloaded, one can use attenuators

to reduce the power to an acceptable level.

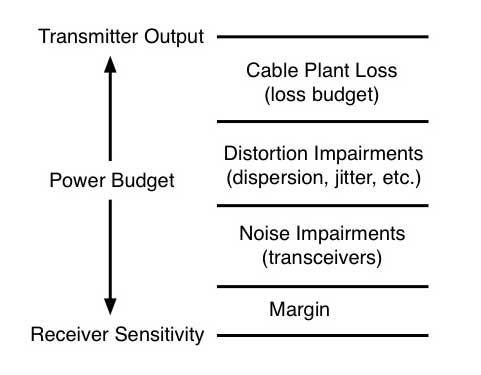

The power of the receiver is determined by the output

power of the transmitter diminished by the loss in the

cable plant primarily but other factors may affect power

budget performance. When the power budget is inadequate

for the loss in the cable plant, higher power

transmitters or more sensitive receivers or higher

bandwidth cable plant are required.

Contributions

to link power budget.

Link power budget

Transceivers may be components intended to be built into

electronic subsystems to create communications

equipment. Standalone transceivers may be sold as media

converters to convert signals from electrical on copper

cabling to fiber optics. Built-in transceivers are

generally powered by the communications equipment in

which they are installed. Media converters are powered

by separate sources of electrical power.

More on

power budgets and the similar "loss budget" which is

the estimate of fiber optic cable plant loss.

Fiber Optic Cable Plant

A

fiber optic datalink transmits signals as pulses or

varying light over optical fibers that are included in a

fiber optic cable plant. The permanently installed cable

plant consists of an optical fiber cable designed to

protect the fibers, which is installed, spliced and

terminated with proper hardware to mate with the

datalink transceivers. The cable plant must be selected

and installed to withstand the environment in which it

is installed. The cable plant is typically terminated at

outlets or patch panels near the communications

equipment. The installed cable plant is typically

connected to the transceivers by short patchcords.

The fiber optic cable plant must be compatible with the

performance parameters of the transceivers for the link

to operate properly. This includes types of fiber and

connectors, optical loss and bandwidth of the cable

plant. For the cable plant, a loss budget must be

calculated to estimate its loss and a power budget to

determine if the planned communications system will

operate over the cable plant.

Fiber polarity is important for design and

documentation. Since the transmitter must be connected

to the receiver for the link to operate, there must be a

crossover in the fiber pair at some point in the cable

plant. Generally, the permanent cable plant is installed

straight through, with fiber 1 connected to fiber 1 on

each end, and so forth. Since the link requires one

crossover, that is accomplished by a crossover patch

cord on one end of the link. The location of crossover

patchcords should be limited to one area, e.g. the main

equipment room, so all duplex patch cords at that

location are crossover cables while straight through

cables are used at all other locations.

Cable Plant Performance

Parameters

The

factors that determine the required performance

parameters for a fiber optic datalink are those that

define the communications signals to be carried on the

link (the data bitrate (digital transmission) or

bandwidth (analog transmission) at which the link

operates), the length of the link and the specifications

(bandwidth and optical loss) of the fiber optic cable

plant. These factors determine the types of transceivers

and cable plant components that must be chosen for a

communications system.

The two major factors of concern in link design and

testing after installation are the loss of the cable

plant and the bandwidth.

Cable

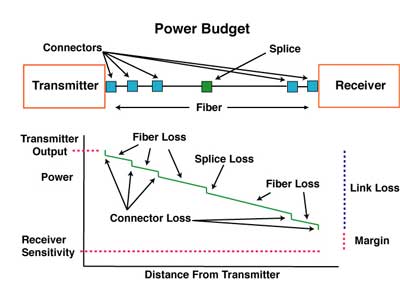

Plant Loss

The loss of the cable plant is determined by the summation

of the loss in the cable plant due to fiber attenuation,

splice loss and connector loss. In some cases the fiber

attenuation may be increased by improper installation of

the cable. As a signal travels down the fiber, the signal

will be attenuated by the optical fiber and reduced by the

loss in connectors and splices.

Loss of signal by attenuation in the cable plant

Loss Budgets

For

each cable plant designed, one must calculate a loss

budget. The loss budget estimates the loss of the fiber

in the cable plant by multiplying the length (km) by the

attenuation coefficient (dB/km), then adding the loss

from connectors and/or splices determined by the number

of connectors and/or splices times the estimated loss

each to get the total estimated loss of the cable plant.

The cable plant loss budget must be lower than the power

budget of the link transceivers (see below) for the link

to work properly.

Dispersion

Dispersion

or pulse spreading limits the bandwidth of the link.

Transceivers have some dispersion caused by the

limitations of the electronics and electro-optical

components but most of the dispersion comes from the

limited bandwidth of the fiber in the cable plant.

Dispersion of signal in the cable plant

Dispersion in multimode optical fiber occurs by modal

dispersion or chromatic dispersion. Modal dispersion is

caused by the different velocities of the various modes

being transmitted in the fiber. Chromatic dispersion is

caused by the different velocities of light at different

wavelengths.

Singlemode fiber also causes dispersion, but generally

only in very long links. Chromatic dispersion has the

same cause as multimode fiber, the differences in the

speed of light at different wavelengths. Singlemode

fiber may also suffer from polarization-mode dispersion

causes by the different speeds of polarized light in the

fibers.

The transceiver must be chosen to provide proper

performance for the communications system’s requirements

for bandwidth or bitrate and to provide an optical

transmitter output of sufficient power and receiver of

adequate sensitivity to operate over the optical loss

caused by the cable plant of the communications system.

The difference in the transmitter output and receiver

sensitivity defines the optical power budget of the

link.

The cable plant components, optical fiber, splices and

connectors, are chosen to allow sufficient distance and

bandwidth performance with the transceivers to meet the

communications system’s optical power budget

requirements. The power budget of the link defines the

maximum loss budget for the cable plant. The maximum

link length will be determined by the power budget and

loss budget for low bit rate links that will be derated

for dispersion for higher bandwidth links.

Most standardized communications systems will specify

the performance of the components including interfaces

to the electronic I/O and types of fiber supported for

various distances. Systems standards may also include

specifications for fiber optic connector type, primarily

at the transceiver. Most communications systems with

short links have options for both multimode and

singlemode fiber while longer links use only singlemode

fiber. All networks may provide guidance as to the types

or grades of fiber needed to support certain

applications.

Every manufacturer of datalinks components and systems

specifies their link for receiver sensitivity (perhaps a

minimum power required) and minimum power coupled into

the fiber from the source. Typical values for these

parameters are shown in the table below. In order for a

manufacturer or system designer to test them properly,

it is necessary to know the test conditions. For data

link components, that includes input data frequency or

bitrate and duty cycle, power supply voltages and the

type of fiber coupled to the source. For systems, it

will be the diagnostic software needed by the system.

Typical

Fiber optic link/system performance parameters

| Link

type |

Source/Fiber

Type |

Wave-

length

(nm)

|

Transmit

Power (dBm) |

Receiver

Sen- sitivity (dBm) |

Margin

(dB) |

| Telecom |

laser/SM |

1300/1550 |

+3 to -6 |

-30 to -45 |

30 to 40 |

|

DWDM |

1550 |

+20 to

0 |

-30 to -45 |

40 to 50 |

| Datacom |

LED/VCSEL |

850 |

-3 to -15 |

-15 to -30 |

3 to

25 |

|

LED/laser |

1300 |

-0 to -20 |

-15 to -30 |

10 to 25 |

| CATV(AM) |

laser/SM |

1300/1550 |

+10 to 0 |

0 to -10 |

10 to 20 |

Within

the world of data communications links and networks,

there are many vendor-specific fiber optic systems, but

there are also a number of industry standard networks

such as Ethernet which have fiber optic standards. These

networks have agreed upon specifications common to all

manufacturers' products to insure interoperability. This

page in FOA Tech Topics shows a summary of

specifications for many of these systems.

Reflectance

Reflectance refers to the light reflected at a connection

or mechanical splice. Some light is reflected back toward

the source and may sometimes be reflected many times in

short cables, creating a source of noise from the fiber

optic cable plant. If the source is a laser in a

singlemode link, the light reflected from a connection

near the source can cause problems with the laser also. In

short singlemode links it is common to use "APC"

connectors (angled physical contact connectors) that

practically eliminate reflections.

Reflectance in a data link

Testing

Datalink Performance

Design and Manufacturing

During

the design and manufacturing process, datalinks are

tested for proper transmission over specified distances

for optical loss and bandwidth. Loss testing is done by

transmitting through a variable optical attenuator over

short lengths of fiber (to eliminate dispersion effects)

to create a diagram of bit error rate (BER) vs received

optical power (or signal-to-noise ratio, SNR, the

inverse of BER) which shows the range of optical loss

the transmitter/receiver pair can operate over.

BER vs received optical power

In the drawing above, the link has a lower BER as the

optical power increases since the S/N ratio improves.

This generally continues until the receiver power

becomes too high and the receiver overloads. If the

transmitter power is high and the cable plant loss low,

it is possible in some systems to overload the receiver.

In that case an optical attenuator should be used at the

receiver to lower power to acceptable levels.

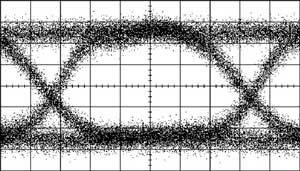

Bandwidth testing is generally done by bit error rate

testing or examining “eye diagrams” of signals for

dispersion. The most common way to overcome dispersion

effects is to increase optical power at the receiver by

reducing the length of the cable plant and/or lowering

the loss budget of the cable plant.

Bandwidth Eye diagram

This type of testing will provide specifications for the

datalink as to the types of fiber required and the loss

budget of the link. It is those specifications that will

determine the use of the datalink in a communications

system design and what performance parameters will need

testing after installation.

Installed Datalink

Testing

Testing

installed datalinks includes testing the cable plant

first then testing the operation of the datalink

transceivers over the cable plant. The cable plant will

be tested after installation to ensure the installation

was done properly before the communications system is

installed and tested.

Multimode cable plants are rarely tested for bandwidth

but require testing for optical loss (called insertion

loss.)

Short singlemode cable plants are also tested for loss

only, but long distance high bitrate singlemode systems

may also require testing the cable plant for bandwidth,

e.g. chromatic dispersion and polarization mode

dispersion. Short links may also have problems with

reflectance from connectors, so special non-reflective

APC style connectors are usually specified since

reflectance testing can be difficult.

Testing the operation of the transceivers with the cable

plant includes optical power testing of the output of

the transmitter and the receiver input power compared to

specifications for the link.

Power

testing of datalink.

After the datalink or communications system is

installed, testing the BER or SNR of the complete

communications link may be done to confirm that the link

is operating properly.

FOA

Standards for testing cable plant loss and optical

power can be used to properly specify test

requirements.

Test Your Comprehension

After you study this page and "More

on fiber optic transceivers and their components" you

should test your comprehension here.

Table

of Contents: The FOA Reference Guide To Fiber Optics