Fiber Optic Cable And Connector Color

Codes

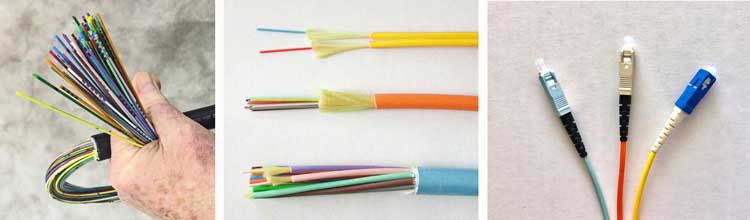

Color codes are used in fiber optics to

identify fibers, cables and connectors. In the photos above, on the left

is a 1728 fiber cable with color coded buffer tubes, in the center are

(from the top) singlemode zipcord cable used for patchcords with each

fiber color coded, and on the right, a yellow SM cable with a blue

connector indicating a PC connector, an orange cable with beige

connector indicating 62.5/125 multimode fiber and an acqua cable and

connector that identifies laser-optimized 50/125 fiber.

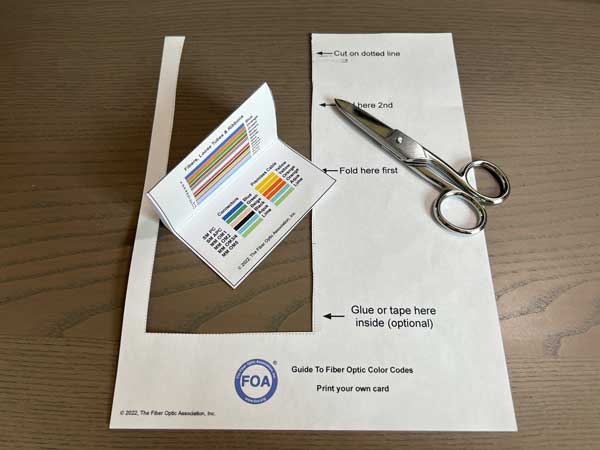

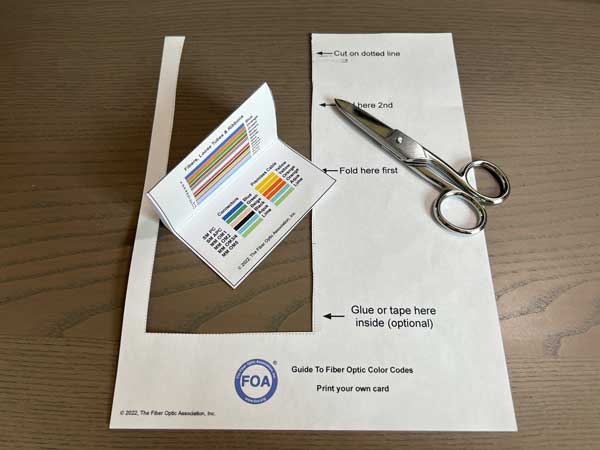

Download this PDF, print it on a color printer and cut it out to make your own pocket FOA Guide To Fiber Optic Color Codes.

or download this Color Code PDF to keep on your smartphone, tablet or computer.

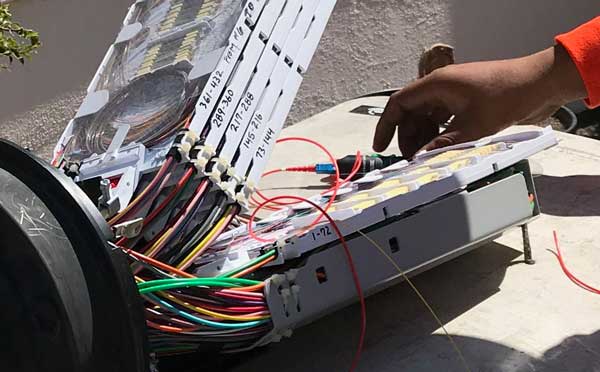

Here is another example with an OSP splice closure where a 432 fiber cable is broken out to two separate cables.

Each splice tray has 72 splices so the arrangement of the colored buffer tubes and the colored fibers is used to keep all the connections correct.

Splicing ribbon cable is easier, since the ribbons are arranged in the standard way shown below so one must only match up the ribbons.

Here's how the spliced ribbons look:

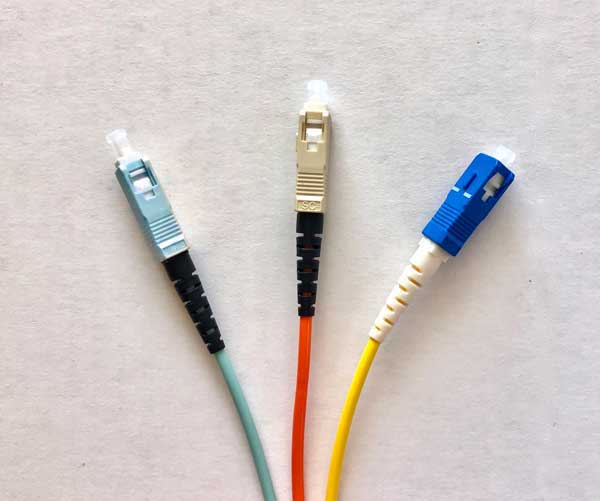

Patchcords used with patch panels can easily get mixed up. Standards use color codes for fiber and connector types to make it easy to find the right patchcord.

Color codes make

it easy to identify these patchcords which all have SC connectors: aqua

cable and connector indicate 50/125 laser optimized fiber on the

cable to the left. In the center, orange cable means multimode fiber and

the beige connector indicates 62.5/125 fiber. On the right, the yellow

patchcord indicates singlemode fiber and the blue connector means it is

a regular PC polished connector, If it were an APC connector, it would

be green.

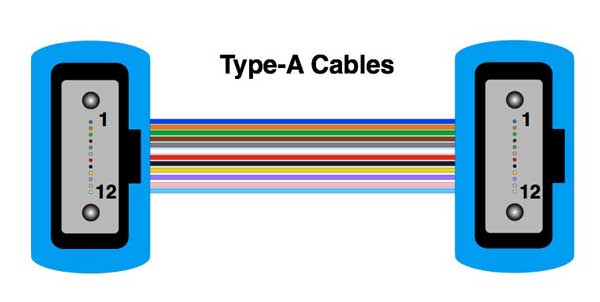

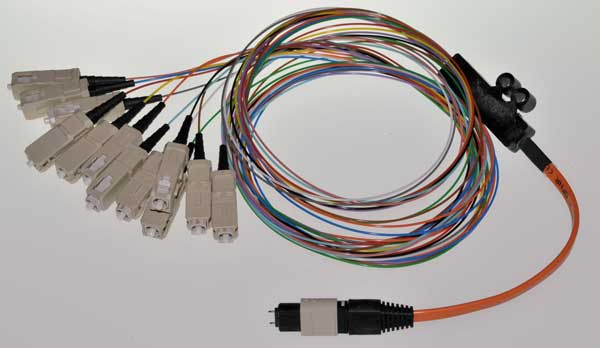

Breakout cables for MPO cable plants need color codes to keep track of the individual connector fibers.

The beige

connectors indicate this is 62.5/125 fibers. Colot codes on the 900

micron tight buffer fiber identifies fibers 1-12.

There is a color code standard in TIA, TIA-598 that addresses fiber optic color codes, which most manufacturers adopt and reference, although there are many exceptions based on customer requirements or preferences. Here is what TIA-598 recommends:

Cable Jacket Colors

Colored outer jackets and/or print may be

used on Premises Distribution Cable, Premises Interconnect Cable or

Interconnect Cord, or Premises Breakout Cable to identify the

classification and fiber sizes of the fiber. (Outdoor cables are

generally black for protection against UV light and markings are printed

on the cable.)

When colored jackets are used to identify the type of fiber in cable containing only one fiber type, the colors shall be as indicated in Table 3. Other colors may be used providing that the print on the outer jacket identifies fiber classifications. Such colors should be as agreed upon between manufacturer and user.

Unless otherwise specified, the outer jacket

of premises cable containing more than one fiber type shall use a

printed legend to identify the quantities and types of fibers within the

cable. Table 3 shows the preferred nomenclature for the various fiber

types, for example "12 Fiber, 8 x 50/125, 4 x SM." Some manufacturers

use black as the jacket color for hybrid or composite cables.

When the print on the outer jacket of

premises cable is used to identify the types and classifications of the

fiber, the nomenclature of Table 3 is preferred for the various fiber

types. Distinctive print characters for other fiber types may be

considered for addition to Table 3 at some future date.

| Fiber Type | Color Code | ||

| . | Non-military Applications(3) | Military Applications | Suggested Print Nomenclature |

| Multimode (50/125) (OM2) | Orange | Orange | OM2, 50/125 |

| Multimode (50/125) (850 nm Laser-optimized) (OM3, OM4) | Aqua | Undefined | OM3 or OM4, 850 LO 50 /125 |

| Multimode (50/125) (850 nm Laser-optimized) (OM5) | Lime Green | Undefined | OM5 |

| Multimode (62.5/125) (OM1) | Orange | Slate | OM1, 62.5/125 |

| Multimode (100/140) | Orange | Green | 100/140 |

| Single-mode (OS1, OS1a, OS2) | Yellow | Yellow | OS1, OS1a, OS2, SM/NZDS, SM |

| Polarization Maintaining Single-mode | Blue | Undefined | Undefined (2) |

NOTES:

1) Natural jackets with colored tracers may be used instead of

solid-color jackets.

2) Because of the limited number of applications for these fibers, print

nomenclature are to be agreed upon between manufacturer and enduser

3) Other colors may be used providing that the print on the outer

jacket identifies fiber classifications per subclause 4.3.3.

4) For some Premises Cable functional types (e.g., plenum cables),

colored jacket material may not be available. Distinctive jacket colors

for other fiber types may be considered for addition to Table 3 at some

future date.

Users have been installing hybrid (MM+SM)

cables in the backbone for years. With the premises fiber optic cabling

now including several varieties of 50/125 fiber, 62.5/125 and singlemode

fibers, managing the cable plant is more difficult. We have already seen

instances of users and installers being confused and getting bad test

results, as well as having problems with networks operating when

connected over the wrong fiber type. Connector color codes may be used

to identify fiber type also. If unsure about the fiber, core size can be

determined by examining the connector ferrule with a fiber optic

inspection microscope while illuminating the fiber with a white light

(flashlight).

| Fiber

type |

Connector

Body |

Strain

Relief/ Mating Adapter |

| 62.5/125 |

Beige |

Beige |

| 50/125 OM2 |

Black |

Black |

| 50/125

laser optimized (OM3, OM4) |

Aqua |

Aqua |

| OM5

wideband fiber |

Lime |

Lime |

| Singlemode |

Blue |

Blue |

| Singlemode

APC |

Green |

Green |

Fiber Color Codes

Inside the cable or inside each tube in a loose tube cable, individual

fibers will be color coded for identification. Fibers follow the

convention created for telephone wires except fibers are identified

individually, not in pairs.

Buffer tubes follow the same color sequence

up to 12 tubes, then tubes 13-24 will repeat the colors with a black

stripe (black will have a yellow stripe), tubes 25-36 will follow the

same color with an orange stripe, 37-48 use a green stripe, following

the same color code sequence for the stripe. Tubes containing more than

12 fibers will use binder tape to separate fibers into groups. Ribbon

cables follow this color sequence also.

For splicing, like color fibers are

generally spliced to ensure continuity of color codes throughout a cable

run.

| Fiber Number | Color |

| 1 | Blue |

| 2 | Orange |

| 3 | Green |

| 4 | Brown |

| 5 | Slate |

| 6 | White |

| 7 | Red |

| 8 | Black |

| 9 | Yellow |

| 10 | Violet |

| 11 | Rose |

| 12 | Aqua |

There is a publicly

available document that defines the twelve TIA/EIA colors for fiber

conductors: http://munsell.com/color-blog/color-codingchart-wire-color-coding/

Note: Fibers 13-16 are specified for 16 fiber MPO connectors as follows: 13: Olive, 14: Magenta, 15: Tan, 16: Lime.

| Fiber Number | Color |

| 1 | Blue |

| 2 | Orange |

| 3 | Green |

| 4 | Brown |

| 5 | Slate |

| 6 | White |

| 7 | Red |

| 8 | Black |

| 9 | Yellow |

| 10 | Violet |

| 11 | Rose |

| 12 | Aqua |

| 13 |

Olive |

| 14 |

Magenta |

| 15 |

Tan |

| 16 |

Lime |

There is a

publicly available document that defines the twelve TIA/EIA colors for

fiber conductors: http://munsell.com/color-blog/color-codingchart-wire-color-coding/

Download this PDF, print it on a color printer and cut it out to make your own pocket FOA Guide To Fiber Optic Color Codes.

Or download this PDF for a Fiber Optic Color Code Guide you can save on your smartphone, tablet or PC for quick reference.

And if you work with copper cabling, here is a UTP Color Code Guide PDF.

(C) 2022, The

Fiber Optic Association, Inc.

Return To The FOA Home Page

Return To FOA Guide