Fiber To The Home

Network Design

There is really no way to generalize on the design process

for fiber to the home (FTTH) networks - or any fiber optic

network for that matter - since every system is unique. If

you are familiar with FOA's other design materials, you

know we don't give you formulas or outlines to follow.

Rather than telling you how to design a FTTH network, we

will illustrate some of the different network

architectures, construction methods, etc. possible, then

offer options that may work for your network and stimulate

your design processes.

If you are new to fiber optic network

design, we recommend you study the

design pages on the FOA Guide, read the FOA textbook

Reference

Guide to Fiber Optic Network Design, and

perhaps take the

Fiber Optic Network Design self-study course on

Fiber U to prepare yourself for designing your own

network. That will help you understand how to design and

install systems most efficiently before beginning your own

project. And, of course this

complete series on FTTH here on the FOA Guide.

The best way to understand the options

in FTTH network design is to consider several very

different types of networks which differ by subscriber

density, geography and technical issues which affect the

design decisions that must be made.

- Urban

- Suburban

- Multi-dwelling

Units

- Rural

Within each of these we will discuss design options that

have been proven successful in the real world. We will

look at how to design the architecture of the system as

well as the design of the cable plant itself, down to the

component level. We will also look at cost implications

and future upgrades. We'll try to illustrate the options

to help you understand them.

We begin with some important background material.

Jargon

PON (Passive

Optical Network)

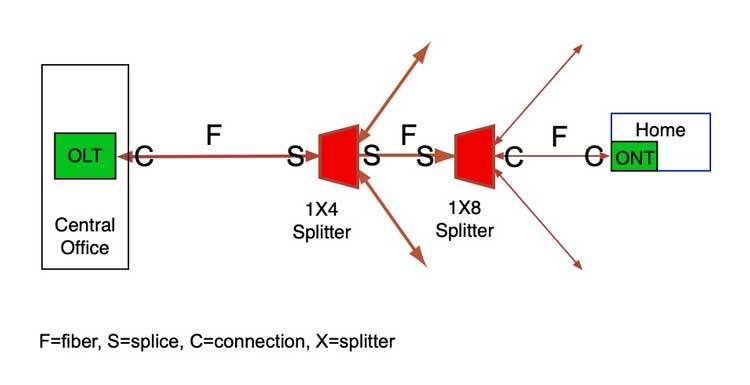

Most FTTH networks are based on passive optical

network architectures, simply because that's usually the

lowest cost way to design a FTTH network. There are other

architectures that may be preferable in some circumstances

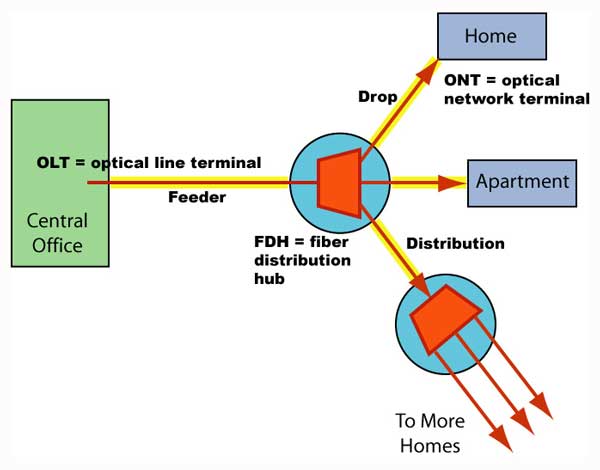

and we'll discuss those too. This drawing shows the

location of the hardware used in creating a typical PON

network. This drawing also defines the network jargon for

cables: a "feeder" cable extends from the OLT (optical

line terminal) in the CO (central office) to a FDH (fiber

distribution hub) where the PON (passive optical network)

splitter is housed. It then connects to "distribution"

cables that go out toward the subscriber location where

"drop" cables will be used to connect the final link to

the ONT (optical network terminal).

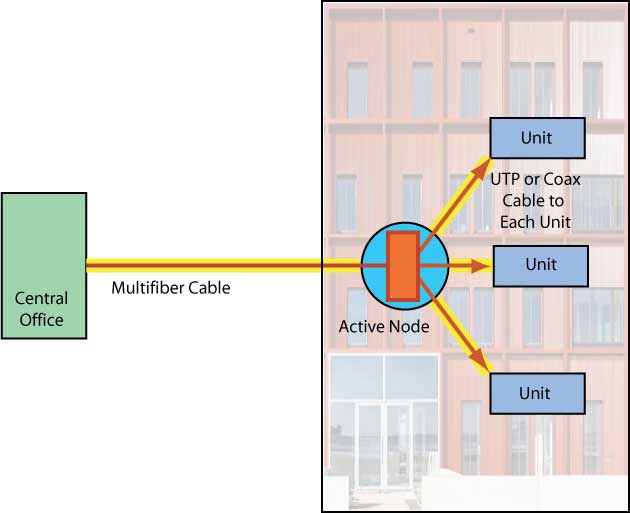

Active Star

An alternate to

a PON is an active star network, also called a

point-to-point (P2P) or "home run" system where each

subscriber has a dedicated fiber and Ethernet link to the

head end or central office. The main difference with

a PON is the amount of fiber required for the network,

especially if the service provider's switches are located

at the head end. Switches can be remote, closer to the

subscribers, but the switch requires power, a UPS and

perhaps even heat/AC, making that option much more

complex.

We will focus on PONs but mention

P2P and even some options for wireless or wireline for

drops.

Gig or 10Gig?

Standards for PONs give you an option

of gigabit or 10 gigabit networks. Technically what is

called gigabit (G for short) is regular GPON which offers

OLT ports at 2.5G downstream and 1.25G upstream, shared

among 32 (normal) or 64 (rare) users. Provisioning is

generally for 1G down and some lower value up on each OLT

port. If you don't understand the stochastic nature of

networks, you might assume that 32 users with 1Gb/s of

bandwidth have only about 30Mb/s (1Gb/s = 1000Mb/s, divide

by 32 = 31.25Mb/s). But that's not realistic. The full 1G

of bandwidth is available to all users who only use it a

fraction of the time, so their data is transferred at 1G

speeds. Average usage for most FTTH networks averages only

a few Mb/s, so 1G PONs are very effective.

But 10G PONs are available and like all

electronics, costs keep coming down, so they are being

considered for many networks. It is doubtful that any FTTH

network aimed

at consumer subscribers needs 10G, but some business

customers might. The GPON designers were clever, however,

making 10G use different wavelengths than 1G, so if you

build a 1G GPON network, you can upgrade at any time - say

to accommodate a network expansion aimed at businesses -

and run both networks simultaneously over the same cable

plant. Generally, we recommend building networks at 1G to

take advantage of the lower cost electronics, but knowing

that upgrades can be made simply and use the very same

cable plant.

Network

Architectures

PONs have options on architectures that can affect cost

and ease installation. One of the first decisions the

designer needs to make is where to locate splitters as

that will affect other hardware decisions like how many

fibers should cables have and what types of hardware to

use. To make that decision, one first needs to understand

the distribution of subscribers as location and density

are important for designing an efficient system. Here are

some options on design:

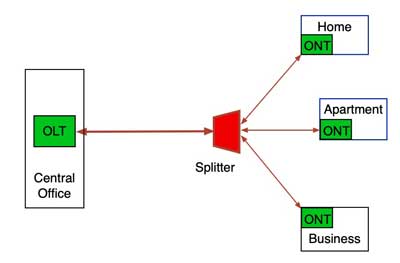

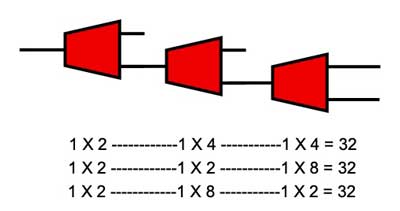

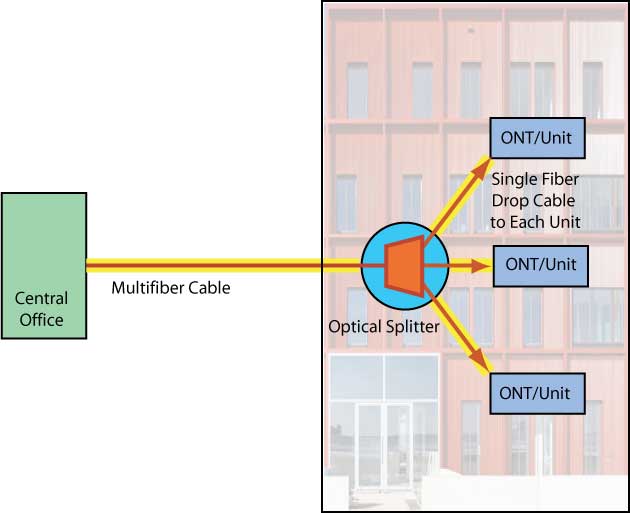

PONs work on the principle that

splitters allow one central port to communicate with 32 or

64 users over a single fiber to the splitter and then a

single fiber to each user. Typical PON architectures are

shown like this:

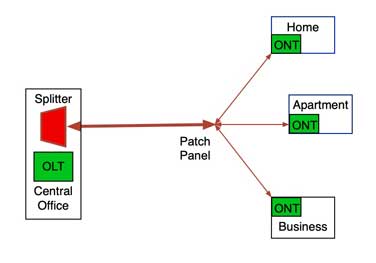

In reality, there is a lot of

flexibility in the location of splitters. For example,

some dense urban or suburban networks move the splitter

into the Central Office (CO - a traditional telecom term)

or Head End (the CATV term) and run a fiber to every user

like this:

While this option requires more fiber,

large fiber count cables are readily available and fiber

cost is low, so the incremental cost to use more fibers in

a cable is reasonable. If the splitter is in the CO, the

OLT can be utilized more efficiently since each port can

support 32 or 64 users from any location in the service

area. If splitters are moved closer to the users, some

ports must be left open for future expansion, meaning that

OLT port will support fewer than the maximum number of

users - about 24 ports being used seems average, with 8

ports being open for future subscribers. With a central

splitter and fiber to each user configuration, there is

flexibility to use each OLT port more efficiently, adding

new OLT ports only when needed, and when every customer

has a dedicated fiber, the CO can even support several

ISPs (Internet Service Providers) by simply patching the

user to their chosen ISP.

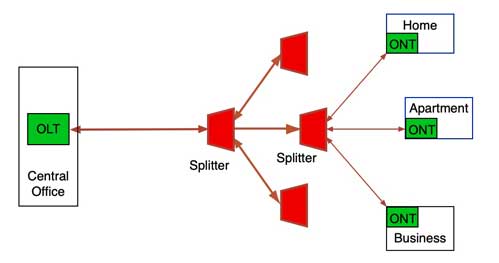

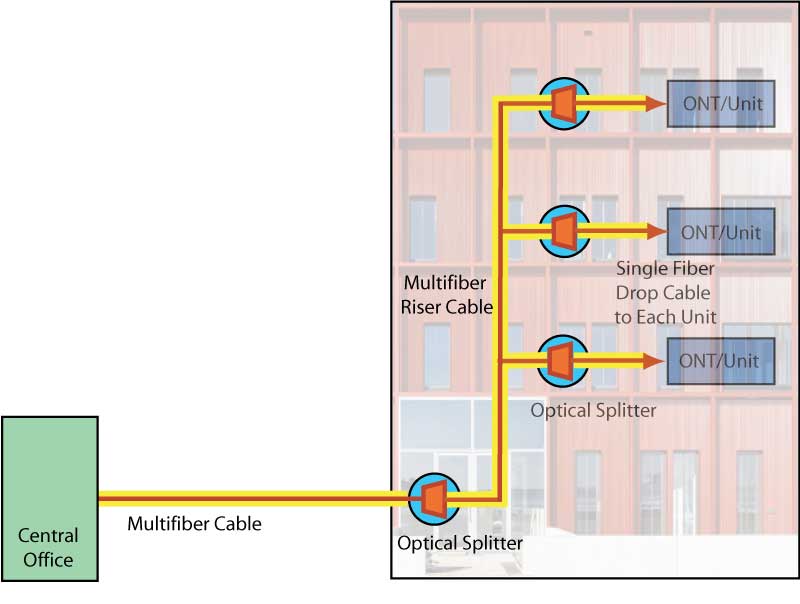

Where subscriber density is lower, it's

common to cascade splitters where splitters with fewer

splits are connected to other splitters in series like

this:

Cascaded splitters are useful for areas

like the suburbs or rural areas where subscribers are

spread out but often in clusters. An example is to use a 4

or 8 port splitter to serve a street in the suburbs or a

small cluster of homes in a rural area or to connect

multiple users in a multi-dwelling unit (apartment or

condo building - see the section on MDUs below.)

PONs are standardized on splits of 32

or 64 per OLT port, and the economics of the electronics

depends on the efficient use of the OLT port. But

subscriber take rates are not 100%, so one needs to leave

spare ports for drops to future subscribers. Some systems

limit subscribers to 20-24 per port to allow new

subscribers. Others have built networks around a fiber

from the head end to every potential user and leaving the

fibers to non subscribers dark. The central office houses

all the splitters which can be fully populated, optimizing

the electronic ports. New subscribers already have a dark

fiber and just need plugging into a splitter at the head

end. New OLT ports are added as subscribers fill up ports

already in use.

Much of the design time is likely to be

spent deciding where to place splitters to optimize the

cable plant. In dense urban areas, there may be locations

where subscriber density is high enough to justify using a

single 32 port splitter. In less dense areas, it will

probably be more efficient to cascade splitters to equal

the 32 splits. Splitters come in binary ratios (2, 4, 8,

16, 32) and can be cascaded in any sequence as log as the

multiplied split ratios are no more than 32, e.g. 2+16,

4+8, 2+4+4, etc.

Choosing splitter locations can be

challenging, but generally it is done where one finds

groups of subscribers in close proximity so the length of

drop cables is shortest. In urban or suburban areas, one

can look at the number of residents in a building or the

number of homes on a street. In dense population areas, a

pedestal or underground fiber distribution hub (FDH)

containing splitters may be placed in a neighborhood and

drops run from the FDH to buildings from there. If a

building has many residents, a smaller FDU with splitters

may be placed inside the building with individual fibers

run to each subscriber. A large FDH is not needed for

splitters. Splice closures often have provision for

splitters, so a backbone or distribution cable can be

split out to drop cables for subscribers in the closure.

That closure can be in a manhole or handhole if the cable

plant is underground or suspended with aerial cable.

PON Loss Budgets

PONs are designed around a certain

split ratio for OLTs and have a range of power at the

receiver that must be met for the network to function. For

example, GPON has a Power Budget range of 13dB

(min) to 28dB (max) w/32 split. When calculating the loss

budget, one needs to ensure the loss is at least 13 dB but

less than 28 dB, usually less the acceptable loss margin

for the link. The minimum of 13 dB is usually not going to

be a problem since splitters add large amounts of loss.

PON network diagram with loss budget components noted.

PON networks with splitters require

calculating a loss

budget like any other network. Besides the losses

from fiber length, splices and connections, one must add

in the loss of the splitters. Each split of a factor of 2

loses 3dB and in addition there are losses due to splitter

inefficiency, so losses can be quite high. In the example

above, the splitters are cascaded so one would have a 1X4

with 7 dB loss and a 1X8 with 11 dB loss to include in the

loss budget for a total splitter loss of 18 dB. The the

loss of the remaining components in the cable plant would

be added.

| Splitter

Ratio |

1:2 |

1:4 |

1:8 |

1:16 |

1:32 |

| Ideal

Loss / Port (dB) |

3 |

6 |

9 |

12 |

15 |

| Excess

Loss (dB, max) |

1 |

1 |

2 |

3 |

4 |

| Typical

Loss (dB) |

4 |

7 |

11 |

15 |

19 |

After calculating a loss budget, it

needs to be compared to the power budget of the PON

version or link (if using P2P architecture) chosen

for the network.

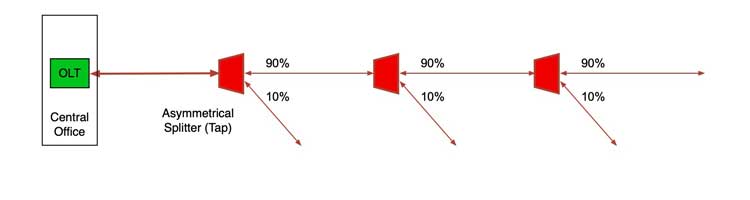

Rural Architecture Options

Rural areas are characterized by low

subscriber density and long distances, not the conditions

PONs were designed for. There is a "long reach" GPON

version with a capability of 64 users and 60km that can

work in some applications. Another option sometimes

considered is not using splitters but taps, special

splitters at drops that are not symmetrical - multiple

equal outputs - but split off a small portion of the

signal in the fiber, like 10% and pass 90% along to the

next drop.

The problem with the tap architecture

is the inefficiency of tap splitters, The excess loss in

taps can be as much as 1dB per tap. That excess loss adds

up fast, rapidly cutting the length the network can reach

(1dB = ~2.5km of fiber). FOA has done an analysis

of the use of taps in rural FTTH which can be used

as a model for analyzing the use of taps in any FTTH

network.

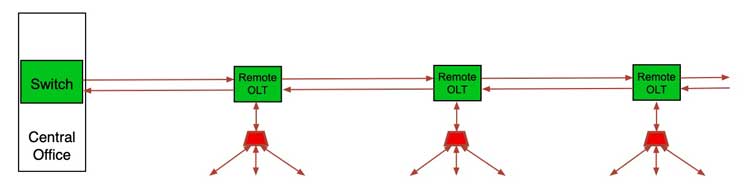

Another option which has been developed

for low subscriber density like rural areas uses is a

remote OLT with only a few ports. OLTs designed for CO use

generally have options for many OLT ports because they are

intended for applications with large numbers of users -

hundreds of thousands in a dense city. But rural areas may

only have a few subscribers in a small town or scattered

along country roads. Large numbers of ports are not

needed. What is needed is an architecture that allows a

service provider to connect users spread out over large

areas.

The remote OLT option allows creating a

"head end" periodically along a rural road where users are

grouped. The Remote OLTs can take advantage of the fibers

already installed along many roads and since some allow

"daisy-chaining," the use of two fibers along the route is

all that's needed. They are in small enclosures similar to

CATV amplifiers and can be mounted on poles or suspended

from messenger wires.

The

long reach version of GPON is another option for rural

areas. It can reach 60km with up to 64 users per port, but

in countries like the US, 60km is short compared to the

distances in rural areas. And it will use much more fiber

than the remote OLT architecture.

FTTH Fiber

Optic Cable Plant Design

When FTTH using PONs first began being installed around

2005-7, it was considered a extension of regular telephone

systems, where subscribers were being connected to a

telephone system replacing copper wires. Cabinets or

pedestals containing the PON couplers were placed near a

group of subscribers. Cables were pulled between the

cabinet and the central office containing the PON system

electronics and spliced on each end by the usual outside

plant (OSP) installation crews and were tested as was

normally done with telecom fiber optic networks.

On the subscriber end, drop cables were

placed to the home and connected either by splicing or

installing connectors (usually APC connectors to prevent

reflectance problems). Drop cables could be installed

aerially, underground or buried. Installing the cables

through customer's yards created a problem as it is time

consuming and disruptive to the customer. Simple trenching

was sometimes dropped in favor of directional boring, an

expensive process. Connectors were installed either by

fusion splicing on pigtails or using splice-on connectors.

After the cable plant was installed,

the optical network terminal (ONT) was installed at the

home. Some systems installed ONTs on the outside of the

house, some inside garages, some inside the home. Some

home builders built new homes with provision for the ONT

inside the home and installed cabling and power to the

same area to create a home prepared for broadband. See the

examples below.

After the ONT was installed and tested,

it was necessary to complete the installation by

connecting the customers phones, TVs and computers. In

all, three or four groups of installers of different

experience and skill levels were needed to install a FTTH

customer.

Systems Evolving With Experience

After some experience with the systems,

methods were tried to simplify the process and cut costs.

A big breakthrough came with the development of prefabricated

cabling systems (sometimes call pre-terminated

cabling) that eliminated the need for most of the

splicing. Cables with weatherproof connectors were

purchased already made to the lengths needed and pedestals

were factory made with connectors for the drop to the home

and a cable ready to splice onto the cable installed from

the central office.

The prefab drop cables could be run

aerially, even lashed to current telephone wires. They

were also small enough they could be pulled through small

PVC conduit often installed to home in new construction.

Most of the systems use multi-connector cables near the

homes being connected so homes can be connected during the

first install or later when more customers decide to take

the service.

Aerial

installation in Santa Monica, CA, using prefab cabling

system.

Closeup of the six-port drop.

If the cable is underground, it will usually be

pulled through conduit from connection to the distribution

cable or the splitter to the home. Here a preterminated

system has two home drops connected to the distribution

cable.

Underground installation of prefab cable system in Long

Beach, CA.

Other systems used microduct

installation which requires little or no digging to

install underground or under a road. Microducts are

designed to accommodate small microcables that are

installed by "blowing in" the cables, a technique used in

many systems.

Microduct

installation using a saw on a paved street.

The splitter can be housed in a central office, a

pedestal or even a splice closure used for drops in the

neighborhood near the homes served. The advantage of PONs

is that the pedestal or splice closure is passive - it

does not require any power as would a switch or node for

fiber to the curb.

On the left is a typical pedestal that has connections to

the CO, splitters and fibers out to each home in a sealed

enclosure. Pedestals like this can be specified and

purchased ready to install; installation involves only

splicing the distribution cable to a short cable provided

as part of the pedestal. On the right, a tech is splicing

drop cables in a closure that has provision for a splitter

in the splice tray (red arrow.)

A network interface device called an ONT

(optical network terminal) containing a fiber optic

transceiver will be installed at the house. Some are

installed on the outside of the house, others are indoors.

Some houses are now being built with cabinets in the house

for connecting to the FTTH fiber and then distributing

phone, TV and Internet connections throughout the house

over state of the art cabling. The incoming cable needs to

be terminated at the house, tested, connected to the

interface and the service tested.

Basic Component Selections

Two components of FTTH cable plants are

almost universal. Every network should use standard

singlemode fiber, G.652, or its bend-insensitive

equivalent G.657, in all the cabling. This is regular SM

fiber and is appropriate for current PONs as well as

upgrades to 10G PONs in the future. Connectors are

generally SC-APC, the SC connector with an angled physical

contact ferrule to reduce reflectance problems in the

short cables and splitters. Check equipment requirements

to see if SC-APC connectors are specified or if SC-PC is

required for the transceivers. Beyond these basic choices,

cable designs and other hardware will be chosen for the

environment of the cable plant.

New Cable Types And Hardware For Subscriber Drops

Several new cable types were developed for use in

FTTH. Until FTTH, most single fiber cables were

complicated structures with tight buffered fibers and

aramid fiber strength members inside plastic jackets,

usually 3mm in diameter or sometimes smaller. While these

cables were adequate for factory termination into

prefabricated assemblies, they were not ideal for field

termination or use inside buildings. With the advent of

bend-insensitive fibers that required less protection, a

new type of drop cable was developed that molded a

bend-insensitive fiber inside a small plastic structure

surrounded by metal or aramid fiber strength members. This

design could also be made as a "figure 8" cable with a

messenger for support in aerial installation. Here are

some photos of this type of cable.

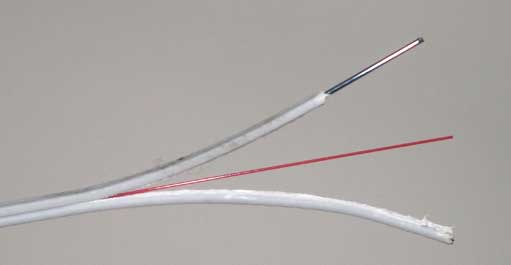

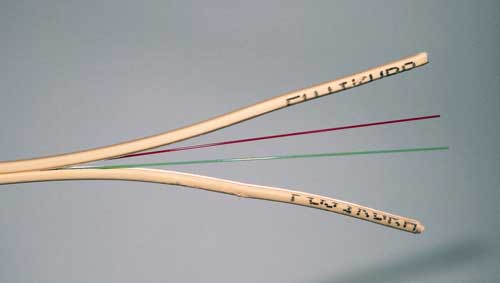

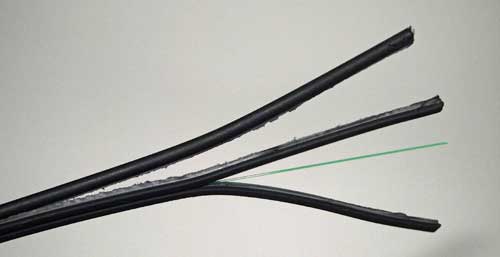

FTTH Drop Cable,

1 fiber, showing steel strength member

FTTH Drop Cable,

2 fiber

FTTH Drop Cable,

1 fiber with messenger for aerial support

To work with

these cables, special fiber closures were developed that

are more convenient for field installation.

This

closure has entries for distribution cables, including one

coming in and one going out - continuing on to

another closure for daisy-chained cables using midspan

access. There are multiple outputs for drop cables which

are terminated in connectors. Some closures like this one

have provision for splicing on pigtails to terminate the

distribution cables while others are designed for direct

termination using prepolished-splice connectors. Patching

with connectors in a re-enterable closure allows adding

new drops when needed.

Early ONTs being installed on the

outside of the house looked like this. Most networks have

moved to just installing a demarcation box on the outside

of the house where the drop cable is connected to a fiber

optic cable running into the house. This connection allows

for a test point for techs where they do not have to enter

the house to see if signal is being received at the house.

Inside, the FTTH ONT is now a small box like a cable or

DSL modem.

A house with

premises cabling has this cabinet inside the home for

distributing services from the FTTH connection. Some

builders now include equipment boxes like this in new

homes.

Design For

Geography

The best way to understand the options in FTTH network

design is to consider several very different types of

networks which differ by subscriber density, geography and

technical issues which affect the design decisions that

must be made.

- Urban

- Suburban

- Multi-dwelling

Units

- Rural

Urban

FTTH Networks

Urban FTTH networks feature high

subscriber density requiring less fiber because the

distances are shorter and more splitters and head-end

electronics because the subscribers are more numerous.

In dense urban areas, many if not most users are going

to be in MDUs, so the OSP design and installation

can be simpler - just getting fiber to the building -

but inside the premises it may perhaps be more

complicated - how to run fiber inside the building to

each subscriber. See the section on MDUs below.

Inside a city, the most complicated

part of designing a network is accommodating the cables

needed to get from the CO/Head End to the building where

the users are located. Cities often have congested

conduits with too many cables already, so running more

cables can be a problem. Techniques exist to add cables

to crowded ducts, sometimes removing fiber ducts that

have only one fiber and replacing them with microducts

with multiple microcables or using fabric ducts that can

double or triple the number of cables a conduit can

accommodate. Rather than digging up streets, systems can

be built using microtrenching with minimal impact.

Techniques also exist to remove the core of CATV

hardline coax and use the jacket as a fiber duct and use

robots to install cables in sewers. Fiber optic

companies can be quite inventive.

Most cities have the majority of

cables underground, but many also have aerial cables in

alleys. If possible, running FTTH cables in alleys

behind buildings and using aerial drop closures will

greatly reduce the cost of building an urban FTTH

network.

But before deciding how to install

more cables, inventory what exists already. Many cities

have fiber optic cable plants installed for city

communications, security, traffic systems, citywide

WiFi, etc. and may have spare fibers. If no spare fibers

exist, it may be possible to use wavelength division

multiplexing to get more links. Likewise, other service

providers including electrical utilities may have fiber

or spare conduits that can be used, and their interest

may be higher if they can benefit from the new network.

Another problem in cities is finding

space for fiber hubs where drop cables connect to the

distribution cables. They can take up lots of space and

be a problem in cities where sidewalk space is at a

premium and underground utilities crowd the areas under

streets and sidewalks. Putting hubs inside buildings may

be much easier that doing major construction outdoors.

FTTH In

Multi-Dwelling Units (MDUs)

Multi-dwelling units (MDUs in some suppliers jargon) are

sometimes handled like FTTC, where fiber is brought into

the building and individual units are connected over

copper cables, either twisted pair from phones or computer

networks or coax from CATV or satellite. A standard for

Ethernet over CATV Coax (MOCA) is often used to make this

connection if the telephone wires are inadequate, but be

careful as those cables may not be owned by the building

owner but the service provider.

But MDUs are ideal

for FTTH (that is to each unit in the building) since

there are many users in a very small space and fiber

lengths are short. Besides using less fiber, MDUs

generally require less time per drop to install. One issue

is where to place PON splitters. If it is a small

building, the splitter(s) can be installed at the entry

facility and individual cables run to each unit. In larger

buildings, splitters can be cascaded and a splitter placed

on each floor (if space permits) and short cables run to

each unit.

Each building should have some space

for the fiber to enter the building, have a rack or box

for splitters and connecting to cables to run to each

user. Since the PON network is passive, it is not

necessary to have power at this location, just some space

and room to work on the hardware connecting or moving

users.

A major problem in older buildings has

been finding places to run cables to each subscriber, but

new types of bend-insensitive

fiber and the special small drop cables shown above

make it easy to route fibers along walls or place in

stick-on raceways on the walls. Here is an example from

Corning on how bend-insensitive fiber can be treated

without problems, but we offer a caution regarding

stapling these fibers - it could be a long-term problem

and should be avoided in our opinion.

Bend-insensitive

fiber installed in older building (L - Corning) and

hardware to stick cable on the wall (R-3M).

Cables installed in buildings should be

done neatly. Residents and owners are likely to complain

if the cabling is done badly.

Suburban FTTH Networks

Suburban networks are less dense and

installing new cables can be much easier. Some areas have

aerial infrastructure which makes installation much

easier, since aerial installation is always easier and

less expensive and special FTTH closures can allow placing

fiber hubs with splitters on poles or suspended from

messenger wires. Aerial drops are easier to individual

homes or buildings also. If the cables must be

installed underground, which is becoming more common, and

conduit space is not available, microtrenching along the

curb can simplify the installation. Handholes will need to

be located where splitters and drop closures are located.

Underground drop cables to each home

can be a problem since the cable or ducts needs to go from

a curbside handhole through the customer's lawn. Running

the cables alongside the driveway alleviates most of the

problem in many drops. If the drop cable is buried in the

lawn, there can be a problem in the future with the owner

digging up the cable because they forgot where it was

located or a landscaper or installer of invisible dog

fences starts digging. As close to the driveway as

possible is safer. Directional boring is also possible but

can be extremely expensive and has the danger of hitting

current utilities and causing damage. Not all - probably

few - owners know where their underground utilities are

located and using locating equipment is time consuming and

expensive. Gas lines are especially dangerous and can

cause fires and explosions.

From the outdoor demarcation box, a

fiber needs to be run to a location inside the home to the

location of the FTTH ONT. In any indoor installation, it

is important that the work be done neatly. A survey of the

home to locate where other cables (telephone and CATV or

satellite) enter the building and are run indoors can help

locate the easiest path for the FTTH fiber cable. As with

MDUs, the resident/owner will expect the cables to be

installed in a neat and workmanlike manner.

Rural FTTH

Rural FTTH is going to be more

expensive no matter what you do. Service providers have

used wireless drops to avoid running long fibers to each

subscriber, but the limited bandwidth, cost of the

equipment on a pole and at the subscriber (not to mention

updates) and the lifetime of powering it may prove to be

no bargain compared to running a fiber optic drop cable to

the subscriber. Most rural networks are aerial which makes

the cost much lower than underground. If the utility poles

already have low voltage cables, generally aging telephone

wires, the FTTH fiber distribution cable can probably be

lashed to the same messenger, by far the least expensive

way to install fiber.

The big problem with rural FTTH is

distance. That means longer cables and more cable and

installation costs. It also means that many networks will

exceed the length maximum of GPON while having fewer

subscribers than the number allowed by splitting. The

solution in many cases may be using the remote OLT

architecture shown above. Cables can be run alongside

rural roads and the remote OLTs installed in areas where

there are multiple users within the reach of the OLT.

Electrical utilities and coops have

rights of way and transmission lines into rural areas that

are ideal for FTTH. Many utilities already have fibers

installed, often in optical power ground wire, but

sometimes have only a few fibers available. WDM

(wavelength division multiplexing can expand the fibers

capacity if permitted. When you already have towers or

poles, installing fiber is easy with several options.

Cable can be lashed to messengers even overlashing to

current fiber or copper cables. ADSS (all-dielectric

self-supporting) fiber optic cable can be installed on

poles or towers without a messenger for long spans. There

are even methods that use lightweight cables that can be

wrapped around current-carrying conductors.

Rural telephone companies also have

rights of way and cable infrastructure. Many already run

fiber backbones. For them, the biggest obstacle is usually

financing and fortunately there are programs to provide

grants and loans for rural broadband.

Cable cost is higher for the longer

distances, but fiber optic cable is very inexpensive,

especially when compared to installation cost. The cost of

fiber itself is only part of the cable cost; the materials

used in the cable predominate for cables with fewer than

24 fibers, so buying or installing cables with fewer than

24 fibers is generally not cost effective. And installing

more fibers means that spare fibers can be leased to other

carriers - municipal/county/state agencies, telecom

companies, wireless service providers, electrical

utilities, etc. to defray the cost.

Additional

Reading on Rural FTTH

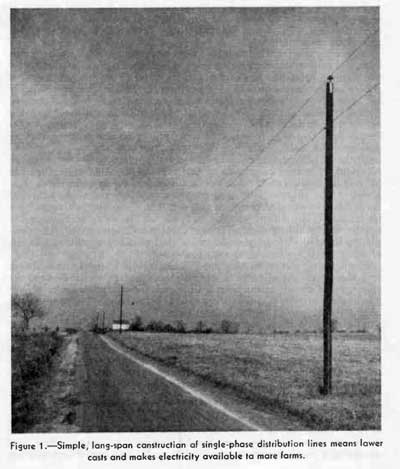

The

August

2021 issue of the FOA Newsletter compares rural

broadband today with rural electrification almost a

century ago. The situations are quite similar and the

solutions, including assisting rural electrical or telco

coops, are quite the same.

From the 1940 USDA yearbook article on rural

electrification.

Designing The FTTH Central Office or Head End

Whether you call it a central office or

head end depends on whether your background is telco or

CATV. IT types might call it the equipment room or data

center. But the location of the electronics for a FTTH

network is another design decision that requires careful

consideration and planning. The location should generally

be as central as possible to simplify and perhaps minimize

cable lengths. Space is not a big problem as FTTH PON OLTs

are not large because each OLT port serves as many as 32

or 64 users. But the design must accommodate cables and

electronics and allow for future expansion.

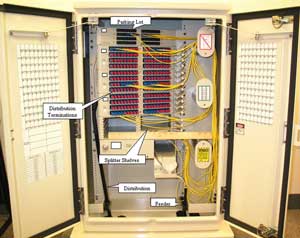

FTTH PON OLT head end for ~5,000 subscribers

The head end is also an entrance

facility, with incoming fiber optic cables from the

outside Internet connection and outgoing cables from the

OLT. Sufficient patch panel space is required for both

incoming and outgoing cables. Hardware needed includes

cable trays and management as well as rack space for the

patch panels. There will have to be rack or wall space for

the interface to the Internet service provider. This is

essentially a router with incoming signals at high speeds.

The router connects to the OLT to handle the Internet

connections.

The OLT connects the Internet to

the users by converting signals to PON protocols and

connecting users. The OLT does lots more also, including

managing users and encrypting signals for subscriber

privacy. The OLT requires a trained operator, at least

part time, to manage subscriber connections and other

regular service, so plan on having an operator attend

training by the equipment provider.

Since the subscribers require 24/7/365

operation, the entire electronics package needs

conditioned power and an uninterruptible power supply

(UPS) that can keep it going for at least 8 hours in a

power outage. Many FTTH systems also provide – or at least

recommend – a UPS at the subscriber’s site to also provide

nonstop operation.

Before

you Start, Things To Remember

Uniqueness:

Like most fiber optic networks, every FTTx installation is

unique. It must be designed for the location it is to

serve and choices on components and installation methods

should be optimized for the system. Construction and

installation methods may include every type of OSP

installation. Suppliers familiar with FTTx can advise

customers on what others have done to make

installations simpler, easier and less expensive. Most

systems prefer to use as many factory-made components as

possible as they are generally less expensive than doing

the same work in the field. New installation methods

should be considered as well to reduce costs.

Consultants:

Be wary of consultants. Consultants can be

extremely valuable in designing a FTTH system, as long as

they have relevant experience, are up to date on new

components and techniques and are highly recommended by

previous clients. Unfortunately we have seen problems with

consultants, including over-designed networks with costs

much higher than necessary, installation practices

recommended that were unnecessary or ignore newer

technology, systems designed around components that were

higher performance (and price) than necessary, and in one

case a consultant took the clients payment, went away for

a year and came back with an admission that they could not

design the network (but they kept the consulting fees.)

Contractors:

As with any fiber optic project, the quality of the

installation depends on the quality of the installer. Look

for contractors with knowledge, experience and references.

And preferably relevant certifications like the FOA CFOT.

Be especially wary of subcontractors. Any subcontractors

should have equal qualifications and be approved by the

network owner. We have seen landscape contractors with no

fiber training used as subcontractors for cable plant

installation - one cut several cables to buildings that

had been installed by a member of the FOA advisory board!

Call Before You Dig! Every day some major fiber

optic cable is cut by a contractor. The jurisdiction

issuing permits should help you with locating other buried

utilities. There is a service that helps you locate

underground utilities that may be in your construction

path. See the FOA web page on Digging

Safely.

What Fiber Do

You Already Have? Before you

design or install a new fiber optic cable plant, inventory

the fiber you have already and/or negotiate to lease fiber

where others have cables with dark (unused) fibers. Also

talk to other organizations who may need communications to

see if they want to share costs or lease dark fibers or

communications links from you. Cities, counties and states

need fiber. Utilities need fiber. Fire and life safety

organizations need fiber. Traffic departments need fiber.

Cellular companies really need a lot of fiber.

What Other

Services Can Share The Fiber? Consider what

other services than FTTH you can carry on your fiber optic

cable plant - cellular backhaul, traffic systems,

security/surveillance systems, leased fiber, etc. to

generate additional revenue. A few years ago a large

American city sent out a RFP (request for proposal) for an

urban FTTH network. The document dealt strictly with FTTH

to connect the city's citizens with fiber and ignored all

the other services the city had that already used or

needed fiber - city communications, security/video

surveillance, intelligent traffic management, public

transportation communications, wireless networks(small

cells and 5G), utility communications, etc., etc., etc.

Dig Smart -Dig

Once: This same document also covered

the difficulty of urban installation - digging up streets

already filled with underground utilities, limited space

for pedestals, few options for aerial cable and

other issues that are typical problems for urban fiber

installation. No mention of "Dig Once" to make future

installations easier. Share fibers. Use spare fibers. Use

additional wavelengths in current fiber. Consider all the

alternatives. Plan ahead - future proof is a myth, but one

can make certain decisions that will make the future

easier. If you are considering using

FTTH design software, ask to talk to customers who have

used it. Determine what you need to know first in order to

use it, e.g. GIS data on every utility pole, manhole or

handhole, subscriber location, etc. and how much training

it takes to become proficient. Will you use your personnel

or hire outsiders, and how do you evaluate them.

Cost Savings:

Fiber optic cable and components are not

expensive, but labor is. Saving money on components may

look good in first analysis, but more savings will come

from optimized designs and efficient installation

practices. More experienced contractors are more efficient

and may save costs by their speed and efficiency.

And design for the future - if you dig a trench for

anything, not just fiber but any underground utility, bury

a number of fiber ducts for future use, install cables

with more fibers than you need - lots more - fiber is

cheap, installation is expensive. The program is called

"Dig Once."

Take Rates Are

Important: "Take rates" for new FTTH networks

vary from low to high, depending on the satisfaction with

the current ISP (Internet service provider.) When Google

Fiber started in Kansas City, the take rate was high

because the current service was bad, but in later cities

when the local ISPs knew they were coming and improved

their service and/or lowered their prices, the take rate

was lower. Competition tends to drive take rates and take

rates determine the economics of the system, Know your

competition. Offering gigabit services are often the top

selling point of FTTH. Every GPON network is a gigabit

network, but subscribers can opt for slower speeds at

lower costs.

What Makes

A Successful Fiber Optic Project?

People call FOA for advice all the time. Most of the calls

deal with technical questions about products, installation

and testing. But in one call; a manager who was starting

to plan a fiber optic project wanted advice on how to

proceed. It was a long call! His basic question was “What

does it take to have a successful fiber optic project?” We

responded with 4 words: financing, commitment, expertise

and patience. (This section is repeated from the

introductory section on FTTH because it's important for

the designer and managers of a FTTH project.)

Financing: The story goes that

someone asked Neil Armstrong what he was thinking about

while sitting on top of the rocket ready to launch Apollo

11 to the moon. “Every part was made by the lowest

bidder,” was supposedly his reply. (The same quote has

been attributed to most early astronauts!)

Fiber optics are not necessarily

expensive; in fact, fiber has been used so widely because

it is the least expensive communications medium in

virtually all projects. But fiber optic projects may

require a lot of construction which makes the project

expensive. Like all other projects, it never pays to cut

corners. Planning and running the project properly is what

saves money, trying to cheapen the project. Not all jobs

should go to the lowest bidder, unless they meet all the

criteria for a qualified bidder. Likewise, one needs to

ensure that when a project starts, there are funds

available to complete the job properly, including some

extra for unplanned changes or modifications.

Commitment: Just like having

sufficient finances to compete the project, one needs a

commitment to finish the job once it is started. Changes

of management or changes in governments often lead to

confusion or even modifying a project in midstream. There

is nothing wrong with making changes based on what learns

as the project progresses; it may even involve greater

efficiency or cost savings, but arbitrary changes may

jeopardize the project's timetable, completion or even its

usefulness.

If the project is under the auspices of

a government entity, changes in administration or

management that causes changes in a project will

invariably make it more expensive and may jeopardize the

success of the entire project. Ideally, the personnel who

propose, design and plan the network should see it to

completion.

Expertise: Fiber requires

expertise and experience. It's obvious the installers need

to know what they are doing, but in reality, so must the

managers who work for the organization that is contracting

for the work. There are many instances of projects where

the managers signed off on the project when it was

incomplete or improperly installed. The only way to

properly manage a project is to understand every aspect of

it well enough to know if it is being done properly and

when it is actually complete.

Planners, designers, contractors and

installers should all be trained and certified

as well as being experienced with good references. That

holds doubly so for consultants. In many places, to be a

consultant or cabling contractor means little other than

registering as a business and advertising your services.

Some of the problems we've seen with outside services,

include consultants who took contracts, spent time on a

project, then told the customer they could not help them

with the project, but kept the money.

We have seen contractors doing shoddy

installations, ruining expensive fiber optic cable during

pulling and leaving jobs half done but getting paid

because the customer knew no better. One of the biggest

problems is subcontractors. A contractor with good

credentials gets the job but subcontracts some of the work

to a contractor who will do the work at a lower price, but

does not have the training or experience (or motivation)

to do it right. In your contract with an installer, we

recommend a clause giving the project manager

responsibility for evaluating and approving all

subcontractors.

The manager must know better to prevent

problems. FOA also has pages on what

the manager needs to know.

Patience: From concept to

acceptance, a typical OSP fiber project can take 2-5 years

and a premises project 1-2 years. It depends on the size

of the project, the time to properly design it, create

project paperwork, get permits, buy components, hire

contractors and properly install it. Proper

workmanship takes time and is not easily rushed. Saving

time generally means cutting corners and that is often the

cause of the problems encountered. Take your time, plan,

design, select, install, test and document your network

properly.

And by the way, "future proofing" is a

myth! Who would have known in 1990 how ubiquitous the

Internet would be today? How reliant we could be on

smartphones other mobile devices? How many workers would

be working remotely or using videoconferencing for

meetings? Technology moves too fast and is too disruptive

for anyone to make reliable predictions. The IBMer who

developed MRP - the original company organizational

software - used to tell everyone, "A forecast is wrong

from the moment it is made." Plan for the future, but

assume you will upgrade, change directions, etc. driven by

new tech and changes in the world around us.

- Technical

Information on FTTX From The FOA

Online Guide:

- FTTH

Introduction

- FTTH

Architectures,

- FTTH

in MDUs (Multiple Dwelling Units)

- FTTH

PON Standards, Specifications and Protocols

- FTTH

Design

- FTTH

Installation

- FTTH

Customer Premises Installation

FTTH

Network Testing

FTTH

Case Studies: Do-It-Yourself FTTH

FTTH

Project Management

Migration from GPON to 10GPON

- The

Fiber Optic Association Fiber To The Home Handbook:

For Planners, Managers, Designers, Installers And

Operators Of FTTH - Fiber To The Home - Networks

The

Fiber Optic Association Fiber To The Home

Handbook Available

in paperback or as an eBook on the Amazon

Kindle Available

direct from Amazon.com,

local booksellers and other distributors.

- Training

& Certification

Fiber

U Online FTTx Self Study Program (free)

- FOA

Certification Overview

FOA

FTTx Certification Requirements

FOA-Approved

Training Programs

Table of Contents: The

FOA Reference Guide To Fiber Optics

|