Fiber To The Home

Installation

There is

probably no way to generalize on the installation process

for FTTx since every system is unique and, in some cases,

every subscriber is different. Rather than telling you how

to install FTTx here, we will try to illustrate some of

the ways that others have installed their systems and

offer advice on how to install systems most efficiently.

Instead of duplicating information

elsewhere in the FOA

Guide, which has a long section on fiber

optic construction and outside

plant installation, we will focus on FTTH specific

topics and link you to some FOA online materials that

cover relevant topics. We also recommend you read the

FOA Guide pages on FTTH and especially the page on FTTH

Network Design before starting on this page.

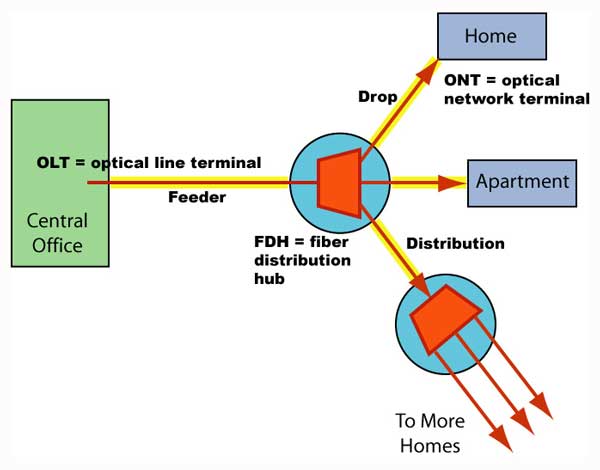

Most

FTTH networks are based on a PON network. The

drawing below defines the network: a "feeder" cable

extends from the OLT (optical line terminal) in the CO

(central office) to a FDH (fiber distribution hub) where

the PON (passive optical network) splitter is housed. It

then connects to "distribution" cables that go out toward

the subscriber location where "drop" cables will be used

to connect the final link to the ONT (optical network

terminal).

The installation of the cable plant to

the point where the drop goes to the subscriber is

basically standard outside

plant construction and outside

plant installation which you should be familiar with

for FTTH installation. Installation of feeder and

distribution cables generally follows standard OSP

practice, but the drop cables are unique to FTTH. The

cables are often different from normal OSP cables because

they have fewer fibers ( 1 or 2 generally) and are more

often factory terminated for plug-and-play at the

subscriber interface for single family homes. MDUs

(multi-dwelling units) will generally follow fiber to the

building conventions with patch panels inside the

building.

Preterminated

or prefab cables became popular when FTTH service

providers realized that they could eliminate the need

for experienced splicers at the subscriber installation.

Instead the home installation tech could simply plug in

the drop cable, hook up the ONT and connect customer

devices. The would only get involved with running cables

inside the house if necessary.

Prefab cables can be factory terminated

on one end or both. If the cable plant used these drop

boxes for prefab cables (below), the drop cables will be

terminated on both ends and excess cable will be stored in

service loops. Installation of the cable is simply

attaching aerial cables, pulling cables in conduit or

using simple trenching techniques to bury the cable in the

subscribers lawn. Keeping buried cables close to sidewalks

and driveways minimizes the possibility of them being dug

up. And like all underground construction, the installer

needs to be aware of any underground utilities in the

subscriber's yard, especially sprinkler systems or

invisible animal fences which are often poorly documented.

Closeup of the

six-port drop.

Some special FTTH fiber closures for drop cables require

terminating the drop cable to connect it to the box. Patching

with connectors in a re-enterable closure has become

a popular option to splicing as it allows adding new

drops when needed. These closures

generally use splice-on connectors, either mechanical or

fusion splices, on the bare end of the drop cable. This

minimizes the problem of storing excess lengths of cable

in service loops. The drop cable can be installed at the

subscriber end to the closure then terminated,

eliminating most of the excess cable storage.

This closure has entries for distribution cables,

including one coming in and one continuing on to another

closure for daisy-chained cables. There are

multiple outputs for drop cables which are terminated in

connectors. Some

closures like this one have provision for splicing on

pigtails to terminate the distribution cables while

others are designed for direct termination using

splice-on connectors using either fusion or mechanical

splicing.

If the design calls for termination

at the customer premises, these same splice-on

connectors are generally used to get reliable

terminations quickly. The mechanical spice on connectors

require special tool kits and some practice to get good

yield. The fusion splice on connectors require a fusion

splicer but several are available at costs not much

greater than the took kits for the mechanical splice

types and require less skill to get good yield.

We're focusing on the fiber part of

the installation but the FTTH home tech will have to

know how to connect fiber, set up the ONT and connect

all the subscriber's devices. That is a very different

skill from fiber optic installation.

Summary

Like

most fiber optic networks, every FTTx installation is

unique. It must be designed for the location it is to

serve and choices on components and installation methods

should be optimized for the system. Installation methods

may include every type of OSP installation. Suppliers

familiar with FTTx can advise customers on what other

systems have done to make installations simpler, easier

and inexpensive. Most systems prefer to use as many

factory-made components as possible as they are generally

less expensive than doing the same work in the field. New

installation methods should be considered as well to

reduce costs.

Contractors need to be well

trained (and preferably FOA Certified) and experienced in

the tasks they will be doing. Good installers will make

the installation easier, faster and cheaper because they

will make fewer mistakes. Because of the cost pressure on

FTTH service providers, contractors are often chosen by

price and then they often subcontract to cheaper, lesser

skilled contractors. There have been instances where

poorly trained installers, even landscape contractors,

have been hired to do installations and have cut other

fiber optic cables, punctured water mains flooding

neighborhoods or even breaking gas mains causing

explosions. Choosing wisely is important.

Technical

Information on FTTX From The FOA

Online Guide:

- FTTH

Introduction

- FTTH

Architectures,

- FTTH

in MDUs (Multiple Dwelling Units)

- FTTH

PON Standards, Specifications and Protocols

- FTTH

Design

- FTTH

Installation

- FTTH

Customer Premises Installation

FTTH

Network Testing

FTTH

Case Studies: Do-It-Yourself FTTH

FTTH

Project Management

Migration from GPON to 10GPON

- The

Fiber Optic Association Fiber To The Home Handbook:

For Planners, Managers, Designers, Installers And

Operators Of FTTH - Fiber To The Home - Networks

The

Fiber Optic Association Fiber To The Home

Handbook Available

in paperback or as an eBook on the Amazon

Kindle Available

direct from Amazon.com,

local booksellers and other distributors.

- Training

& Certification

Fiber

U Online FTTx Self Study Program (free)

- FOA

Certification Overview

FOA

FTTx Certification Requirements

FOA-Approved

Training Programs

Table of Contents: The

FOA Reference Guide To Fiber Optics

|