- Uncle Ted's Guide To

- Communications Cabling

- Installing Wiring

- Everybody knows how to pull wire, right? Wrong! Mistakes in installation work can be difficult to detect. A mistake that could keep the entire system from working might not show up at all until the system is completely installed and turned on.

- The performance of the cabling network is heavily dependent on the installation. The components used in structured cabling installation have been carefully designed and exhaustively tested to meet or exceed the requirements of EIA/TIA 568 for performance at 100-500 MHz. If the cable is not properly installed, performance will be degraded.

- Just like we keep harping on keeping the twists right down to the terminations, there are things you must realize to maintain the performance of Cat 5e /6/6A wire you paid for! First of all, pulling tension must be low - less than 25 pounds (11.3kg). That's not very much! Pulling at higher tension can stretch the cable and affect the twists in the pairs, and it's those twists that make the cable perform well at high frequencies.

- Likewise, kinking the cable by letting it get twisted or pulled around sharp corners can cause permanent damage. Damaged cable will probably not pass crosstalk tests.

- Most cable boxes are designed to allow easy pulling directly from the box. Gather up several boxes and pull a bunch of cables at once. Tape them together and attach a pull string or just feed them along by hand.

- You can pull from the telecom closet to the desktop or from the desktop to the closet, whichever is more convenient in the install you are doing. You can also pull to consolidation points then out to individual outlets or vice-versa, instead of pulling the bundle of cables all the way.

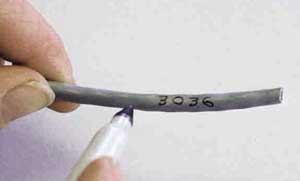

- One item to remember is there is usually 1,000 feet (about 300 meters) of cable in each box. Each cable is also marked with a distance every few feet (m) so you can keep track of length by reading the distance off the cable. Before you pull any cable from the box, find the distance marked on the cable and write it down on top of the box! That way, you can calculate the length of each cable you pull and more importantly, the amount remaining in the box! It's not good to start pulling a cable and find out it's not long enough!

- Likewise, mark every cable with a location it's going to. Mark it on both ends! You will save lots of time making the correct connections, recording test data and keeping records for moves and changes. A fine tip permanent marker will mark the cable neatly.

- Cat 5 e/6 should be installed on special hooks, bridle rings or cable trays that limit its bend radius and stress to preserve the performance. You cannot lay the cable on top of ceilings or hang from the drop ceiling hangers - most places it's against code! Penetrations of firewalls require firestopping to restore fire retardancy. You also have to keep the wire away from sources of interference, like fluorescent lights and power cables.

- Safety

- Power cables are also a safety hazard. Although this cable is called "low voltage," it runs in areas full of power cables that are a shock hazard. If you are not familiar with electrical safety, fire safety and inspections, I strongly suggest taking a course on the NEC (National Electric Code) to learn about these important topics. It could save your life!

Here is a summary of NEC references to VDV Cabling:

| Chapter | Article | Topic |

| 6 | 640 | Sound Systems |

| 7 | 725 | Remote-Control, Signaling and Power-Limited Circuits |

| 7 | 760 | Fire Alarm Signaling Systems |

| 7 | 770 | Optical Fiber Cables and Raceways |

| 7 | 780 | "Smart House" Wiring |

| 8 | 800 | Telecommunications Circuits (Telephone and LAN) |

| 8 | 810 | Radio and TV Equipment |

| 8 | 820 | CATV Systems |

| 8 | 830 | Network-Powered Broadband Systems |

- Other safety considerations:

- -Personal safety equipment - hard hat, safety glasses, appropriate gloves and steel toe shoes are recommended.

- -Observe ladder safety rules - many installations require work above ceilings.

- Inspection

- Electrical inspectors do not always inspect communications wiring. Nonetheless, take a moment to check with local electrical inspectors before you do any work in their jurisdictions. In most cases, the inspector of your installation will be the same person who signs you contract, although in some cases, the inspector will be a third party. Make sure you know who will inspect your work before you give your customer a final price. You must know what the inspector will expect of you and what he or she will be looking for.

- Installation Tips to follow:

- -All components must be Cat5e rated for Cat 5e performance (or whatever category rating is being installed)

- -Cable must be pulled from the reel or box without kinking

- -Cable must be pulled with less than 25 pounds (11.3kg) of tension

- -Use cable lubricant in conduit if necessary (but only special lubricant for that type of cable)

- -Cable must not be pulled around sharp corners or kinked

- -Inspect the cable route for surfaces that may abrade the cable

- -On riser installations (overhead installation), try to lower the cable down, not pull it up

- -Cables must be supported to prevent stress. Cable supports should not have sharp edges that may distort the cable

- -Cable ties must not be so tight as to distort the jacket of the cable. They are only used to prevent unnecessary movement of the cable, so snug is tight enough.

| (C) 2016 The Fiber Optic Association, Inc., all rights reserved. |