The

Fiber Optic Association

- Tech Topics

Safety in

Fiber Optic Installations

Download a safety poster from the FOA!

When most

people think of safety

in fiber optic installations, the first thing that comes to mind

is eye damage from laser light in the fiber. They have an image

of a laser burning holes in metal or perhaps burning off warts.

While these images may be real for their applications, they have

little relevance to most types of fiber optic communications.

Eye safety is an issue, but usually not from light in the fiber.

However, fiber optics installation is not without risks.

- Eye

Safety

Optical sources used in fiber optics, especially LEDs used in premises

networks, are of much lower power levels than used for laser surgery or

cutting materials. Even the output of OTDRs, WDM and fiber amplifier

systems, which are much higher than LED systems, are still well below

that used in laser surgery or machining.

- The light

that exits an optical fiber is also spreading out in a cone, so the

farther away from the end of the fiber your eye is, the lower the

amount of power your eye receives. If you are using a microscope, which

can efficiently focus all the light into your eye, it should have

infrared filters to reduce the danger of invisible infrared light.

- The

infrared light in fiber optic links is at a wavelength that cannot

penetrate your eye easily because it's absorbed by the water in your

eyeball.

Light in

the 1300-1550 nm range is unlikely to damage your retina, but might

harm the cornea or lens.

Light in

the 1300-1550 nm range is unlikely to damage your retina, but might

harm the cornea or lens.

- A typical

laser pointer, which has a beam that is collimated (not expanding), and

is at visible wavelength (650 nm) where the eye is transparent, is

probably more danger to the retina than a fiber optic link.

That being said, it's not a good idea to look into a fiber unless you

know no source is being transmitted down it. Since the light is

infrared, you can't see it, which means you cannot tell if there is

light present by looking at it. You should always check the fiber with

a power meter before examining it.

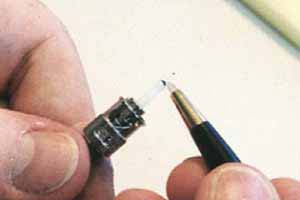

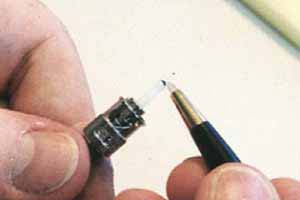

The real issue of eye safety is getting fiber scraps into the eye. As

part of the termination and splicing process, you will be continually

exposed to small scraps of bare fiber, cleaved off the ends of the

fibers being terminated or spliced. These scraps are very dangerous. If

they get into your eyes, they are very hard to flush out and will

probably lead to a trip to the emergency room at the hospital. Whenever

you are working with fiber, wear safety glasses!

Bare Fiber Safety

The broken ends of fibers and scraps of fiber created during

termination and splicing can be extremely dangerous. The ends are

extremely sharp and can easily penetrate your skin. They invariably

break off and are very hard to find and remove. Sometimes a pair of

tweezers and perhaps a magnifying glass will get them out. Most of the

time, you have to wait to let them infect and work themselves out,

which can be painful!

The broken ends of fibers and scraps of fiber created during

termination and splicing can be extremely dangerous. The ends are

extremely sharp and can easily penetrate your skin. They invariably

break off and are very hard to find and remove. Sometimes a pair of

tweezers and perhaps a magnifying glass will get them out. Most of the

time, you have to wait to let them infect and work themselves out,

which can be painful!

Be careful when handling fibers to not stick the broken ends into your

fingers. Dispose of all scraps properly. Some people keep a piece of

double stick tape on the bench to stick fiber scraps onto. I prefer to

use a dedicated container for all fiber scraps. In our training

programs, we use the same paper containers used for takeout at the

deli, in the pint size, with a lid. We put all the scraps in the

container, then when finished, put on the lid, tape it and dispose of

it later. Do not drop fiber scraps on the floor where they will stick

in carpets or shoes and be carried elsewhere-like home!

Obviously do not eat or drink anywhere near the work area. Fiber scraps

can get into food or drink and be swallowed. The scraps can imbed

themselves in you digestive system and never be found. Doesn't sound

too appetizing, does it?!

Materials

Safety

Fiber optic splicing and termination use various chemical cleaners

and adhesives as part of the processes. Normal handling procedures

for these substances should be observed. If you are not certain

of how to deal with them, ask the manufacturer for a MSDS. Always

work in well-ventilated areas. Avoid skin contact as much as possible,

and stop using chemicals that cause allergic reactions. Even simple

isopropyl alcohol, used as a cleaner, is flammable and should

be handled carefully.

Fire

Safety

Note that fusion splicers use an electric arc to make splices,

so care must be taken to insure no flammable gasses are contained

in the space where fusion splicing is done. Splicing is never

done in manholes where gasses can accumulate. The cables are brought

up to the surface into a splicing trailer where all fiber work

is done. Of course the splicing trailer is temperature-controlled

and kept spotlessly clean to insure good splicing.

Smoking should also not be allowed around fiber optic work. The

ashes from smoking contribute to the dirt problems with fibers,

in addition to the chance of explosions due to the presence of

combustible substances.

Electrical

Safety

You might be wondering what electrical safety has to do with fiber

optics. Well fiber cables are often installed around electrical

cables. Electricians are well-trained in electrical safety, but

some fiber optic installers are not. We've heard rumors of fiber

installers being shocked when working around electrical cables,

but know that two fiber installers were killed when working on

aerial cables because we heard about it from OSHA.

These two installers were installing all-dielectric self-supporting

aerial cables on poles. The hangers, however, were metal and over

six feet long. Both had attached the hangers to the poles, then

when installing the fiber cables had rotated the hangers enough

to contact high-voltage lines.

So even if the fiber is not conductive, fiber hardware can conduct

electricity or the installer can come in contact with live electrical

wires when working in proximity to AC power.

Fiber

Optic Installation Safety

Rules:

1. Keep all

food and beverages

out of the work area. If fiber particles are ingested they can

cause internal hemorrhaging

2. Wear disposable aprons to minimize fiber particles on your

clothing. Fiber particles on your clothing can later get into

food, drinks, and/or be ingested by other means.

3. Always wear safety glasses with side shields and protective

gloves. Treat fiber optic splinters the sarne as you would glass

splinters.

4. Never look directly into the end of fiber cables until you

are positive that there is no light source at the other end. Use

a fiber optic power meter to make certain the fiber is dark. When

using an optical tracer or continuity checker, look at the fiber

from an angle at least 6 inches away from your eye to determine

if the visible light is present..

5. Only work in well ventilated areas.

6. Contact wearers must not handle their lenses until they have

thoroughly washed their hands.

7. Do not touch your eyes while working with fiber optic systems

until they have been thoroughly washed.

8. Keep all combustible materials safely away from the curing

ovens.

9. Put all cut fiber pieces in a safe place.

10. Thoroughly clean your work area when you are done.

11. Do not smoke while working with fiber optic systems.

- SAFETY

NOTES

- Provided

by Leonard Wasser, Tool Pouch Training

-

- These are

the issues that need considering for working safely!

1.)

Most Frequent Industry

Recognized Safety Violations

a.) Improper drop bonding with power

b.) Poor workmanship

c.) Incomplete construction

2.)

Project Site Safety

a.) Material storage

b.) Parking

c.) Break areas

d.) Bathroom/cleanup facilities

e.) First aid equipment availability

f.) Work areas

g.) Power hazards

h.) Stray voltage possibilities

i.) Ladders

j.) Working in public access areas

3.) Outside Plant Safety

a.) Traffic/defensive driving

b.) Traffic control plan with permits where needed

c.) Power hazards

d.) Clearance issues when working and driving

e.) Off-road access issues

f.) Weather hazards

g.) Unsafe work areas (Including people)

h.) State mandated regulations (General Orders)

i.) Aerial construction issues

j.) Underground construction issues (800-USA DIG)

k.) Aerial lifts

l.) Ladders

m.) Working in public access areas

Download a safety poster from the FOA!

(C) 2002-10,

The Fiber Optic Association,

Inc.

Return To The

FOA

Home Page

Return To FOA

Tech Topics

Light in

the 1300-1550 nm range is unlikely to damage your retina, but might

harm the cornea or lens.

Light in

the 1300-1550 nm range is unlikely to damage your retina, but might

harm the cornea or lens.  The broken ends of fibers and scraps of fiber created during

termination and splicing can be extremely dangerous. The ends are

extremely sharp and can easily penetrate your skin. They invariably

break off and are very hard to find and remove. Sometimes a pair of

tweezers and perhaps a magnifying glass will get them out. Most of the

time, you have to wait to let them infect and work themselves out,

which can be painful!

The broken ends of fibers and scraps of fiber created during

termination and splicing can be extremely dangerous. The ends are

extremely sharp and can easily penetrate your skin. They invariably

break off and are very hard to find and remove. Sometimes a pair of

tweezers and perhaps a magnifying glass will get them out. Most of the

time, you have to wait to let them infect and work themselves out,

which can be painful!