|

Connector

and Splice Loss Testing

Note:

In

fiber optics, a single connector has no loss. The

"loss of a connector"

is defined as a "connection loss" caused by a mated

pair of connectors.

The lab method used to establish the average loss

value of a connector

design is shown below. The loss of connectors on a

patchcord or short

cable is given by FOTP-171 and the loss of an

installed cable

plant is measured by OFSTP-14 (MM) or OFSTP-7 (SM.)

In

order to establish a typical loss for connectors, it is

necessary to test all connectors in a standardized

fashion.

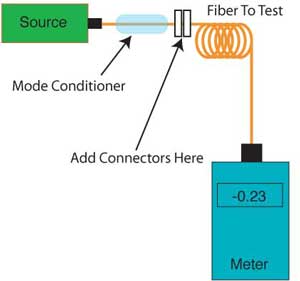

Measurements of

connector or splice losses are performed by measuring

the transmitted

power of a short length of cable and then inserting a

connector

pair or splice into the fiber and measuring the change

of loss as a

result of adding a connection. This test ( designated

FOTP-34

by the TIA) can be used for both multimode and

singlemode fiber,

but the results for multimode fiber are very dependent

on mode

power distribution.

FOTP-34

has three options in modal distribution: 1)EMD

(equilibrium

modal distribution or steady state) , 2) fully filled,

and 3) any

other conditions as long as they are specified. Besides

mode power

distribution factors, the uncertainty of the measured

loss is

a combination of , inherent fiber geometry variations,

installed

connector or splice characteristics, and the effects of

the splice bushing

used to align the two connectors.

This

test is repeated hundreds or thousands of times by each

connector or splice manufacturer, to produce data that

shows the repeatability

of their connector design, a critical factor in figuring

margins

for installations using many connectors. Thus loss is

not the

only criteria for a good connector, it must be

repeatable, so

its average loss can be used for these margin

calculations with

some degree of confidence.

Connector

and Splice Durability

Another

factor important to a connector is the durability of

the design, shown by its ability to withstand many

matings without

degradation in loss. Testing connector durability is

simply a

matter of repeated mating and demating of a connector

pair while

measuring loss. Since the loss is a function of both

connectors

and alignment sleeve, it is helpful to determine which

are the

contributors to degradation. Plastic alignment sleeves,

when used

with ceramic connectors, for example,will usually wear

out much

faster, shaving plastic off onto the connector ferrules

and causing

increased loss and return loss. When testing durability,

periodic

inspection of the connector end faces and ferrules with

a microscope

to determine wear or contamination is very important.

Splice

durability is one of withstanding many cycles of

environmental

stress, since splices are often used in splice

enclosures in pedestals

or mounted on poles where they are exposed to the

extremes of

climatic changes. Manufacturers usually test a number of

splices

through many environmental cycles and accelerated aging

to determine

their durability. Such tests may take years.

Connector

Reflectance

If

you have ever looked at a fiber optic connector on an

OTDR,

you are familiar with the characteristic spike that

shows where

the connector is. That spike is a measure of the

reflectance

(sometimes also called optical return loss) of the

connector, the names used for the amount of light

that is reflected back up the fiber by light reflections

off the

interface of the polished end surface of the connector

and air.

It is also called fresnel reflection and is caused by

the light going

through the change in index of refraction at the

interface between

the fiber (n=1.5) and air (n=1).

That

return spike is one component of

the connector's loss, representing about 0.3 dB loss for

a non-contact or air-gap connector (two air/glass

interfaces at 4% reflection each), the minimum loss for

non-contacting

connectors without an index-matching fluid. But in

high-bit rate

singlemode systems, that reflection can be a major

source of bit-error

rate problems. In some singlemode systems, the reflected

light interferes with the laser diode transmitter,

causes mode-hopping and can be a source of noise.

Minimizing

the light reflected back into the laser is necessary to

get maximum

performance out of high bit rate laser systems,

especially the

AM modulated CATV systems. In multimode systems,

reflections can add to background noise in the

fiber.

Since

this is more a problem with singlemode systems,

manufacturers

have concentrated on solving the problem for their

singlemode

components but multimode connectors benefit also.

Several schemes have

been used to reduce reflectance, mainly reducing the gap

between

connectors to a few wavelengths

of light using a physical contact (PC) polish on the end

of the

connector ferrule, which reduces the fresnel reflection.

The usual

technique

involves polishing the end surface of the fiber to a

convex surface

or at a slight angle to prevent direct back reflections.

Another, even more effective solution, is to

polish the end of the singlemode

connector ferrule at a small angle (about 8 degrees) to

cause any

reflected light to be absorbed in the fiber cladding.

These are

called angle-polish connectors (APC) and are widely used

for CATV and

high big rate digital systems.

More

on different methods of reflectance testing.

|