|

Insertion

Loss

Testing the Installed Fiber Optic Cable Plant With A Test Source and Power Meter

Typical

fiber optic cable plants are composed of a backbone cable

connecting patch panels and several short jumper cables

which connect the equipment onto the cable plant. Premises

cabling systems look like the photo to the right,

where the backbone fiber is terminated in wiring closets and

short jumpers connect wall outlets or directly to the

equipment. These installations often have no splices at all,

since distances are short. Premises cabling, which is short

and often lower speed, is often multimode fiber, unless the

network speed is >10Gb/s as in data

centers, uses a GPON

passive optical LAN or is shared with a cellular

distributed antenna system. Typical

fiber optic cable plants are composed of a backbone cable

connecting patch panels and several short jumper cables

which connect the equipment onto the cable plant. Premises

cabling systems look like the photo to the right,

where the backbone fiber is terminated in wiring closets and

short jumpers connect wall outlets or directly to the

equipment. These installations often have no splices at all,

since distances are short. Premises cabling, which is short

and often lower speed, is often multimode fiber, unless the

network speed is >10Gb/s as in data

centers, uses a GPON

passive optical LAN or is shared with a cellular

distributed antenna system.

OSP (outside plant) cable plants look similar, but the the fiber is all

singlemode and cable runs may be long, requiring splices

every 2-4 km. In addition, the fibers are not terminated

directly, but high quality factory made pigtails are spliced

onto the backbone cable. The process of testing any fiber

optic cable plant during and after installation includes all

the procedures covered so far.

To

thoroughly test the cable plant, one needs to test it three

times, a continuity test of the fiber optic cable on the

reel before installation, insertion loss of each installed

segment and complete end to end loss. One should test the

cable on the reel for continuity before installing it, to

insure no damage was done in shipment from the manufacturer

to the job site. Since the cost of installation usually is

high, often higher than the cost of materials, it only makes

sense to insure that one does not install bad cable. It is

generally sufficient to just test continuity, since most

fiber is installed without connectors and then terminated in

place, and connectors are the most likely problem to be

uncovered by testing for loss. However, if any damage is

visible on cable reels, OTDR testing may be needed to verify

the cable is still good.

After

installation and termination, each segment of the cable

plant should be tested individually as it is installed, to

insure each connector and cable is good. Finally each end to

end run (from equipment placed on the cable plant to

equipment) should be tested as a final check. Measured loss

should be compared to the calculated

loss budget for the cable plant to determine if the

measured loss is acceptable.

What

is Insertion Loss?

Optical

loss is a term used in many contexts in fiber optics. It

simply means a reduction in optical power, for example the

loss caused by a component or an entire cable. The

component could be a length of fiber, a splice, a

connection made between two connectors or a passive

component like an attenuator, splitter or switch. The

cable could be a patchcord or an installed cable plant.

The

primary test for these is an insertion loss test, test

that uses a test source and optical power meter to measure

the difference in power when the component is inserted in

the test setup. For a cable plant, the insertion loss test

uses a test source and power meter to simulate the

transmitter and receiver of a communications link.

Variations of this test are used for practically every

loss test in fiber optics.

Optical

loss in a fiber optic link. The meter shows the decrease in

optical power in the pulse as it traverses the fiber.

The goal of an insertion loss test is to simulate link

operating conditions by using a test source to launch power

into the fiber or cable under test and a power meter to

measure the loss at the other end. That requires creating

launch conditions from the test source that are similar to

transmitter sources and using the power meter to measure the

power from the source before and after the component or

cable is inserted in the test setup. How this is done is the

subject of many standards in fiber optics that ensure the

test results from laboratories, manufacturers, installers or

users are comparable.

Why

is this test called an "insertion loss" test?

The name comes from the fact that one performs the test by

inserting the components under test between a test source

and a power meter. The most obvious version of this test is

the method used by manufacturers to evaluate connector or

splice loss as shown in the diagram below. It can also be

used to measure the attenuation of optical fiber.

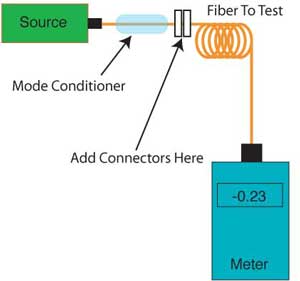

Insertion

loss test for a fiber optic connector.

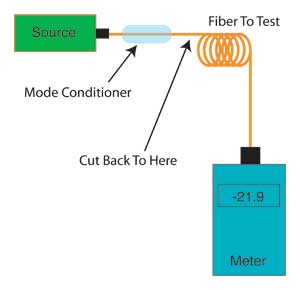

Cutback

test to measure the attenuation coefficient of optical

fiber.

This is the insertion loss test used by manufacturers for

evaluating the performance of connectors or splices. This

test connects the test source to a power meter over an

optical fiber. Often this test is done with bare optical

fiber with the connection to the power meter using a bare

fiber adapter. The meter and source are turned on and a "0

dB" reference is set.

To test the component the fiber is cut and a pair of

connectors or a splice is inserted in the fiber and the

change in power measured. The change in power indicates the

loss generated by the insertion of the component. When

evaluating a new component, manufacturers may do hundreds or

thousands of these tests to determine the average

performance of the component that they specify in their

product datasheets.

For tests involving multimode fiber, the test results are

highly dependent on the test setup, particularly the modal

distribution launched into the fiber used in the test. Test

sources can have significant variations in modal

distribution so it is important to include some form of

modal conditioning in the test fiber. Modal conditioning and

other issues that affect all multimode tests will be covered

in a section below on test conditions.

Note: It Is Connection Loss, Not Connector Loss. It's common in fiber optics to talk about

the loss of a connector, but a connector loss is measured

when mated to another connector. In fact, a single

connector has no loss because a connector is defined as a

component that allows making connections between two

fibers or connects one fiber to an active device like a

transmitter or receiver. The correct term is "connection

loss" because it is the loss of a mated pair of

connectors. In practice, we assign a loss to a connector

by testing it against a reference connector, as you will

see when we discuss single-ended insertion loss testing

below.

Testing Cables And Cable Plants With Connectors

The most common tests involve testing fiber optic cable

plants, patchcords and other components that have connectors

on each end. These are tested with a test source and power

meter with reference test cables to connect to the component

under test. There are two versions of this test, a double

ended test and a single ended test.

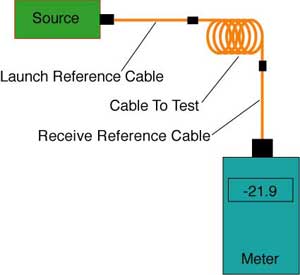

The double-ended test is the standard test for installed

cable plants that allows testing the entire cable plant

including the connectors on each end. It is a simulation of

the loss an actual transmission system will see when

connected to the cable with patchcords. Here is the block

diagram of the test:

Standard cable plant test, double-ended with launch and

receive cables

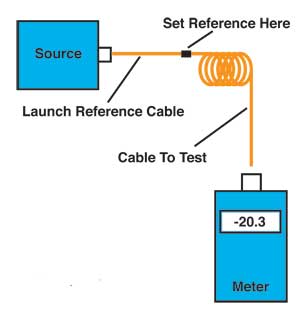

The source has a launch reference cable because it launches

power into the component under test. The power meter has a

receive reference cable because it receives the power after

the component has been inserted. Each of these mate to one

end of the cable under test to measure the connection loss

on both ends, hence the name "double-ended." The

cable under test is sometimes called the "permanent link," a

reference to the name of the installed cable in UTP copper

cable testing.

The "0 dB" reference measurement is made with the test

source and power meter with their reference cables using one

of three different but acceptable methods, depending on the

types of connectors on the test equipment and the cable

plant. The

reason for the existence of three methods is the

compatibility of test equipment to the cable plant; whether

the test equipment has connector interfaces that allow

direct connection to the cable under test.

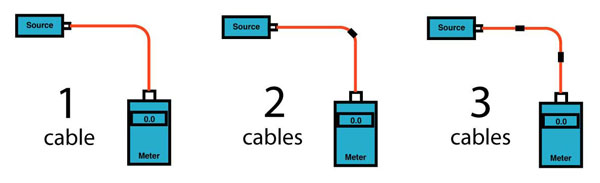

Three ways to set a "0dB" reference for insertion loss

testing.

Which

method is used depends on the connectors on the cable plant

you are testing and the connector interfaces on your test

equipment. (And some history about how different companies

defined testing.)

The

options for use of these three methods are:

- If

the test equipment has connectors compatible with the

cable plant, a one-cable method can be used.

- If

the test equipment does not have connectors compatible

with the cable plant, a two- or three-cable method must

be used.

- If

the test equipment does not have connectors compatible

with the cable plant and/or the connectors are the “plug

and jack” or “male, female” type like the MPO multifiber connector, a three-cable method

must be used.

The insertion loss test then measures the loss generated by

adding the cable under test. The value measured is called

the loss of that particular fiber optic cable. The loss can

be compared to the calculated

loss budget to see if the cable plant meets

specification.

Testing

the complete cable plant is done per standard test

procedures, e.g. FOA

Standard FOA-1, TIA OFSTP-14 for multimode fiber or

OFSTP-7 for singlemode, which use the same procedures or

ISO/IEC 61280, ISO/IEC 14763, etc. These

standards offer 3 different ways to set a "0 dB"

reference and cover the peculiarities of multimode

fiber in detail. Information for multimode cables covers

the problems of controlling

mode power distribution, but the same procedures

apply for singlemode fiber, less the concerns expressed

for mode power distribution errors.

For

multimode fibers, testing is now usually done at 850 and

sometimes also at 1300 nm, using LED sources with some

control over mode power distribution. This will prove the

performance of the cable for every datacom system,

including FDDI and ESCON, and meet the requirements of all

network vendors.

OFSTP-7

was written for singlemode fiber cables. Testing is

usually done at 1310 and 1550 nm, but 1625 nm is sometimes

required also. The1550 nm testing will show that the cable

can support wavelength division multiplexing (WDM) at 1300

and 1550 nm for future service expansion. In addition,

1550 and 1625 nm testing can show microbending losses that

will not be obvious at 1300 nm, since the fibers are much

more sensitive to bending losses at the longer

wavelengths.

If

cable plant end to end loss exceeds total allowable loss,

the best solution is to retest each segment of the cable

plant separately, checking suspect cables each way, since

the most likely problem is a single bad connector or

splice. If the cable plant is long enough, an OTDR may be

used to find the problem. Bad connectors must then be

repolished or replaced to get the loss within acceptable

ranges.

Testing Patchcords

One can also do a variation of the insertion loss test with

only a launch cable, called a "single ended" test, that only

tests the connector on the source end of the cable. This

test is often used to test patchcords since it allows the

measurement of the connectors on each end separately, a more

rigorous method of testing these short cables.

Fiber optic patchcord test, also called "single-ended" test

The single ended test looks like the double ended test

except there is no receive reference cable. The cable under

test is mated to the connector on the launch cable and the

power meter. The "0 dB" reference measurement is made with

the test source, a launch reference cable and the power

meter, exactly like the one cable reference for double ended

insertion loss tests.

The output of the launch cable is the 0 dB loss reference,

so for short cables like patchcords, the measurement is

basically the loss of the connection between the launch

cable and the test cable. The test cable can be reversed and

the connector on the other end tested separately. This test

is used on patchcords because it allows testing each

connector individually, ensuring that both connectors meet

specifications. If the cable were tested with the double

ended test, one would measure a total loss of both

connectors and could not identify if one connector were out

of specification.

Choosing Appropriate Test Equipment

In order to perform an insertion loss test, it is necessary

to have appropriate equipment for the cables or cable plant

under test. Whether one uses a test source and power meter

or optical loss test set (OLTS), the equipment must be

compatible with the test requirements.

The fiber optic power meter used for insertion loss testing

should be calibrated at the wavelength of the test source

being used. The meter should have a connector adapter

compatible with the connectors on the cable plant being

tested. Having a special "dB" range that will allow setting

a "0 dB" loss reference power level will simplify testing.

An OLTS will offer both source and power meter for loss

testing at the appropriate wavelengths. The requirements for

the source for modal conditioning (see below) and

compatibility of the instrument to the connectors on the

cable plant being tested may have to be accommodated by the

reference test cables.

Test Source Wavelengths

For multimode fiber, the test source should be a LED at 850

nm that is the wavelength used for virtually all multimode

communications systems. There is an option for testing at

1300 nm with a LED also, but there are few systems today

that operate at that wavelength so testing at that

wavelength is generally unnecessary. You will find some

references to using 1300 nm testing to find stress on the

cable, since multimode fiber is much more sensitive to

bending losses at 1300 nm. But even that reason is no longer

relevant in most cases because most multimode fiber is of

the bend-insensitive (BI) type. Finding stress areas in

cables can be tricky anyway, but if the cable is long

enough, an OTDR that offers both 850 and 1300 nm testing is

a better instrument for finding the location of the loss.

While most 850 nm multimode systems operating over OM3 or

OM4 fiber today use VCSEL sources (vertical cavity

surface-emitting lasers), these sources are not recommended

for use as test sources due to the unpredictable mode power

distribution of individual devices. Instead, standards now

call for sources with mode power distribution or

conditioning the output of the source and its launch cable

to approximate an ideal VCSEL mode condition. This will be

covered below in reference cables and again in the section

on mode conditioning for multimode fiber testing.

Singlemode fiber is tested with laser sources, similar to

the devices that will be used in the communications systems

which operate over the fiber. Singlemode fiber will be

tested with 1310 nm and/or 1550 nm lasers depending on the

cable plant to be tested. Short links, from hundreds of

meters in a data center or building up to 20 or 30 km in

metro networks, are always tested at 1310 nm and often at

1550 nm if wavelength division multiplexing (WDM) or passive

optical networks (PONs) like FTTH are planned for use on the

link. Long links are tested at 1550 nm to match the

wavelengths of networks using them.

There may also be a reason to test short singlemode links at

1550 nm to find stress loss in a cable plant caused by

installation. But as mentioned above, this is not relevant

if bend-insensitive fiber is being used in the link, common

today in high fiber density cables. Also testing at 1550 nm

for finding stress is more relevant to ODTR testing where

the cause of the stress loss can be determined.

Reference Test Cables

Just as important as the choice of test equipment is the

choice of reference

test cables for the launch cable and receive cable.

The basic requirements for test cables is that they be about

1 to 2 meters long, match the size of fiber in the cable

plant under test and have connectors compatible to the

connectors on the cable plant. Multimode graded index fiber

in test cables should be 62.5/125 for OM1 cable plants or

50/125 for OM2, OM3, OM4 or OM5 fiber cable plants. There

are no significant differences in types of 50/125 fiber so

any type of this size fiber can be used to test any other

type. Today most of the multimode graded index fiber is bend

insensitive (BI) fiber. Many standards recommend not using

BI fiber for reference test cables even if testing BI fiber

cables, but this may not be possible. We'll discuss BI fiber

in the section on modal conditioning for multimode

fiber. When testing step-index multimode cable plants

using plastic optical fiber (POF) or plastic coated silica

fiber (PCS), one must likewise choose a matching fiber for

reference cables.

The connectors on the test cables should be PC polished

(physical contact) and should be of very high quality,

determined by having low loss when tested against each other

in the single ended test mode. One should use low loss

patchcords, typically under 0.3 dB, so the test results will

be consistent. With use, the connectors will wear, even when

cleaned frequently. If the patchcords exceed 0.5 dB over

time, they should be replaced. Careful repolishing with

diamond polishing film by an experienced tech may bring the

loss back down. Or the cables should be replaced.

The new TIA OFSTP-14 and ISO/IEC 61280-4-1 standards for

multimode call for 2 meter long "reference quality" test

cables with connector loss of 0.1 dB. The standard explains

that this may require special cables with selected fibers

and selected connectors as well as higher quality mating

adapters such as those used for singlemode fiber with

ceramic mating adapters. For singlemode fiber the loss

specified is 0.2 dB.

There are very few sources of "reference quality" test

cables. Multimode cables with losses of 0.1 dB will degrade

with use, showing the effects of the many mating cycles

required when testing in the field. Using high quality

cables with relatively loss is the practical solution.

Cables with loss of 0.2 up to 0.5 dB maximum are generally

adequate for testing multimode fiber.

The launch reference cable combines with the test source to

create the modal conditions used for testing. If the source

modal conditions are not specified, and they rarely are, the

modal conditions can be modified by the user using special

patchcords or modal conditioning on the cable itself. This

is discussed in the section on modal conditioning below. Do

not ignore modal conditioning in multimode testing. When

coupled into multimode fiber, LEDs typically have higher

modes than are specified by test standards. Mode

conditioning will remove those higher modes and tests will

be more consistent and will consistently show lower loss.

Singlemode reference cables should also be high quality

cables. The connectors must also be compatible to the type

of connector on the cable plant being tested, e.g. PC

(physical contact, color coded blue) or APC (angled physical

contact, color coded green.) For singlemode fiber "reference

quality" test cables, the loss specified is 0.2 dB. High

quality singlemode patchcords should be 0.3 dB or less so

this limit is not unreasonable.

Singlemode does not have mode conditioning standards like

multimode fiber, but short launch patchcords connected to a

typical laser source may support 2 modes for short distances

and that can affect measurement results. To ensure the

launch is singlemode, a mode filter made with a small loop

of fiber 40 to 60 mm diameter (1.6 to 2.4 inches) in the

launch cable will ensure singlemode launching at the end of

the cable.

More on reference cables.

Test Conditions For Accurate Insertion Loss Testing

As with any testing, to reduce measurement uncertainty, it

is important to consider and as, far as possible, control

test conditions. It is important to understand all the

contributions to measurement uncertainty and how their

effects can be minimized by the test operator. Many sources

of measurement errors are not controllable by the user. They

depend on the manufacturer of the test equipment, optical

fiber, connectors, etc. and their quality control.

The first and most important issue is to decide which

reference method to use (1, 2 or 3 cables) and record that

with the test data. Since the test results change

considerably with the choice of reference method, this is

very important information to record. After setting the "0

dB" reference, it is important to not disconnect the

reference launch cable from the source. The connection

between the source and cable can change if it is

disconnected and reconnected invalidating the "0 dB"

reference set.

Secondly, monitor the type and condition of all the test

reference cables. This is probably the biggest cause of

random errors in testing. Of course the fiber in the

reference cables must match the type in the cables being

tested and the connectors must be compatible. The condition

of the connectors on the reference cables should be

inspected for cleanliness and damage, cleaned and inspected

again to ensure proper cleaning. Then the reference cable

connectors should be tested against each other to ensure

they are still low loss. As the loss increases from more

testing, replace the cables or refurbish the connectors by

repolishing using diamond film.

The connections to test cables have another important

component, the mating adapter used with connectors. All the

single fiber connectors use mating adapters to align the

ferrules. These adapters are available in several types,

depending on the alignment sleeve for the ferrules. Some

inexpensive mating adapters use plastic alignment sleeves

that should never be used for testing. These sleeves wear

out quickly and leave dust and residue on the connectors.

The acceptable mating adapters use metal or ceramic

alignment sleeves. Metal sleeves work for hundreds of tests

but ceramic sleeves will last many times longer and leave no

residue.

Test equipment used for insertion loss testing should be

checked and power meters calibrated regularly, according to

manufacturers specifications. When making tests, the biggest

problems are with sources. First of all, the source needs to

be stable; if its output power drifts, the 0 dB reference

will be lost and all tests will be wrong. You can test your

own source by connecting it to a meter with a patchcord and

turning it on. Note how long it takes the output to be

stable and use that time as a warmup time when setting up to

make tests. If the source is not stable over time, varying

more than 0.1 dB after warmup, it should be checked or

replaced with a more stable source.

The second issue with sources is modal

conditioning. This is mainly a multimode fiber and LED

test source problem, but even single mode sources with

lasers can have modal problems. The user should ensure that

multimode launch cables have proper mode power distribution

since that can affect the loss measured significantly. Using

a simple mandrel wrap and checking the modal distribution

with a HOML (higher

order mode loss) test as described below will greatly reduce

measurement errors. For singlemode fiber, a simple loop mode

filter is all that is needed. With all reference cables, be

careful to not stress them during the tests as that can

induce loss that will change the 0 dB reference and or

create changes in the modal distribution.

The technician performing the tests should be experienced in

the process, familiar with the procedures and conduct every

test in the same manner. Even small issues like stress on

reference cables can make big differences in measurements.

If reasonable precautions are taken, what is the likely

accuracy of loss measurements? Experience has shown that

typical measurements have an uncertainty of approximately

+/-10% of the measured value in dB. Thus a 2dB loss has an

estimated uncertainty of +/-0.2 dB.

Troubleshooting Hints

Most problems with high cable loss are caused by bad or

dirty connectors, high loss splices or stress loss in the

cable caused during installation.

The first step is connectors should be inspected with a

microscope for dirt, scratches cracks, or other damage and

thoroughly cleaned. Visual fault locators can check for

continuity, proper connections and, if the cable jacket

permits, high loss bends or breaks.

If you have high loss in a single cable with connectors on

each end, you can reverse it and test in the opposite

direction using the single-ended test method. Since the

single ended test only tests the connector on the end

connected to the launch cable, you can isolate a bad

connector this way. The bad connector is the one at the end

mated to the launch cable when you measure high loss.

High loss in the double-ended test should be isolated by

retesting single-ended and reversing the direction of test

to see if the end connector is bad. If the loss is the same,

you need to either test each segment separately to isolate

the bad segment or, if it is long enough, use an OTDR.

What

About OTDR Testing?

The OTDR is better at troubleshooting problems than making

quantitative measurements because it uses a different test

method. However it can be invaluable at testing in certain

situations and troubleshooting. Read

more about OTDRs here.

This page was taken from the FOA

Guide To Fiber Optic Testing, Chapter 8.

Recommended

reading:

FOA

Standard FOA-1

Reference Cables.

5

Ways to test a fiber optic cable, 3 different ways to

set a "0 dB" reference

Testing

cables with different types of connectors

Accurately

Testing Fiber Optic Cables

The

Math of Insertion Loss Testing - Reference Methods

More

on OLTS/OTDR testing.

Videos

on cable testing on the FOA Channel on

|