Fusion Splicing

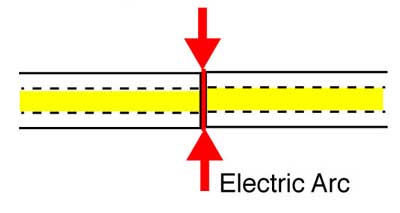

Fusion splicing is the process of fusing or welding two

fibers together usually by an electric arc. Fusion

splicing is the most widely used method of splicing as it

provides for the lowest loss and least reflectance, as

well as providing the strongest and most reliable joint

between two fibers.

Virtually all singlemode splices are fusion. Multimode

fibers can be harder to fusion splice as the larger core

with many layers of glass that produces the graded-index

profile are sometimes harder to match up, especially with

fibers of different types or manufacturers.

Fusion splicing may be done one fiber at a time or a

complete fiber ribbon from ribbon cable at one time. First

we'll look at single fiber splicing and then ribbon

splicing.

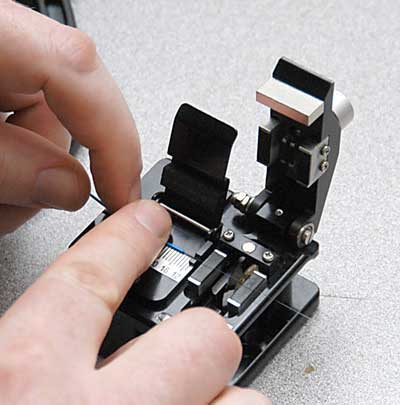

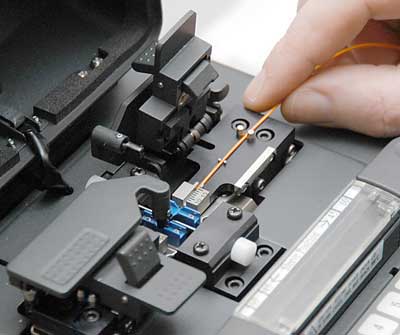

Fusion splicing machines are mostly automated tools that

require you preset the splicing parameters or choose

factory recommended settings that will control the

splicing process itself. All require the use of a

precision fiber cleaver that scribes and breaks (cleaves)

the fibers to be spliced precisely, as the quality of the

splice will depend on the quality of the cleave. Most

splicing machines come with a recommended cleaver.

Proper use of both the splicing machine and the cleaver

require carefully following the manufacturer's directions.

Each manufacturer's product is slightly different and

requires somewhat different procedures. Reading the

manuals and practice with the machine are important,

especially if the operator has not been trained on the

particular splicer in use.

Automatic Fiber Alignment

The ends of the fibers are on moveable stages which are

used to align the fibers and set the end gap

automatically. During the automated process, the splicer

will align the fibers using one of two methods:

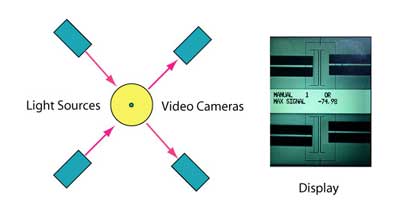

Optical Core or Profile Alignment Systems (PAS)

Optical Core Alignment (also called “Profile

Alignment”), an optical alignment technique, is used by

many models of fusion splicers. The two fibers are

illuminated from two directions, 90 degrees apart. From

the images in a video camera, software recognizes the core

of the fibers and aligns them automatically using movable

stages. The software also estimates splice loss after the

fusion splicing is complete. Ribbon splicers typically use

profile alignment.

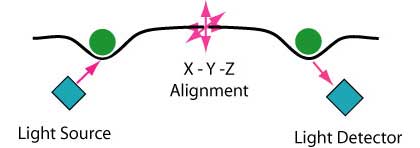

Local Injection and Detection (LID System)

LID Core Alignment uses “Local Injection and Detection” of

light. Light is coupled into the fiber by bending the

fiber and shining a light source (LED or laser) on the

outside of one fiber, so some light is coupled into the

core. On the other fiber, the bend causes macrobending

losses that are measured by a photodetector, providing a

relative indication of light transmission through the

splice. The splicer measures light coupling through fiber

while moving fibers on actuators to get best transmission

which means the fibers are optimally aligned. The LID

system also checks transmission after splicing to estimate

splice loss.

Both techniques work well with most fibers. Refer to the

instruction manual or ask the manufacturer is there is any

question about using the splicer with the fiber you are

installing.

Splicing machines also generally have a heating device for

heat shrinking a protective sleeve over the finished

splice to protect it from moisture or other environmental

hazards. An alternate method using clamp-on protectors.

In addition to the splicer and cleaver, the tech doing the

splicing will need a set of cable preparation and fiber

stripping tools. Since much fusion splicing is done in the

outside plant, the splicing tech should have tools to

handle all types of loose tube cable, both gel-filled and

dry water-blocked, with various jacket styles, armor, etc.

Fusion splicing requires stripping a longer length of bare

fiber than termination, so the choice of stripper is

important. There are three types of fiber strippers

available, known as (from Left) the Miller Stripper,

No-Nik and Micro-Strip. All three can work equally well,

and most techs choose the one they are most familiar with.

The Miller, perhaps the most rugged, has the disadvantage

of being "right-handed." The Micro-Strip allows setting

strip length for consistent strips. The No-Nik is careful

with the fiber but requires careful cleaning. Most

strippers are "sized" for the fiber coatings to be

removed, so ensure you have the proper stripper for the

fiber being stripped. Whichever stripper is used, care

must be taken to not nick the fiber during the stripping

process as it can cause cracks that may lead to fiber

failure sometime in the future. Strippers require careful

cleaning and immediate replacement if they become damaged

or worn.

The Fusion Splicing Process

(VHO

on cable preparation)

Detailed

Instructions For Fusion Splicing With EasySplicer

Prepare the cables to be spliced

Strip jacket, removing an adequate amount of jacket,

usually 2-3 m, for splicing and dressing the buffer tubes

and fibers in the splice closure. Leave the proper amount

of strength members to attach the cable to the closure.

Refer to the splice closure directions for lengths needed.

Clean all water-blocking materials using appropriate

cleaners.

Remove buffer tubes exposing fibers for splicing.

Generally splice closures will require ~1 m buffer tubes

inside the closure to and ~ 1 m fiber inside the splice

tray. Clean all water-blocking materials.

Prepare the fibers to be spliced

The process is the same for all splice types: strip, clean

& cleave.

Each fiber must be cleaned thoroughly before stripping for

splicing.

When ready to splice a fiber, strip off the buffer

coating(s) to expose the proper length of bare fiber

Clean the fiber with appropriate wipes

Cleave the fiber using the process appropriate to the

cleaver being used

Place the fiber into the guides in the fusion splicing

machine and clamp it in place

Repeat for the other fiber to be spliced

Running the splicer program

Choose the proper program for fusion splicing the fiber

types being spliced

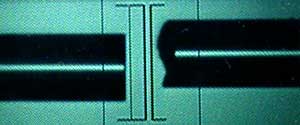

The splicer will show the fibers being spliced on the

video screen.

Fiber ends will be inspected for proper cleaves and bad

ones like the one on the right above will be rejected.

Automated Splicing

Fibers will be moved into position

Prefuse cycle will remove any dirt on the fiber ends and

preheat the fibers for splicing

The fibers will be aligned using core alignment method for

that splicer

The fibers will be fused by an automatic arc cycle that

heats them in an electric arc and feeds the fibers

together at a controlled rate

When fusion is completed, the splicing machine will

inspect the splice and estimate the optical loss of the

splice. It will tell the operator if a splice needs to be

remade.

The operator will remove the fibers from the guides and

attach a permanent splice protector by heat-shrinking or

clamping clam shell protectors.

Evaluating Splices

Modern splicing machines do all the splice processes

automatically, so the information below is for

information only. It is unlikely that an automatic

fusion splicing machine would show any of the problems

that were common with manual fusion splicers in the

past.

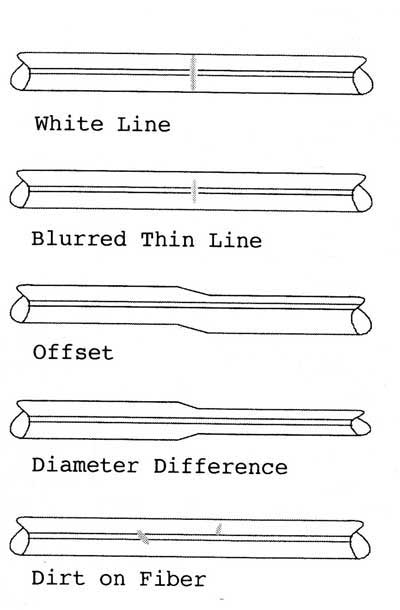

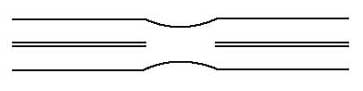

Good Splices

Visually inspect splice after the program has run,

using both X and Y views. Some flaws that do not

affect optical transmission are acceptable, as shown. Some

fibers (e.g. fluorine-doped or titanium coated) may cause

white or black lines in splice region that are not faults.

(Graphic from Sumitomo manual)

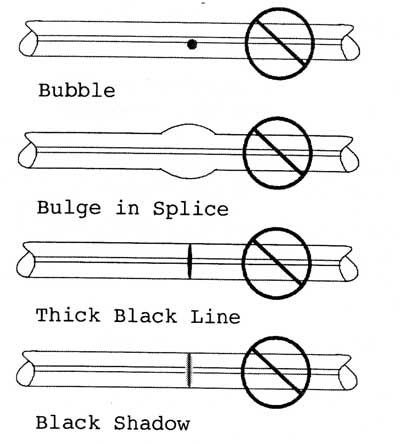

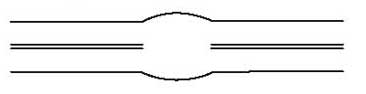

Bad Splices

Some flaws are unacceptable and require starting the

splicing process over. Some, like black spots or lines,

can be improved by repeating the ARC step, but never more

than twice. For large core offsets, bubbles or bulging

splices, always redo. (Graphic from Sumitomo manual)

Splice Problem Troubleshooting

Here are some common problems and likely causes.

Not Fused Through

Fusion current too low

Prefusion time too short

Matchheads

Contaminated electrodes

Fusion current much too high

Prefusion time much too long

Prefusion current much too high

Autofeed too small

Gap too large

Constriction

Current too high

Feed rate too slow

Prefusion time too long

Prefusion current too high

Gap too wide

Contaminated electrodes

Enlargement

Autofeed too fast

Incorrect current

Bubble or Inclusion

Contaminated fiber end faces

Poor cleave

Fusion current too high

Prefusion current or time too low

Additional Problems

Fusion splicers generally have stored programs for most

fibers and the user can modify those program parameters or

create new ones. Refer to the instruction manual or ask

the manufacturer is there is any question about using the

splicer with the fiber you are installing.

It is sometimes necesary to splice older fibers, either in

restoration or modifying networks. Older fibers may become

brittle and hard to strip

Splice Closures

After fibers are spliced, they will be placed in a splice

tray which is then placed in an splice closure. Outside

plant closures will be carefully sealed to prevent

moisture damage to the splices. The closure placed in

a designated protected place to complete the installation.

All cables that contain metallic elements like armor or

strength members must be grounded and bonded at each

splice point. Closures are designed to clamp cable

strength members to provide strength to prevent pulling

the cable out and seals to prevent moisture damage to the

splices.

Testing

Fusion splicers are used to create long cable lengths by

splicing multiple cable segments. Although the splicer

will give an estimate of the splice loss, the only way to

test it is with an OTDR.

Since OTDRs have directional errors, testing may be

required from both directions and averaged. Generally long

concatenated cables are tested with an OTDR and traces

kept for documentation in case of restoration.

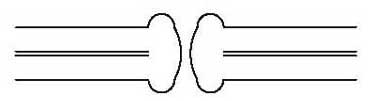

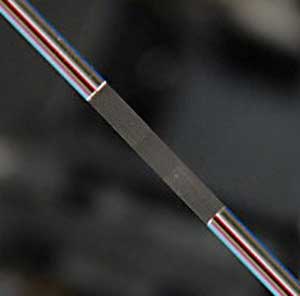

Ribbon Splicing (Mass Fusion Splicing)

Many high fiber count cables today are made from ribbons

of fibers, usually 12 fibers per ribbon. Splitting all

those fibers out to splice individually would be time

consuming, so ribbon fusion splicers, also called mass

fusion splicers, can splice entire ribbons at one time,

creating a splice that looks like this.

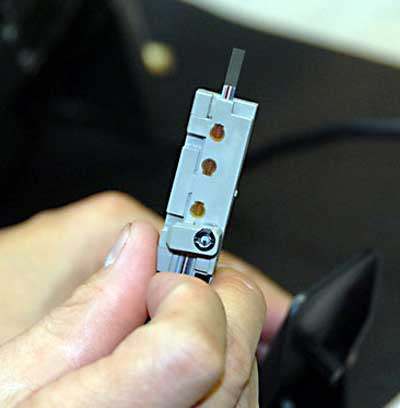

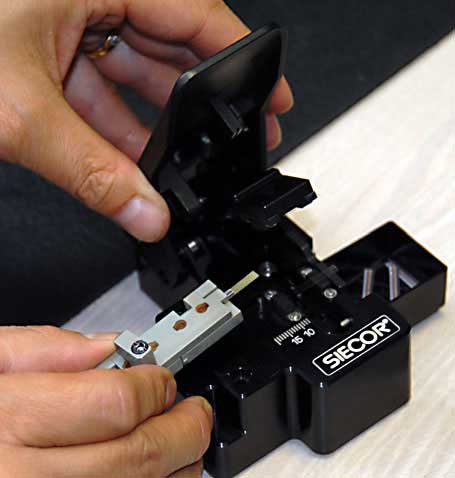

Ribbon splicers look similar to single fiber splicers and

work in much the same way, except the ribbons are treated

as one assembly, stripped, cleaved and spliced by special

tools while held in a special holder.

Below is the special holder used by the Corning ribbon

splicer shown.

The holder is inserted in a special stripper that uses

heat to make stripping easier.

After stripping, the holder is placed in a special cleaver

that will cleave all 12 fibers at once.

The fixture with all the cleaved fibers is placed in the

splicing machine.

When the second ribbon is prepared, the unit is set for

automated splicing. The splices are shown being made

below.

Fusion Splicer Maintenance

All fusion splicers have maintenance requirements which

should be described in the operating manual. Besides

cleaning regularly, they require electrode alignment and

occasional replacement. Follow manufacturer's requirements

for servicing.

Virtual

Hands On, Fusion Splicing

Virtual

Hands On, Ribbon Splicing

Detailed

Instructions For Fusion Splicing With EasySplicer

Table of Contents: The FOA

Reference Guide To Fiber Optics

|