Topic: Fiber Optic Terminations |

Table of Contents: The FOA Reference Guide To Fiber Optics |

Fiber Optic Terminations |

| ST

(an AT&T Trademark) is the one of the most

popular connectors for multimode networks,

like most buildings and campuses. It has a

bayonet mount and a long cylindrical ferrule

to hold the fiber. Most ferrules are ceramic,

but some are metal or plastic. And because

they are spring-loaded, you have to make sure

they are seated properly. If you have high

loss, reconnect them to see if it makes a

difference.STs are being replaced by SCs. |

|

| FC/PC was one of the most popular singlemode connectors for many years. It screws on firmly, but make sure you have the key aligned in the slot properly before tightening. It's being replaced by SCs and LCs. |  |

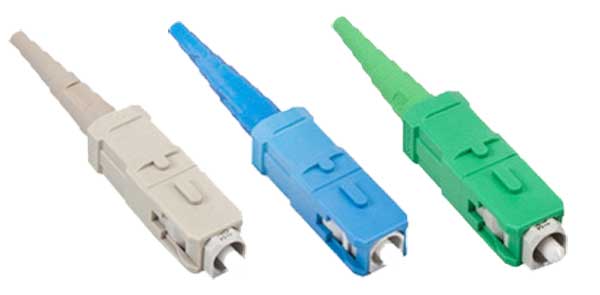

| SC is a snap-in connector that is widely used in singlemode systems for it's excellent performance and multimode systems because it was the first connector chosen as the standard connector for TIA-568 (now any connector with a FOCIS standard is acceptable.) It's a snap-in connector that latches with a simple push-pull motion. It is also available in a duplex configuration. |  |

| The

ST/SC/FC/FDDI/ESON connectors have the same

ferrule size - 2.5 mm or about 0.1 inch - so

they can be mixed and matched to each other

using hybrid mating adapters. This makes it

convenient to test, since you can have a set

of multimode reference test cables with ST or

SC connectors and adapt to all these

connectors. |

From the top: ST>FC SC>FC SC>ST |

| In

the late 1990s a number of miniature connectors (called "small form

factor connectors")were introduced to allow higher density in patch

panels and smaller transceivers. Of these only one, the LC shown here,

gained wide acceptance and the MU (shown below) has been used in some

areas. LC uses a 1.25 mm ferrule, half the size of the ST. Otherwise, it's a standard ceramic ferrule connector, easily terminated with any adhesive. Good performance, highly favored for singlemode and the connector of choice for multimode transceivers for gigabit speeds and above, including multimode Ethernet and Fibre Channel. |

|

| In 2020 several new connectors were introduced tomake

a smaller duplex connector than even the duplex LC. The three

connectors used LC 1.25mm ferrules but in a single connector body. One

manufacturer introduced both horizontal and vertical versions, while a

second manufacturer only offered a vertical version. |

Comparison of SENKO CS (L) and SN (R) connectors with duplex LC.  US Conec MDC connector. |

| The

3 small form factor connectors below (MT-RJ, Opti-Jack and Volition)

never became accepted in the market and are basically obsolete. MT-RJ is a duplex connector with both fibers in a single polymer ferrule. It uses pins for alignment and has male and female versions. Multimode only, field terminated only by prepolished/splice method. Basically obsolete. |

|

| Opti-Jack is a neat, rugged duplex connector cleverly designed around two ST-type ferrules in a package the size of a RJ-45. It has male and female (plug and jack) versions. |  |

| Volition is a simple, inexpensive duplex connector that uses no ferrule at all. It aligns fibers in a V-groove like a splice. Plug and jack versions, but one can field terminate jacks only. |  |

| MU looks a miniature SC with a 1.25 mm ferrule. It's more popular in Japan. |  |

|

MPO

is a 12 fiber connector for ribbon cable.

It's main use is for preterminated cable

assemblies and prefab cabling systems. It has also been used in some

multimode transceivers for high speed

systems that use parallel optics - signals

transmitted over multiple fibers. The MPO is often referred to by a trade name, MTP.

|

MPO connector with 12 STs on a breakout cable  MPO connectors are aligned by pins and holes |

| Plastic fiber also requires

connectors and many versions have been used over the years. These two

are still popular. The Toslink connector is widely used for consumer

electronics and the AVAGO connector in equipment for general

applications. |

|

Here is an even more comprehensive guide to fiber optic connectors, including obsolete ones.

The ST/SC/FC/FDDI/ESCON connectors have the same ferrule size - 2.5 mm or about 0.1 inch diameter- so they can be mixed and matched to each other using hybrid mating adapters. This makes it convenient to test, since you can have a set of multimode reference test cables with ST connectors and adapt to all these connectors. Likewise, the LC and MU use the same ferrule (1.25 mm diameter) so mating is possible.

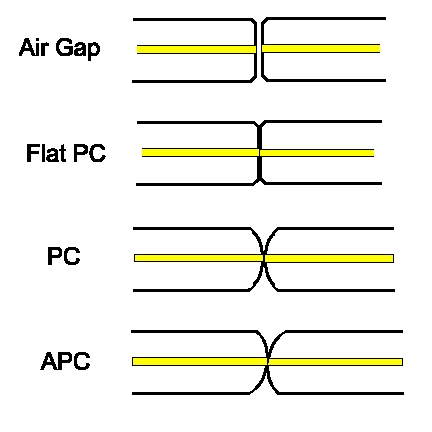

| Fiber

type |

Connector

Body |

Strain

Relief/ Mating Adapter |

| 62.5/125 |

Beige |

Beige |

| 50/125 |

Black |

Black |

| 50/125

laser optimized |

Aqua |

Aqua |

| Singlemode |

Blue |

Blue |

| Singlemode

APC |

Green |

Green |

Multimode

Terminations: Several different types of

terminations are available for multimode fibers. Each

version has its advantages and disadvantages, so

learning more about how each works helps decide which

one to use.

Singlemode

Terminations: Singlemode fiber requires

different connectors and polishing techniques that are

best done in a factory environment. Consequently most

SM fiber is field terminated by splicing on a

factory-terminated pigtail or using prepolished/splice

connectors or SOCs (splice-on connectors.) Singlemode

termination requires special connectors with much

tighter tolerances on the ferrule, especially the hole

for the fiber. Polishing requires special diamond

polishing film on a soft rubber pad and a polishing

slurry to get low reflectance. But you can put

adhesive/polish SM connectors on in the field if you

know what you are doing. Expect higher loss and

high reflectance.

Adhesive Terminations: All factory-installed connectors and many field-installed connectors use epoxies or other adhesives to hold the fiber in the connector ferrule and polish the end of the fiber to a smooth finish. Follow termination procedures carefully, as they have been developed to produce the lowest loss and most reliable terminations. Use only the specified adhesives, as the fiber to ferrule bond is critical for low loss and long term reliability! We've seen people use hardware store epoxies, Crazy Glue, you name it! And they regretted doing it. Only adhesives approved by manufacturers or other distributors of connectors should be used. If the adhesive fails, not unusual when connector ferrules were made of metal, the fiber will "piston" - sticking out or pulling back into the ferrule - causing high loss and potential damage to a mated connector.

The polishing process usually involves three steps which takes about a minute: "air polishing" to grind down the protruding fiber, polishing on a soft pad with the fiber held perpendicular to the polishing surface with a polishing puck and a quick final fine polish.

Epoxy/Polish: Most connectors, including virtually all factory made terminations, are the simple "epoxy/polish" type where the fiber is glued into the connector with epoxy and the end polished with special polishing film. These provide the most reliable connection, lowest losses (less than 0.5 dB) and lowest costs, especially if you are doing a lot of connectors. The small bead of hardened epoxy that surrounds the fiber on the end of the ferrule even makes the cleaving and polishing processes much easier - practically foolproof. The epoxy can be allowed to set overnight or cured in an inexpensive oven. A "heat gun" should never be used to try to cure the epoxy faster as the uneven heat may not cure all the epoxy or may overheat some of it which will prevent it ever curing. Don't use "Hot Melt" ovens either, as they use a much higher temperature and will ruin the epoxy.

"Hot Melt"

Adhesive/Polish: This is a 3M trade name for a

connector that already has the epoxy (actually a heat

set glue) inside the connector. You insert the

connector in a special oven. In a few minutes, the

glue is melted, so you remove the connector, insert

the stripped fiber, let it cool and it is ready to

polish. Fast and easy, low loss, but not as cheap as

the epoxy type, it has become the favorite of lots of

contractors who install relatively small quantities of

connectors. Remember you need a special Hot Melt oven,

as it needs a much higher temperature than is used for

curing epoxy.

Anaerobic Adhesive/Polish: These connectors use a quick setting "anaerobic" adhesive to replace the epoxy or Hot Melt adhesive that cures faster than other types of adhesives. They work well if your technique is good, but some do not have the wide temperature range of epoxies. A lot of installers are using Loctite 648, with or without the accelerator solution (Loctite 7471 or 7649), that is neat and easy to use.

There have

been several methods using UV-cured adhesives but they

have not become popular.

More

on processes used for adhesive/polish connectors.

Video on adhesive/polish termination can be

found on the FOA Channel on

Crimp/Polish: Rather than glue the fiber in the connector, these connectors use a crimp on the fiber to hold it in. Early types offered "iffy" performance, but today they are pretty good, if you practice a lot. Expect to trade higher losses for the faster termination speed. And they are more costly than epoxy polish types. A good choice if you only install small quantities and your customer will accept them.

Prepolished/Splice

And

Splice-On Connectors

Prepolished/Splice

Connector (Corning Unicam) and Splice-On Connectors (EasySplicer)

Prepolished/splice

and

splice-on connectors eliminate the need for field

adhesives and polishing by terminating connectors to a

stub fiber in a factory and attaching it to the fiber

with a mechanical splice (prepolished/splice

connectors) or a fusion splice (splice-on connectors,

called SOCs). Terminating the fiber them becomes a

splicing process instead of the more complicated

polishing methods. The termination process involves

cleaving the fiber and attaching the connector with a

built-in mechanical splice or using a fusion splicing

machine. It is faster than the adhesive/polish

connectors when done by an experienced tech.

These

connectors

require analysis of the economics of their use. Both

methods require investment in special equipment.

Prepolished/splice connectors generally require

special termination kits for each manufacturer's

connector due to the uniqueness of the connector and

splice. Some kits provide an inexpensive cleaver which

is difficult to use so it should be replaced with a

precision cleaver as used with fusion splicers.

Splice-on connectors require a fusion splicing

machine, more expensive than the kits for prepolished

splice connectors, and some of these connectors only

work with specific manufacturer's splicing machines.

The connectors themselves are more expensive than a typical connector used for adhesive/polish termination. The ones with mechanical splices are generally much more expensive than the fusion splice-on connectors. Another factor in cost is the yield. Fusion splice-on connectors will have lower loss and virtually 100% yield while mechanical prepolished/splice connectors will have average higher losses and lower yield.

Another

misconception concerns connectors that are installed

by splicing on the end of a fiber, wither by

mechanical or fusion splicing, or by splicing on a

pigtail. The connection loss of this type of

termination includes the typical connection loss

tested when mated to a reference connector plus the

splice used to attach the connector to the fiber, as

the splice is the attachment method and therefore

included in the connection loss. This is how standards

often list high losses for connectors because they

must include not only the direct attach

adhesive/polish connectors but also splice-on

connectors and array connectors with many fibers.

More

on prepolished/splice connectors.

Read more about termination processes and view the actual processes involved in termination with "Virtual Hands-On" tutorials. See the FOA Guide Table of Contents for listings of termination types under Components.

Hints

For Field Terminations

Here are a few things to remember when you are

terminating connectors in the field. Following these

guidelines will save you time, money and frustration.

Choose the connector carefully and clear it with the customer if it is anything other than an epoxy/polish type. Some customers have strong opinions on the types or brands of connectors used in their job. Find out first, not later!

Never, never, NEVER take a new connector in the field until you have installed enough of them in the office that you can put them on in your sleep. The field is no place to experiment or learn! It'll cost you big time!

Have the right tools for the job. Make sure you have the proper tools and they are in good shape before you head out for the job. This includes all the termination tools, cable tools and test equipment. Do you know your test cables are good? Without that, you will test good terminations as bad every time. More and more installers are owning their own tools like auto mechanics, saying that is the only way to make sure the tools are properly cared for.

Dust and dirt are your enemies. It's very hard to terminate or splice in a dusty place. Try to work in the cleanest possible location. Use lint-free wipes (not cotton swaps or rags made from old T-shirts!) to clean every connector before connecting or testing it. Don't work under heating vents, as they are blowing dirt down on you continuously.

Don't overpolish. Contrary to common sense, too much polishing is just as bad as too little. The ceramic ferrule in most of today's connector is much harder than the glass fiber. Polish too much will cause undercutting of the fiber and you create a concave fiber surface not convex as it should be, increasing the loss. A few swipes is all it takes.

Change polishing film regularly. Polishing builds up residue and dirt on the film that can cause problems after too many connectors and cause poor end finish. Check the manufacturers' specs.

Put covers on connectors and patch panels when not in use. Keep them covered to keep them clean.

Inspect and test, then document. It is very hard to troubleshoot cables when you don't know how long they are, where they go or how they tested originally! So keep good records, smart users require it and expect to pay extra for good records.

Not necessarily. Many manufacturers offer prefabricated fiber optic cabling systems for both premises and outside plant systems. In fact, the largest application for prefabricated systems is fiber to the home (FTTH) where it saves a tremendous amount of time in installation and cost. Using prefab systems requires knowing precisely where the cable will be run so cable lengths can be specified. Using CAD systems and design drawings, a complete fiber optic cabling system is designed to the customer's specifications and built in a factory using standard components. Early prefabricated systems (some are still available) simply terminated cables with standard connectors like STs or SCs and put them inside a plastic pulling boot with a pulling loop attached to the fiber strength members. The cable would be placed with the boot in place then removed to connect into patch panels.

Today, it's more common to use backbone cables terminated in small multifiber MTP connectors that are pulled from room to room and connected to rack-mounted modules that have MTP connectors on the back and single fiber connectors on the front (see photo of Fiberware system.) Like everything else, there are tradeoffs. The factory-assembled connectors usually have lower loss than field terminations but the MTP connectors, even factory assembled, are not low loss, so the total loss may be more than field terminated systems. Costs also involve tradeoffs, as factory systems are more expensive for the components but installation time is much less.

In new

facilities, considering prefabricated systems is

always a good idea, but all factors should be

considered before making a decision.

More on connectors and termination, including hands-on tutorials.

Videos

on fiber optic termination on the FOA Channel on

The

Importance of Cleaning Connectors

It

is very important to inspect and clean all fiber optic

connectors properly before testing, including the

connectors on all reference test cables. The core of

an optical fiber is quite small; so small that

airborne dust is often as large as the core of

singlemode fiber and even large compared to multimode

fiber. A small dust particle on a connector ferrule

can cause significant loss and reflectance when two

connectors are mated or contaminate fiber optic

transceivers. Dirt can sometimes even damage the

fibers. Liquids like oils on your fingers can

contaminate connectors and make cleaning difficult.

Cleaning

connectors has historically been done with pure

isopropyl alcohol (99% pure) and lint-free wipes in a

wet/dry method. Wet a wipe in a spot with alcohol and

wipe the connector ferrule end across the wet spot

then dry it on the dry wipe. However, today there are

many fiber optic cleaning products available that work

better and are easier to use. There are dry cleaning

methods as well as wet/dry methods, cleaning fluids

that are more effective than alcohol and more

effective wipes.

Every

test tech should have a fiber optic cleaning kit and

use it to clean all connectors using a

inspect/clean/inspect process to insure the connectors

are properly cleaned.

Splicing is

more common in outside plant (OSP) applications than

premises cabling, where most cables are pulled in one

piece and directly terminated. Splicing is only needed

if the cable runs are too long for one straight pull

or you need to mix a number of different types of

cables (like bringing a 48 fiber cable in and splicing

it to six 8 fiber cables.) And of course, we often use

splices for OSP restoration, after the number one

problem of outside plant cables, a dig-up and cut of a

buried cable, usually referred to as "backhoe fade"

for obvious reasons!

Splices: fusion on the far left, other types of

mechanical splices.

Splices are "permanent" connections between two fibers. There are two types of splices, fusion and mechanical, and the choice is usually based on cost or location. Most splicing is on long haul outside plant SM cables, not multimode LANs, so if you do outside plant SM jobs, you will want to learn how to fusion splice. If you do mostly premises cabling like MM LANs, you may never see a splice.

Fusion splicing is most widely used as it provides for the lowest loss and least reflectance, as well as providing the strongest and most reliable joint. Virtually all singlemode splices are fusion. Mechanical splicing is used for temporary restoration and for most multimode splicing. Read more on splicing below.

Tech splicing in a clean, controlled environment splicing trailer

Fusion Splices are made by "welding" the two fibers together usually by an electric arc. To be safe, you should not do that in an enclosed space like a manhole or an explosive atmosphere, and the equipment is too bulky for most aerial applications, so fusion splicing is usually done above ground in a truck or trailer set up for the purpose. (photo above) Today's singlemode fusion splicers are automated and you have a hard time making a bad splice as long as you cleave the fiber properly. The biggest application is singlemode fibers in outside plant installations. Fusion splices are so good today that splice points may not be detectable in OTDR traces. Some splicing machines can do one fiber at a time but Mass Fusion Splicers can do all 12 fibers in a ribbon at once. Fusion splicers cost $15,000 to $40,000, but the splices only cost a few dollars each.

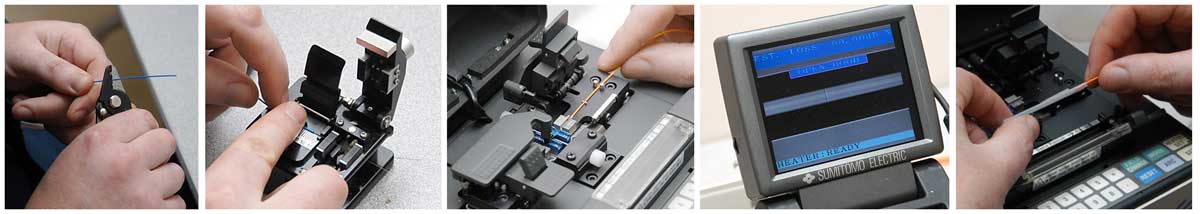

The Fusion

Splicing Process

Preparing the Fibers

The fusion splicing process is basically the same for

all automatic splicing machines. The first step is to

strip, clean & cleave the fibers to be spliced.

Strip the primary buffer coating to expose the proper

length of bare fiber. Clean the fiber with appropriate

wipes. Cleave the fiber using the directions

appropriate to the cleaver being used. Place each

fiber into the guides in the fusion splicing machine

and clamp it in place.

Running the splicer program

First choose the proper program for the fiber types

being spliced. The splicer will show the fibers being

spliced on a video screen. Fiber ends will be

inspected for proper cleaves and bad ones will be

rejected. That fiber must be cleaved again. The fibers

will be moved into position, prefused to remove any

dirt on the fiber ends and preheat the fibers for

splicing. The fibers will be aligned using the core

alignment method used on that splicer. Then the fibers

will be fused by an automatic arc cycle that heats

them in an electric arc and feeds the fibers together

at a controlled rate.

When fusion is completed, the splicing machine will

inspect the splice and estimate the optical loss of

the splice. It will tell the operator if a splice

needs to be remade. The operator removes the fibers

from the guides and attach a permanent splice

protector by heat-shrinking or clamping clam shell

protectors.

Mass (Ribbon) Fusion Splicing

Ribbon cables are fusion spliced one ribbon at a time,

rather than one fiber at a time. Thus each ribbon is

stripped, cleaved and spliced as a unit. Special tools

are needed to strip the fiber ribbon, usually heating

it first, then cleave all fibers at once. Many tools

place the ribbon in a carrier that supports and aligns

it through stripping, cleaving and splicing. Consult

both cable and splicer manufacturers to ensure you

have the proper directions.

Video

on fusion splicing can be found on the FOA Channel

on

Mechanical Splices

Mechanical

Splices are alignment components that hold the ends of

two fibers together with some index matching gel or

glue between them. There are a number of types of

mechanical splices, like little glass tubes or

V-shaped metal clamps. The tools to make mechanical

splices are cheap, but the splices themselves are more

expensive. Many mechanical splices are used for

restoration, but they can work well with both

singlemode and multimode fiber, with practice - and

using a quality cleaver such as those used for fusion

splicing.

More

on mechanical splicing.

Which

Splice ?

If cost is the issue, we've given you the clues to

make a choice: fusion requires expensive equipment and

but makes cheap splices, while mechanical splices

require inexpensive equipment and expensive splice

hardware. So if you make a lot of splices (like

thousands in an big telco or CATV network) use fusion

splices. If you need just a few, use mechanical

splices.

Fusion splices give very low back reflections and are

preferred for singlemode high speed digital or CATV

networks. However, they may not work well some

multimode fibers, so mechanical splices may be

preferred for MM, unless it is an underwater or aerial

application, where the greater reliability of the

fusion splice is preferred.

Making

Good Splices

Making consistently low loss splices depends on proper

techniques and keeping equipment in good shape.

Cleanliness is a big issue, of course. Fiber strippers

should be kept clean and in good condition and be

replaced when nicked or worn. Cleavers are most

important, as the secret to good splices - either

fusion or mechanical - is having good cleaves on both

fibers. Keep cleavers clean and have the scribing

blades aligned and replaced regularly. Fusion splicers

should be properly maintained and fusing parameters

set for the fibers being spliced. For mechanical

splices, light pressure on the fiber to keep the ends

together while crimping is important. Use a visual

fault locator (VFL)

to optimize the splice before crimping if

possible.

More on splices, including hands-on tutorials

|

|