Testing Optical LANs (OLANs)

Introduction

Centralized Cabling - Fiber to the Desk and Fiber To The Office

Passive Optical LANs

Designing And Installing Optical LANs (OLANs)

Testing OLANs

Introduction

Testing optical LANs is different from testing other premises cabling networks which use fiber optics. FTTO and passive OLANs use singlemode fiber while centralized fiber (FTTD) is generally implemented in multimode fiber. Passive OLANs use a single fiber in both directions at different wavelengths and have splitters in the network. Splitters add substantial loss to the links and can cause confusion when tested with OTDRs. There may even be multiple splitters if they are cascaded which must be considered when creating a loss budget to compare against test results.

As with all fiber optic links, troubleshooting requires knowing the architecture of the system, expected link losses (loss budget) and optical signal levels and typical problems that may be encountered. As always, we emphasize the importance of having documentation on the system before testing and troubleshooting.

Caution: FTTO and passive OLANs use singlemode fiber and primarily use APC (angled physical contact) connectors to prevent problems with reflectance at connections. APC connector are color-coded with green bodies and/or strain-relief boots. Reference cables for insertion loss or OTDR testing must have matching APC connections for testing to prevent damage to the connectors and get realistic test results.

SC Connectors: Multimode (beige), Singlemode PC (blue), singlemode APC (green) - DO NOT MIX THEM UP!

Warning: Since most OLANs are based on singlemode fiber, the quality of the patchcords is EXTREMELY important. Contractors installing OLANs have complained about the quality of singlemode patchcords bought from unknown suppliers and/or based on price. One contractor had to replace over half of the patchcords because they did not work. Buy patchcords from known suppliers, preferably those qualified to telco purchasing specifications to avoid problems. It is recommended to test a sample of patchcords from each batch just in case.

Visual Inspection And Cleaning

Since FTTO and passive OLANs use singlemode fiber, cleanliness is a major problem. Whether you are dealing with prefab cable assemblies, prepolished/splice connectors or patchcords, every connection should be cleaned and inspected before being tested or connected. For more information on these processes see these FOA Guide pages:

Cleaning Fiber Optic Connectors

Microscope Inspection of Connectors

Link Insertion Loss Testing

The link is a single run of fiber, e.g.: from OLT to ONT at each user work area. The fiber run may have connectors, the number of which depending on whether the links are spliced or use connectors for terminations. Links may use preterminated cables to speed installation. All links should be tested for insertion loss.

You must measure insertion loss, a test which is similar to how the transmission equipment will use the fiber.

Since we consider 3 types of OLANs, there are three testing options.

1) FTTD (centralized fiber) uses multimode fiber with transmission at 850nm. Test with a source at 850nm and reference cables which match the cable plant (some still use 62.5/125 (OM1) fiber but 50/125 (OM2/3/4) fiber is more common.) The use of mode conditioning is recommended. Testing in one direction is generally considered adequate, but if the test requirements call for bi-directional testing, it must be done. Compare results to the loss budget for the link.

2) FTTO links are singlemode fiber and most transmission is at 1310nm, so test with a 1310nm laser source intended for singlemode testing. Testing in one direction is generally considered adequate, but if the test requirements call for bi-directional testing, it must be done. Compare results to the loss budget for the link.

3) In passive optical LANs, the loss of the PON splitter must be included in the loss budget for the link. See FTTH Architectures for more information on PON splitter losses.

After the link is installed, it needs testing from end to end. The end-to-end loss includes the connectors on each end, the loss of the fiber in each link, the connectors or splices on the splitter and the loss of the splitter itself. Since the fibers are being used bi-directionally and connector or splice loss may be different in each direction if the fiber core diameter (mode field diameter for SM fiber) is different, testing in both directions is important too.

You must measure insertion loss from the OLT to the ONT with OLTS at all wavelengths and bidirectionally to check all operational modes - similar to how the transmission equipment will use the fiber. Optionally, the installer may test splitters separately. If these are pretested, as they should have been, this may not be necessary or advisable, especially since it is time-consuming and costly.

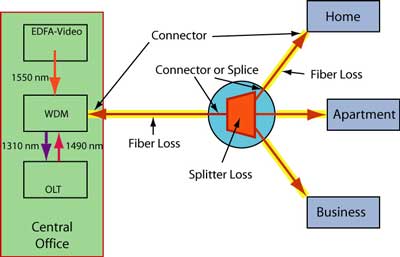

This diagram shows the OLT which uses 1490nm downstream and 1310nm upstream. It also shows AM video at 1550 downstream, not common but sometimes used on passive optical LANs. Special FTTx PON OLTS are available that test the proper wavelengths in each direction, simplifying testing logistics. However, since most SM test sets have sources at 1550 and 1310nm, one may test at 1550nm instead of 1490nm downstream because the difference in loss of the cable plant will be small.

OTDR Testing

OTDR testing on a OLAN can be tricky because of the limitation in distance resolution of the OTDR. Some OTDRs, mostly those designed for LANs or FTTH MDUs, have very short distance resolution, but even those will have difficulty with some components like connectorized splitter modules and breakout modules used in some prefab cable systems. However, if you have a high-resolution OTDR, it can be used to check for high reflectance connections. The usual excuse for using an OTDR, finding stress points in the cables caused by installation, is no longer possible when one uses bend-insensitive fiber. If the OLAN covers a campus or metropolitan area, using an OTDR will allow testing the longer OSP (outside plant) installations. Finally, OTDR traces upstream and downstream through a splitter are different and are often confusing.�

If you plan to use an OTDR to test OLANs, read this on testing PON FTTH systems.

Other OLAN Testing Issues

Network equipment will be tested as the system is turned on or for troubleshooting. Will the network equipment transmit and receive properly? If the cable plant is installed correctly and tests within specifications for loss and reflectance, it should. Most OLAN equipment has extensive self-testing capability and that may prove sufficient for most testing. PON couplers may have a second port on the upstream side just for testing or unused downstream connectors may be useful for testing, especially with OTDRs.

The network equipment should be tested for optical power. The transmitter output should be within specifications, as should the receiver input, when tested with a calibrated optical power meter set at the proper wavelength(s). If testing is done while all three systems are operating at their respective wavelengths, a power meter with wavelength selective input is required. Power at the receiver is critical. Too low and the signal-to-noise ratio will be too low; too high and the receiver will saturate. Both conditions will cause transmission errors. High power is not uncommon, so attenuators may be used in these links to reduce power to acceptable levels.

Data transfer testing with a protocol analyzer is the final test. It will be done using specific protocol testers for the data formats being transmitted. Personnel doing these tests are probably not the same that test the cable plant as each have specific training and test equipment needs.

Remember that ONTs are generally capable of loopback testing under remote control. This may mean more sophisticated testing is unnecessary for troubleshooting.

OLAN Safety Issues

OLAN safety issues include all the usual fiber installation issues, for example working with bare fibers, solvents and adhesives. But OLAN networks, especially passive OLANs, have several other potential problems.

Links carrying AM TV signals will have high power from EDFAs, especially before the splitters. And links may have multiple equipment transmitting simultaneously. Either case can cause high optical power that can be dangerous to worker’s eyes. Care should be taken to not expose eyes to light from the fibers and to always use microscopes with infrared filters, just in case. Since systems may have multiple systems transmitting on the same fiber, it is harder to ensure that all systems are turned off for inspection or testing, also. And, since up to 32 users may be sharing the CO based network equipment, turning off systems for troubleshooting is not desirable, so testing may have to be done with equipment in service. Exercise care. More on fiber optic safety.

More On OLANs

Introduction

Centralized Cabling - Fiber to the Desk and Fiber To The Office

Passive Optical LANs

Designing And Installing Optical LANs (OLANs)

Testing OLANs

Training And Certification

FOA has an Optical LAN (OLAN) specialist certification (CFOS/L) with training available from FOA approved schools. Read more.

Here are more sources of information on Optical LANs.

The FOA YouTube Lecture 30, OLANs, Optical LANs

There is a new trade association focusing on passive optical LANs: APOLAN

Tellabs

Motorola/ARRIS

Cliff Walker's FTTO paper

3M on POLs

TE Connectivity on Optical LAN Solutions

Corning Cable Systems on Optical LAN Solutions

Table of Contents: The FOA Reference Guide To Fiber Optics

|