Cleaning

Fiber Optic Connections

For

a comprehensive guide to connector inspection and

cleaning, go here.

With fiber optics, the tolerance to dirt or contamination

on the ends of the ferrules of a connector is near zero.

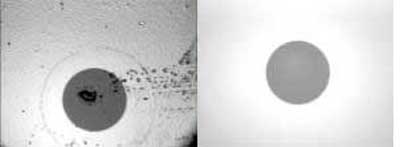

From left: dirt, contamination, clean connector

Airborne dirt particles are about the size of the core of

SM fiber and are usually silica based - they may scratch

PC connectors if not removed! Patch panels have mating

adapters that can become contaminated if left open to the

air or scrape off foreign particles under repeated usage.

Test equipment has fiber-bulkhead outputs that need

periodic cleaning, since they may have hundreds of

insertions of test cables in short time frames.

We recommend you always keep dust caps on connectors,

bulkhead splices, patch panels or anything else that is

going to have a connection made with it. Not only will it

prevent additional dust buildup, but it will prevent

contamination from being touched or damaged from dropping.

Always clean connectors before mating, whether for testing

or making network connections.

When testing, we recommend that connectors on both the

reference and tested cables be cleaned before every test,

as every time the connector is exposed to air, it can

accumulate dust. Typical airborne dust is almost the size

of the SM fiber core, so cleaning every time is even more

important than MM. A secondary effect is that if the

connectors are dirty, it can scratch the end finish (most

dirt is silica (sand) based) and cause higher reflectance

if not loss.

Cleaning Connectors

There are several types of cleaners which can be used.

Many companies sell cleaning kits for fiber optics,

including Sticklers, Chemtronics., NetOptics, AFL etc.

(Links below) They are readily available from

distributors. Some are dry, some us cleaning solutions.

They are all good solutions if you follow their directions

carefully and always inspect after cleaning.

You

may use lint-free pads and isopropyl alcohol to wet-clean

the connectors. Some solvents MIGHT attack epoxy, so only

reagent-grade 99% isopropyl alcohol should be used. Never

use cotton swabs or cloth it will leave threads behind.

Clean and dry the end of the ferrule just before

insertion. If you wet-clean, use a dry lint-free pad to

dry the connector off and then inspect it to ensure it is

clean. You

may use lint-free pads and isopropyl alcohol to wet-clean

the connectors. Some solvents MIGHT attack epoxy, so only

reagent-grade 99% isopropyl alcohol should be used. Never

use cotton swabs or cloth it will leave threads behind.

Clean and dry the end of the ferrule just before

insertion. If you wet-clean, use a dry lint-free pad to

dry the connector off and then inspect it to ensure it is

clean.

Some optical cleaners for lenses may leave residues.

Residues usually attract dirt and make it stick.

We have used Alco Pads which are pure isopropyl alcohol on

lint-free pads for over 20 years with no problems. After

the alcohol evaporates, they are good to dry the ends of

the ferrules after cleaning.

All "canned air" has a liquid propellant and may leave a

residue unless you 1. hold them perfectly level when

spraying and 2. spray for 3-5 seconds before using to

insure that any liquid propellant is expelled from the

nozzle. These cans can be used to blow dust out of

bulkheads with a connector in the other side or an active

device mount (xmit/rcvr). NEVER use compressed air from a

hose (they emit a fine spray of oil from the compressor!)

or blow on them (you breath is full of moisture , not to

mention all those germs!)

A better way to clean these bulkheads is to remove both

connectors and clean with Alco Pads, then use a swab made

of the same material with alcohol on it to clean out the

bulkhead.

Detectors on FO power meters should also be cleaned

occasionally to remove dirt. Take the connector adapter

off and wipe the surface, then air dry or dry with a

lint-free wipe.

Ferrules on the connectors/cables used for testing will

get dirty on the sides as well as the ends by scraping off

the material of the alignment sleeve in the splice

bushing. Some of these sleeves are molded glass-filled

thermoplastic and sold for multimode applications. These

will give you a dirty connector ferrule in 10 insertions.

You can see the front edge of the connector ferrule

getting black. The alignment sleeve will build up an

internal ledge and cause a gap between the mating ferrules

- creating an attenuator!

Use the metal or ceramic alignment sleeve bulkheads only,

especially for testing where you have repeated insertions.

Cleaning contaminated connectors requires aggressive

scrubbing on the ferrule sides with the AlcoPad and

tossing the bulkhead away.

For

a comprehensive guide to connector inspection and

cleaning, go here

LInks

- Ed

Forrest is the guru of cleaning. He's written a number

of books on fiber cleaning - yes, it's a big enough

subject for more than one book - and these are THE

references on cleaning. His website is http://www.fiberopticprecisioncleaning.com/

and he has videos on YouTube.

( Use Code FVCFR80DX for a 20% discount on all

www.createspace.com book

orders.

-

- MicroCare

Sticklers

brand

ITW

Chemtronics

Cleantex

Alco Pads

|