FTTH Case Studies - Building A "Terabit City" And "Do-It-Yourself" FTTH

Building A "Terabit City

Why Stop At Gigabits? Design Fiber Networks For Terabits - It's The Future!

When discussing fiber infrastructure for cities, we mostly talk about

"Gigabit Cities," which are certainly the state of the art today. GPON

or 10GPON are the way to provide gigabit FTTH, and DOCSIS-3 or RFOG can

provide similar bandwidth for CATV systems. 5G and WiFi 6 wireless

promise almost as much bandwidth, although they are still unproven.

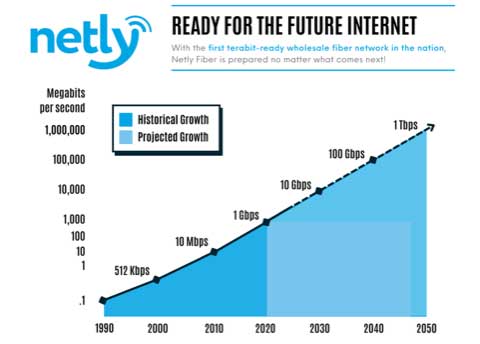

But fiber optic networks are good for 20-40 years at least, so what

happens as time moves on? Is Gigabit good enough? Based on past history

of the communications networks and the Internet, the answer is obvious,

of course not. So doesn't it make sense to design fiber optic networks

today that will be good in the future - the Terabit future?

Graph of Internet speeds from Netly Fiber.

Another issue that makes sense is "open access." If the owners of the

fiber optic cable plant are not service providers, they can provide the

connections to the users and allow multiple ISPs, CATV companies,

telcos, etc. to colocate in their head end. If a customer wants to add

or change service providers, only a simple patchcord change is needed.

Open access networks are preferable for cities because it can allow more

flexibility in offering services to citizens and for the city's own

uses.

Can networks like this be built today? That's what a company called

Netly Fiber has done in Solana Beach, CA. In June 2022, Netly completed

their 2-year project of building a fiber network in Solana Beach that

shows that with some forethought, you can build "Terabit" fiber optic

networks today that should be good for the lifetime of the fiber.

(An aside: When Jack Demers, an entrepreneur in

wireless, got interested in fiber over 5 years ago, he called FOA

asking questions. He came to our office and spent most of a day

discussing the work we had done with FTTH, starting with helping Verizon

with FiOS and our recent work in the DIY projects like Southern

Fiberworx and Connect Anza. We discussed a lot of topics that day and

since then we have continued our conversations as Netly has gotten

started and begun operations. And, for full disclosure, your editor, JH, was a minor shareholder in Netly.)

What exactly is Netly doing that is different? The multi-million dollar

project took two years to complete and includes ultra-high speed dark fiber access for every residence, business, traffic light, and institution in the city.

To achieve terabit speeds the Netly team took a bold approach and built

multiple dedicated strands of fiber to each address located on city

streets. Over 30,000 fibers are available for Solana Beach's 6,000

households.

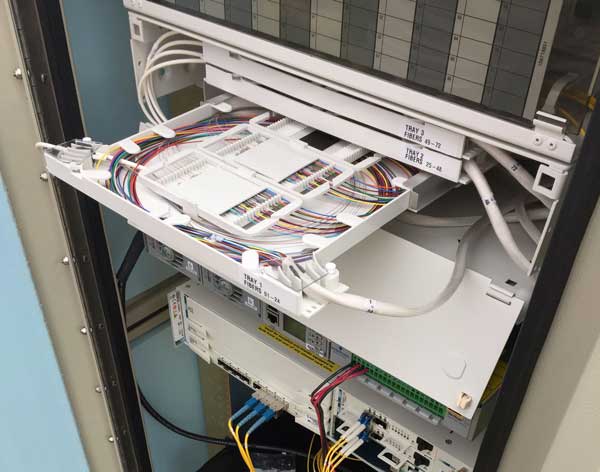

Yes, every user in the city can have dedicated fiber back to Netly's head end. And the fiber network is open access;

Netly is not an ISP, telecom or CATV company, they just provide the

dark fibers and colocation space for service providers. Service

providers locate their equipment at Netly's head end, patch into their

customers' fibers and provide their services using whatever protocols

they choose.

Service providers' equipment (including splitters for PON networks) are placed in the Netly Edge Fiber Center (headend)

Does a centralized fiber infrastructure make sense? Most networks today

are based on PONs, passive optical networks that use splitters to serve

multiple users from a single network GPON OLT port over one fiber, with

splitters placed along the network route. But will that architecture

still work in a decade or two? Possible, as 10G is already here and 100G

PONs using coherent transmission in R&D. And, then again, maybe

not. In the future we may need direct connection to every user.

The centralized fiber network Netly uses is really cheap insurance for

the future. If you are using GPON on Netly's cable plant today, you put

your OLT in their head end along with the PON splitters and connect to

every user on their dedicated fiber. If the architecture changes to

direct connection to the user in the future, a simple change of

equipment is all that is needed.

Is centralized fiber affordable today? Netly thinks so. But they are utilizing state-of-the-art products and technologies.

Based on his analysis of the market and new developments in technology,

Jack developed a unique business plan for Netly. The notion of

centralized fiber with a connection to every user makes sense today

because fiber is inexpensive and this architecture reduces the need for

numerous fiber distribution hubs and pedestals for splitters or other

equipment scattered around the service areas. And centralized fiber

architecture is ready for terabit applications.

For the cities on the Southern California coast Netly was interested in,

all were somewhat urban but mostly suburban in geography. Underground

installation would be required in areas where aerial cables were not

permitted, so using microtrenching made sense for the installation

method. Working with Corning, Netly chose a microcable that could be

blown into microducts. Each trench route has a microduct with six ducts

in a row. When only one duct was used, 288 fibers in the microcable were

available, but each route could be expanded to 6 of the 288 fiber

microcables for 1728 fibers total.

Netly microtrenches then installs 6 microducts.

Netly's microtrenching technique deserves a mention also. Where

possible, that is there are no conflicts with other buried utilities,

they trench at

the joint between the road pavement and the curb, minimizing damage to

either. Drops are done in small handholes near the curb, leaving an

installation that is almost undetectable. And installation is quick,

making for minimal disruption in a neighborhood.

Besides a unique model for the FTTH cable plant, Netly has used a

different model for their financing. Netly is funded by private

investors who believe this is the best model for FTTH networks and

offers the greatest potential for future growth.

Do It Yourself FTTH

Do

you think that creating a FTTH network is only

possible if you have the resources of a Verizon or

Google? That you need a contractor with lots of

experience in designing and installing the fiber

network? Or an IT department who can install and

operate the equipment? Well, think again...AND

IF YOU ARE INTERESTED IN DIY FTTH, DO NOT MISS THE

INFORMATION AT THE END OF THESE STORIES!

With

most people agreeing that broadband Internet is an

essential utility, the problem becomes how to get it to

places that incumbent service providers don't have any

interest in serving because of the cost? More and more

groups are deciding to do it themselves. DIY FTTH is

completely feasible and hundreds of organizations are

doing it already. These DIY FTTH projects are being done

by cities and towns, utility coops, especially electrical

coops who need fiber for their grid management anyway, as

well as private groups like homeowners' associations, real

estate developers and even private companies with venture

capital funding.

Perhaps the best known is the Electricity

Power Board of Chattanooga, TN, EPB has shown that

gigabit broadband can transform a sleepy city into a

booming manufacturing (VW factory) and tech city. But you

don't need to be as big as EPB to bring broadband to your

area as these two examples show.

Southern

Fiberworx, Cordelle, GA

About

2014, FOA was contacted by Greg Turton of Cordele, GA. who

was curious about what was involved in creating a FTTH

network. Greg is a real estate developer who also owns

several local hotels. Where he lives and builds homes is

way outside of a service area that anybody wants to build

good broadband, forget FTTH. Cordele itself has a

population of only about 15,000 and is one of those small

cities along the Interstate highway that are everywhere in

the US.

We answered Greg's questions and led him to some of the

FOA Guide web pages and YouTube videos about FTTH to get

him started. More conversations discussed how to get

connections as an ISP, types of components and suppliers,

etc. Fortunately the local electrical utility has lots of

fiber but they were restricted from building their own

FTTH network because Georgia was one of 19 states where

lobbyists for the incumbent providers got laws passed

restricting their ability to operate a FTTH system

themselves. But they were more than willing to lease dark

fiber to Greg at really good rates. And there were good

choices on getting an Internet connection. As he got more

serious about the project, we introduced him to two FOA

Master Instructors, Eric

Pearson and Dominick

Tambone, in Atlanta, just two hours away.

Greg hired Eric to come to Cordele and train him and

several more of his people. Eric taught them how to work

with cable, prepare the cable and splice it, dress cables

in splice closures, pedestals, manholes, etc. Eric,

Dominick and the FOA had many conversations with Greg

about his project and the potential suppliers to it. As

construction began, Dominick came down to Cordele to help

with the early installations.

Now that you know where we're going with this story, let's

talk about Greg. He is not your usual fiber optic project

manager. First he is a second generation developer,

following in his father's footsteps. He is accustomed to

getting into the depths of a project, understanding the

risks and making investments. He's also a "tinkerer" - he

likes projects and challenges. He's a private pilot who

has invented and manufactures two types of air

conditioners for small airplanes which he built in his

shop and tested in his own airplane. He makes electrical

hardware he invented for his own hotel to make using tech

devices more convenient for his guests. He also has a

great crew of people working for him and lots of local

connections.

To Greg, FTTH was another challenge, and after he became

educated himself, he knew he and his crew could build it

themselves.

And they did!

FOA visited Greg and his crew recently (they now are known

as "Southern

Fiberworx") and saw what they have done. It's

amazing - simply amazing - and should be an inspiration to

any other group wanting to build their own system. Here's

some photos and descriptions of their project.

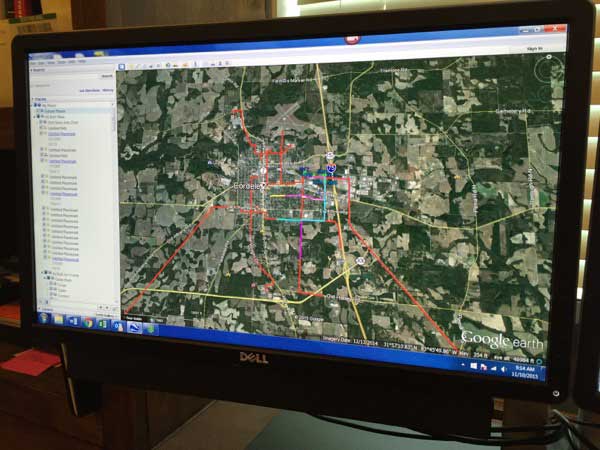

Meet

Greg Turton. Greg and his crew had a lot to learn and

accomplish before the project even started, as we

mentioned above. They also had to figure out how to

document the system as they designed and built it,

something they accomplished using Google Earth.

As

they started buying equipment for splicing and testing,

the needed a splice trailer. No problem, they built one.

Based

on their training, they knew they needed a splicing

trailer for work in the chageable South Georgia weather. A

small converted travel trailer provided the base for their

splicing trailer and they furnished the inside with a work

counter and racks and cabinets for storage. Air

conditioning was furnished by a local company that wants a

fiber connection themselves. The white rectangle on the

right is the entry for the fiber optic cables being

spliced - a converted home doggy-door!

Rather

than investing in heavy equipment, they rent from local

companies. They converted a large utility trailer to carry

cables and conduit.

Most

cables were installed by trenching. In an area that has

lots of underground utilities, they had to be very

careful. They started by calling utilities before they

started and manually digging holes before using the

backhoe. Finding after a few near-misses that wasn't

sufficient, they bought a top quality underground locator

and learned how to use that to double-check before

digging.

To

avoid digging up paved roads or driveways, they used

directional boring. It also worked well for several

bridges crossing small streams.

Splice

closures were put into hand holes or pedestals like

this one. The cable was laid along two lane roads

along with other utilities.

Here's

Greg with one of the equipment pedestals needed to get

connections into a remote area.

Neat

splice trays - they learned well from Eric Pearson's

training.

Here's

Greg and David Herlovich, his assistant, with the

equipment for their head end. They chose ADTRAN equipment

for their system because of their reputation, knowledge

and support, plus they are nearby in Huntsville, AL so

Greg can fly his plane over to visit the factory when

necessary.

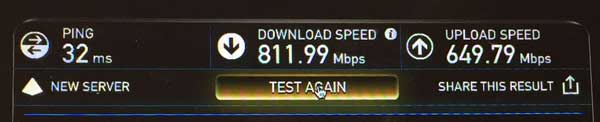

The

proof is in the performance, of course. This is a computer

at Greg's house connected to his network doing a

speedtest.

And

there you see the results of the speedtest on a "do it

yourself" gigabit FTTH network.

When

we visited Greg in November, 2015, Southern Fiberworx had

just started installation. They had already connected 30

homes and had over 100 scheduled for installation. His

original goal was to pass about 800 houses in his

development and sign up 30-40%. Southern

Fiberworx works like Google Fiber; get your

neighbors together and sign up and they build that

neighborhood next.

While we were in Cordele, we talked to some local

businesses and discovered that what Greg had been telling

us was true - the local enthusiasm for what he was doing

was amazing and people want to get connected ASAP. Because

Greg knows practically everybody in town and has talked to

many as he got permits and help building the system so

far, they know what he's doing and want him to expand

beyond his development to cover the entire town. As the

word spread, the county expressed similar interest in his

expanding the Southern Fiberworx footprint to cover the

county. Then the next county approached him with the same

idea.

While we were in Cordele, Greg asked us to visit his

bankers who wanted to know more about building a FTTH

network - you know, from the investment point of view. To

date, no kidding, Greg has funded Southern Fiberworx out

of his pocket! Yes, it does not cost that much to get

something like this started. But if he expands to the city

of Cordele and the two local counties, he may need to get

financial backers. We pointed out to the bankers that FTTH

provides high income with little overhead making good cash

flow. In addition, recently two CATV systems had been sold

for $5-6000 per subscriber - a whole lot more than it cost

to connect each of Southern Fiberworx subscribers on

gigabit FTTH. If that's not a good return on investment,

what is?

Southern Fiberworx is not the only independent FTTH

network FOA has been working with. We get calls often

asking how to get started and this is the best example we

have seen yet!

Connect

Anza

In

late 2014, Kevin Short, General Manager of the Anza

Electrical Cooperative called FOA to ask questions

about building a fiber optic network. FOA visited Kevin

and subsequently met with the Board of Directors of the

Coop to discuss ideas about building a fiber network over

their electrical network. Their electricity supplier was

pushing them to build fiber for grid management (Smart

Grid) and it seemed reasonable to assume that once the

backbone was built, expanding to provide Internet to their

customers was possible.

Kevin

Short, GM, Anza Electrical Cooperative

There was certainly a desire for better Internet because

they did not have any. It's easy to understand why. Anza

is really, really rural - located in the Southern

California high desert at the southern end of Mount San

Jacinto State Park.

Anza gets their electricity from an electric cooperative.

With the help of Franklin D. Roosevelt, who established

the Rural Electrification Administration in 1936, friends

and families banded together to create a new kind of

electric utility, where the voice of every person made a

difference. Electric cooperatives brought electric power

to the countryside when no one else would. Electric

cooperatives are owned by their members and focus on their

member needs and local priorities.

Anza Electric Cooperative, Inc. (AEC), energized in 1955,

is a member of Touchstone Energy® - the national brand of

electric cooperatives - providing power to the communities

of Anza, Garner Valley, Pinyon Pines and parts of Aguanga.

AEC provides power to 3900 homes, schools and businesses.

AEC's service area is nearly 700 square miles of high

desert with an elevation at roughly 4,000 feet where

winter weather can sometimes be a challenge. Anza is

located at an almost equal distance from Palm Desert,

Hemet and Temecula in Riverside County in Southern

California.

AEC's

fiber backbone run along their electrical lines.

While Anza is quite rural, it was only an hour's travel

from FOA HQ (then in Fallbrook, CA), so FOA President Jim

Hayes volunteered to do a series of half-day training

session for AEC personnel on fiber optics and installation

practices to familiarize them with what they would be

doing in the future to learn from the project so we could

share it with our readers.

AEC applied for and got a grant from the California Public

Utility Commission for $2.6 million, about $700 per

household, to help pay for the project. One thing is

important to understand about rural projects - they cost a

lot more than urban or suburban FTTH networks, and the

CPUC grant would cover only about half the total cost.

Since AEC is a coop, a bylaw change was voted on by Anza

Electric Cooperative members with an overwhelming 91.3% of

members approving the bylaw change to include fiber optic,

high speed internet service to our members along with our

traditional electric service.

Anza

- mostly ranches and mountains

We

dubbed the AEC project "FTTR" for "fiber to the ranch"

because of the typical customers in the service area!

To

do the design of the network, AEC used a unique solution.

They enlisted Jeffery Willis, a local resident who was a

student at the University of Colorado, Boulder's

Interdisciplinary Telecommunications Program, to do the

design as expansion of a pre-existing Master's Capstone

project that AEC assisted him with. This was a

brilliant idea due the success of this college feasibility

study. Before getting started, Jeff performed a plethora

of research and development on all aspects of the design,

including a survey of design software which he shared with

FOA for our readers. FOA (JH) helped him with some fiber

issues but he had relatively little trouble doing a very

good design for the project. "

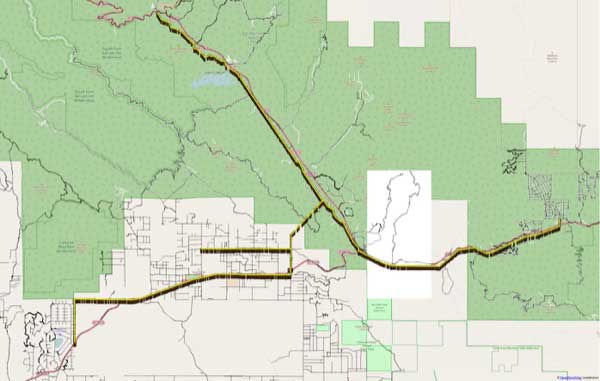

AEC's

fiber backbone plan

Much of the backbone ran along roads in the mountains that

connect the various population areas of the AEC service

area. Some areas had restrictions on where cables could be

run because the roads were designated "scenic routes."

One thing to consider in a project like this - you need

LOTS of cables! Anza had to store over a dozen spools of

cable - 20kft (about 4 miles or 6km) each, weighing

about 1600 pounds (726kg) each! Another thing they learned

was the length of the backbone was not the length of the

cable. They had to order 10-12% extra cable to accommodate

service loops, drops for splice closures, etc.

More

than 50 miles (80km) of cable stored in a AEC building.

They

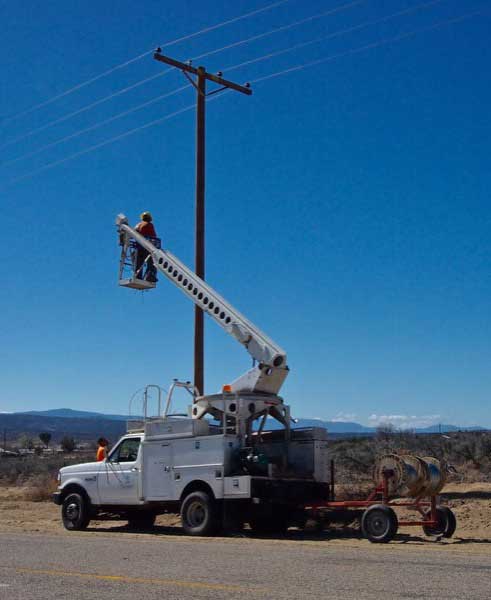

also needed more equipment, including this bucket truck

purchased used, cleaned up and made into a rolling

advertisement for "Connect

Anza."

The

bucket truck advertises Connect

Anza.

Installation of the cable plant for ConnectAnza was

somewhat out of the ordinary. The area covered by the coop

included some areas without telephone service and poles

and/or messenger wires needed to be installed in many

areas. One section had to be bridged with wireless because

the rod was a "scenic highway" and poles and aerial cable

were not allowed!

Installing messenger wires on the coops electrical poles.

Splicing was done on the ground, often in the desert.

This

closure has provision for a PON splitter and several drop

cables.

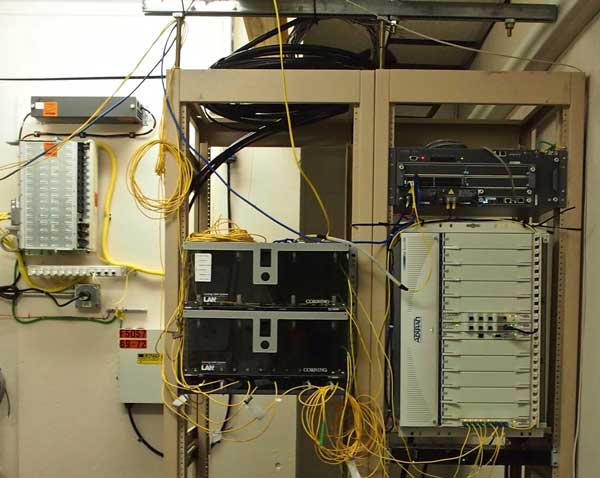

The head end for ConnectAnza is installed at their main

office in the town of Anza. This rack includes the router

for their Internet service and the ADTRAN OLT equipment.

In the bottom of the rack is the backup batteries, an

important part of the equipment for an ISP.

ConnectAnza

is now a fully functional ISP, one of the most rural

systems we know. They are proof that rural FTTH can be

built and it is certainly welcomed by their subscribers.

From no service, coop subscribers can get 100/100Mb/s

service for $49/month, 300/300 for $79/month. Low income

residents have a basic service of 20/20Mb/s for $20/month.

2021 Update

Since FOA began working with AEC in 2014, they have built out a large

part of the FTTH PON network, now connecting about 2,900 subscribers

including every business in their area. They also have gotten a RDOF

grant that will allow expansion of the network toward other small towns

nearby.

Besides the FTTH network, Anza has also made a significant commitment

to renewable energy, adding two solar farms of 3.5 megawatts and 1

megawatts. In additin, they have 2 megawatts of batteries online and 2.5

megawatts coming to allow providing 24/7 electricity from the solar

farms.

``

Satellite view of the 3.5 MW solar farm next to AEC offices under construction

AEC is a good example of how a small rural coop can successfully

provide state-of-the-art communications and power together in an area

that larger, for-profit companies would never consider possible.

LCS FiberCom

Three years ago, right after the beginning of the

pandemic lockdowns , FOA received an inquiry from Jamie Groskopf, asking

about getting a Do-It-Yourself (DIY) FTTH project started for a small town North of Houston, Texas.

After a half-dozen or so long and comprehensive emails, we heard no

more until December of 2022. I introduced him to Greg Turton of Southern

Fiberworx, one of the first to do a DIY FTTH project.

"I just wanted to reach out and give you a little update on the project I

started a couple years ago after reaching out to you for advice in the

Huntsville, Texas area north of Houston. We didn’t get construction

started until summer of 2021 and had 7 miles of cable to run to bring

fiber into the community. Inside the community we had another 78,000

feet of cable to install, mostly bored in and installed in conduit. We

have about 12,000 feet left to complete the main line installation past

every house and have made some progress in getting houses connected. We

just got our 100th subscriber connected and have another 200 signed up

and waiting in the community. "

"I took your advice and made friends with Grey Turton (Southern

FiberWorx) in Georgia. I made a couple trips out to spend time with him

and his team before making final decisions on which way to go."

Here's more about Jamie's project, LCS FiberCom, in his own words.

How did this project come about?

Waterwood is a large community in a rural area north of Houston, Texas.

The Property Owner’s Association approached several large providers to

build a modern alternative to the aging DSL system the local phone

company offers but the build costs didn’t meet their payback

requirements, even with incentives. There are over 28 miles of roads, a

golf course, and waterfront peninsulas with 2000 lots but only around

400 residences, which makes for a lot of additional build costs to cross

those undeveloped areas to reach the potential customers. The ground is

also particularly treacherous for this part of the state with very hard

sand/clay mixtures and random boulder sized rock formations. I proposed

a private project to build a modern fiber network that could remain

sustainable.

What background do you have?

I got my technical background started in the Air Force where I worked on

F-15 avionics systems. Later I got into security, automation, and

wireless systems as a hobby at first and then as a business. Fiber

optics intrigued me so I ordered a splicer and spent a lot of hours in

books and on YouTube learning what I could.

If you are building a DIY FTTH network, it helps to be a "Jack of

All Trades" because you may need to fix hydraulic hoses on your

equipment like Jamie can.

What type of system did you choose?

I looked at several topography methods and distribution systems. In the

end I chose the GPON system with a field split topography for price and

performance reasons. I looked at the 3 main GPON equipment providers but

when it was time to make the decision they all told me they could not

guarantee customer- end equipment (ONU/ONTs) and orders were as much as 6

months or more out with limits of 50 pieces. There were stories of

ISP’s not being able to add customers for lack of equipment. I wasn’t

sure if this was a legitimate shortage or a sales ploy to lock in early

orders but I couldn’t take that chance. I widened my search and finally

decided to contract manufacture my own GPON system from a large provider

overseas. I had to buy in bulk but they promised to have the entire

project worth of equipment manufactured and at my door in 30 days and

they came through as promised. I now have enough equipment to build

another community after this one as well as OLT spares. As an added

benefit this allowed me to tailor the specs to my needs and have the

items factory branded with LCS logos. I also offer VoIP telephone

services for those reluctant to abandon the telephone company and their

long-time home telephone numbers, which has been about 10% of our base

so far.

When suppliers couldn't provide products, LCS created their own.

Jamie had the electronics experience to do this but not every company

could. And it takes truckloads of equipment to build a FTTH network.

Have you been happy with the results?

I currently offer symmetrical 100Mbps and Gigabit plans. I’ve considered

offering a middle range plan as well as a 2-gig download option in

select areas but haven’t decided if I want to deal with the headache of

upgrading customers to multi-gig networking hardware yet. The network

handled the additional test demand well. We are too far out to have

redundant fiber ring options so we connect to our data center on a

single transport path. We had an outage on that path in May when the

main cable was severed in an adjacent city that took the provider half

the day to repair. Our local system has been working at a 100% rate.

What are your favorite and least favorite parts of construction?

I enjoy most of the construction. I have become quite a good horizontal

drill rig operator but I’m going to say using the large quad plow to

muscle in conduit at 4 feet deep several thousand feet per day is always

fun. My least favorite is probably just the Groundhog Day feeling of

chipping away at such a large amount of work day after day. I’ve worked 7

days a week for 18 months, averaging about one day away per month. At

some point I will be able to reduce my workload to something healthier

and more sustainable. It’s funny though, the few days I have taken off I

almost feel guilty about, thinking “I could have reached that goal

point today”. This type project definitely becomes all-consuming, at

least for me it has.

Jamie, like his mentor Greg Turton, likes to do construction work himself.

Not everything goes right - a water main for a golf course was damaged while directional boring and repaired.

What skills do you rely on most for this project?

All of them! When you take on a project like this you become engineer,

technician, politician, foreman, import specialist, customer relations,

field mechanic, salesman, contract negotiator, legal expert, government

liaison, plumber, electrician and more. You have to plan for some steep

learning curves because most people may have two or three of those

skills honed well, but you need all of them and more to keep moving

forward and give you a chance at success. I am very thankful for the few

people who have stepped in to help me where they can.

What would you do differently in hindsight?

Tough question, I don’t like to second guess past decisions. Looking

back there are some minor things that could have been improved but

overall, I was extremely fortunate that the decisions I made worked out

so well. It could have easily gone south if some of the non-traditional

choices didn’t work out well. Lots of research and asking questions

helped. My fiber management skills have improved a lot with practice so

at some point I will probably go back into the early splice points and

pedestals to organize them better but they are all working fine as is so

that is low on my to-do list.

Are your customers satisfied?

That is my main focus and I think I’ve done pretty well with that. I

personally meet with each customer at installation time and try to

follow up shortly after installation. The biggest issue I’ve had is the

same across the entire industry, customer’s WiFi expectations. I try to

assess each customer’s needs for WiFi at their home and educate them on

how to meet their expectations on their budget. I provide a wifi router

with the service but some customers with larger homes expect a one-size

fits all solution that just isn’t realistic. I make it a point to

explain the differences between extenders and mesh systems and why

getting their full gigabit to a single device over wifi is a tall order

even with their large 8 channel 5400 Mbps WiFi-6 gaming routers. It

amazes me that larger providers do all this work to bring service into a

customer’s home and then let their reputations suffer because the

customers experience poor service with the last 50 feet of connection

over underperforming wifi.

Did the pandemic cause problems?

Of course! I could write an entire article on those issues. It caused

delays for parts to repair equipment, labor shortages, cost increases,

and electronics equipment availability concerns. Our upstream provider

delayed our primary connection for several months as their crews were

constantly in some form of isolation or emergency coverage for most of

2021

How much has it cost, are you turning a profit yet?

A lot. I started doing initial budgeting and set my numbers in late 2019

which were used when the project started. The pandemic followed by the

government throwing billions of dollars to large providers to upgrade

their networks caused prices to increase substantially, as much as

triple on some items, and sub-contractors to be in short supply with

their prices increasing by 50-100%, and more recently the Fed’s interest

rate hikes have made profitability that much harder to reach.

I initially decided to keep total costs manageable by doing the bulk of

construction in-house so fortunately there was a degree of insulation

from the chaos going on in the fiber world but all the major materials

needed for construction have increased substantially since my initial

budgeting. Despite those issues and Waterwood having low home density

with so many miles of undeveloped lots to pass and 6 miles to bring

initial service into the community, I managed to keep the total cost per

passing at manageable levels by doing the bulk of the work with only

myself and one or two guys.

Recently I have been able to bring on an operator for the boring rig

with one or two of his guys because his machine is out for major

repairs. This has allowed me to catch up with splicing and getting

customers connected. To date we have 102 customers connected after

installing 70,000 feet of conduit and 170,000 feet of fiber-optic

cabling. We have 15,000 feet of conduit and 30,000 feet of cable left to

install with 200 more customers waiting for service. I expect to have

most connected by summer.

What is next for LCS Fibercom?

I’m looking for other areas to expand into and potential municipal or

utility partners to work with in the future. I laid the groundwork for

the network to expand into non-contiguous areas so I’d like to find

another community that wants improved services and keep growing.

More about LCS FiberCom

Additional

Reading on Rural FTTH

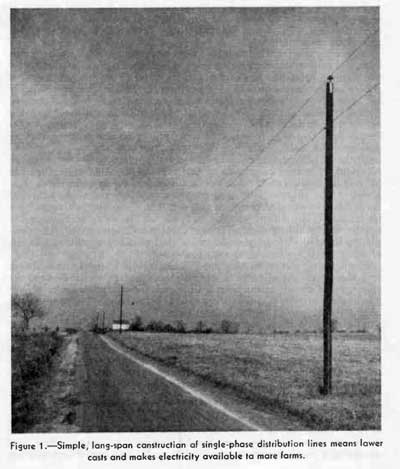

The

August

2021 issue of the FOA Newsletter compares rural

broadband today with rural electrification almost a

century ago. The situations are quite similar and the

solutions, including assisting rural electrical or telco

coops, are quite the same.

From the 1940 USDA yearbook article on rural

electrification.

If You Are

Considering DIY FTTH, Here Are Things To Remember

Legality: If

you are in one of 18 US States, your state legislators

have passed laws written by lobbyists for incumbent

service providers that prevent municipalities, other

governments or coops from becoming ISPs. Check the map

here. See

the map here. By the time you read this, all

this may have been negated by local or Federal laws.

Uniqueness: Like most fiber optic networks,

every FTTH installation is unique. It must be designed for

the location it is to serve and choices on components and

installation methods should be optimized for the system.

Construction and installation methods may include every

type of OSP installation. Suppliers familiar with FTTx can

advise customers on what others have done to make

installations simpler, easier and less expensive. Most

systems prefer to use as many factory-made components as

possible as they are generally less expensive than doing

the same work in the field. New installation methods

should be considered as well to reduce costs.

Consultants:

Be wary of consultants. Consultants can be

extremely valuable in designing a FTTH system, as long as

they have relevant experience, are up to date on new

components and techniques and are highly recommended by

previous clients. Unfortunately we have seen problems with

consultants, including over-designed networks with costs

much higher than necessary, installation practices

recommended that were unnecessary or ignore newer

technology, systems designed around components that were

higher performance (and price) than necessary, and in one

case a consultant took the clients payment, went away for

a year and came back with an admission that they could not

design the network (but they kept the consulting fees.)

Contractors: As with any fiber optic project, the

quality of the installation depends on the quality of the

installer. Look for contractors with knowledge, experience

and references. And preferably relevant certifications

like the FOA CFOT. Be especially wary of subcontractors.

Any subcontractors should have equal qualifications and be

approved by the network owner. We have seen landscape

contractors with no fiber training used as subcontractors

for cable plant installation - one cut several cables to

buildings that had been installed by a member of the FOA

advisory board!

Call Before You Dig! Every day some major fiber

optic cable is cut by a contractor.

The jurisdiction issuing permits should help you with

locating other buried utilities. There is

a service that helps you locate underground utilities that

may be in your construction path. See the FOA web page on

Digging

Safely.

What Fiber Do

You Already Have? Before you

design or install a new fiber optic cable plant, inventory

the fiber you have already and/or negotiate to lease fiber

where others have cables with dark (unused) fibers. Also

talk to other organizations who may need communications to

see if they want to share costs or lease dark fibers or

communications links from you. Cities, counties and states

need fiber. Utilities need fiber. Fire and life safety

organizations need fiber. Traffic departments need fiber.

Cellular companies really need a lot of fiber.

What Other

Services Can Share The Fiber? Consider what

other services than FTTH you can carry on your fiber optic

cable plant - cellular backhaul, traffic systems,

security/surveillance systems, leased fiber, etc. to

generate additional revenue. A few years ago a large

American city sent out a RFP (request for proposal) for an

urban FTTH network. The document dealt strictly with FTTH

to connect the city's citizens with fiber and ignored all

the other services the city had that already used or

needed fiber - city communications, security/video

surveillance, intelligent traffic management, public

transportation communications, wireless networks(small

cells and 5G), utility communications, etc., etc., etc.

Dig Smart -Dig

Once: This same document also covered

the difficulty of urban installation - digging up streets

already filled with underground utilities, limited space

for pedestals, few options for aerial cable and

other issues that are typical problems for urban fiber

installation. No mention of "Dig Once" to make future

installations easier. Share fibers. Use spare fibers. Use

additional wavelengths in current fiber. Consider all the

alternatives. Plan ahead - future proof is a myth, but one

can make certain decisions that will make the future

easier. If you are considering using

FTTH design software, ask to talk to customers who have

used it. Determine what you need to know first in order to

use it, e.g. GIS data on every utility pole, manhole or

handhole, subscriber location, etc. and how much training

it takes to become proficient. Will you use your personnel

or hire outsiders, and how do you evaluate them.

Cost Savings:

Fiber optic cable and components are not

expensive, but labor is. Saving money on components may

look good in first analysis, but more savings will come

from optimized designs and efficient installation

practices. More experienced contractors are more efficient

and may save costs by their speed and efficiency.

And design for the future - if you dig a trench for

anything, not just fiber but any underground utility, bury

a number of fiber ducts for future use, install cables

with more fibers than you need - lots more - fiber is

cheap, installation is expensive. The program is called

"Dig Once."

Take Rates Are

Important: "Take rates" for new FTTH networks

vary from low to high, depending on the satisfaction with

the current ISP (Internet service provider.) When Google

Fiber started in Kansas City, the take rate was high

because the current service was bad, but in later cities

when the local ISPs knew they were coming and improved

their service and/or lowered their prices, the take rate

was lower. Competition tends to drive take rates and take

rates determine the economics of the system, Know your

competition. Offering gigabit services are often the top

selling point of FTTH. Every GPON network is a gigabit

network, but subscribers can opt for slower speeds at

lower costs.

What Makes

A Successful Fiber Optic Project?

People call FOA for advice all the time. Most of the calls

deal with technical questions about products, installation

and testing. But in one call; a manager who was starting

to plan a fiber optic project wanted advice on how to

proceed. It was a long call! His basic question was “What

does it take to have a successful fiber optic project?” We

responded with 4 words: financing, commitment, expertise

and patience. (This section is repeated from the

introductory section on FTTH because it's important for

the designer and managers of a FTTH project.)

Financing: The story goes that

someone asked Neil Armstrong what he was thinking about

while sitting on top of the rocket ready to launch Apollo

11 to the moon. “Every part was made by the lowest

bidder,” was supposedly his reply. (The same quote has

been attributed to most early astronauts!)

Fiber optics are not necessarily

expensive; in fact, fiber has been used so widely because

it is the least expensive communications medium in

virtually all projects. But fiber optic projects may

require a lot of construction which makes the project

expensive. Like all other projects, it never pays to cut

corners. Planning and running the project properly is what

saves money, trying to cheapen the project. Not all jobs

should go to the lowest bidder, unless they meet all the

criteria for a qualified bidder. Likewise, one needs to

ensure that when a project starts, there are funds

available to complete the job properly, including some

extra for unplanned changes or modifications.

Commitment: Just like having

sufficient finances to compete the project, one needs a

commitment to finish the job once it is started. Changes

of management or changes in governments often lead to

confusion or even modifying a project in midstream. There

is nothing wrong with making changes based on what learns

as the project progresses; it may even involve greater

efficiency or cost savings, but arbitrary changes may

jeopardize the project's timetable, completion or even its

usefulness.

If the project is under the auspices of

a government entity, changes in administration or

management that causes changes in a project will

invariably make it more expensive and may jeopardize the

success of the entire project. Ideally, the personnel who

propose, design and plan the network should see it to

completion.

Expertise: Fiber requires

expertise and experience. It's obvious the installers need

to know what they are doing, but in reality, so must the

managers who work for the organization that is contracting

for the work. There are many instances of projects where

the managers signed off on the project when it was

incomplete or improperly installed. The only way to

properly manage a project is to understand every aspect of

it well enough to know if it is being done properly and

when it is actually complete.

Planners, designers, contractors and

installers should all be trained and certified

as well as being experienced with good references. That

holds doubly so for consultants. In many places, to be a

consultant or cabling contractor means little other than

registering as a business and advertising your services.

Some of the problems we've seen with outside services,

include consultants who took contracts, spent time on a

project, then told the customer they could not help them

with the project, but kept the money.

We have seen contractors doing shoddy

installations, ruining expensive fiber optic cable during

pulling and leaving jobs half done but getting paid

because the customer knew no better. One of the biggest

problems is subcontractors. A contractor with good

credentials gets the job but subcontracts some of the work

to a contractor who will do the work at a lower price, but

does not have the training or experience (or motivation)

to do it right. In your contract with an installer, we

recommend a clause giving the project manager

responsibility for evaluating and approving all

subcontractors.

The manager must know better to prevent

problems. FOA also has pages on what

the manager needs to know.

Patience: From concept to

acceptance, a typical OSP fiber project can take 2-5 years

and a premises project 1-2 years. It depends on the size

of the project, the time to properly design it, create

project paperwork, get permits, buy components, hire

contractors and properly install it. Proper

workmanship takes time and is not easily rushed. Saving

time generally means cutting corners and that is often the

cause of the problems encountered. Take your time, plan,

design, select, install, test and document your network

properly.

And by the way, "future proofing" is a

myth! Who would have known in 1990 how ubiquitous the

Internet would be today? How reliant we could be on

smartphones other mobile devices? How many workers would

be working remotely or using videoconferencing for

meetings? Technology moves too fast and is too disruptive

for anyone to make reliable predictions. The IBMer who

developed MRP - the original company organizational

software - used to tell everyone, "A forecast is wrong

from the moment it is made." Plan for the future, but

assume you will upgrade, change directions, etc. driven by

new tech and changes in the world around us.

- Technical

Information on FTTX From The FOA

Online Guide:

- FTTH

Introduction

- FTTH

Architectures,

- FTTH

in MDUs (Multiple Dwelling Units)

- FTTH

PON Standards, Specifications and Protocols

- FTTH

Design

- FTTH

Installation

- FTTH

Customer Premises Installation

FTTH

Network Testing

FTTH

Case Studies: Do-It-Yourself FTTH

FTTH

Project Management

Migration from GPON to 10GPON

- The

Fiber Optic Association Fiber To The Home Handbook:

For Planners, Managers, Designers, Installers And

Operators Of FTTH - Fiber To The Home - Networks

The

Fiber Optic Association Fiber To The Home

Handbook Available

in paperback or as an eBook on the Amazon

Kindle Available

direct from Amazon.com,

local booksellers and other distributors.

- Training

& Certification

Fiber

U Online FTTx Self Study Program (free)

- FOA

Certification Overview

FOA

FTTx Certification Requirements

FOA-Approved

Training Programs

Table of Contents: The

FOA Reference Guide To Fiber Optics

|