- Lennie Lightwave's

- Guide To Fiber Optics

Cable

Fiber Optic Cables

Fiber optic "cable" refers to the complete assembly of fibers, strength members and jacket. Fiber optic cables come in lots of different types, depending on the number of fibers and how and where it will be installed. Choose cable carefully as the choice will affect how easy it is to install, splice or terminate and, most important, what it will cost!

Choosing a cable - what hazards will it face?

Cable's job is to protect the fibers from the hazards encountered in an installation. Will the cables be exposed to chemicals or have to withstand a wide temperature range? What about being gnawed on by a woodchuck or prairie dog? Inside buildings, cables don't have to be so strong to protect the fibers, but they have to meet all fire code provisions. Outside the building, it depends on whether the cable is buried directly, pulled in conduit, strung aerially or whatever.

Your best bet is to contact a few cable manufacturers (two minimum, three preferred) and give them the specs. They will want to know where the cable is going, how many fibers you need and what kind (singlemode or multimode or both in what we call "hybrid" cables.) You can also have a "composite" cable that includes copper conductors for signals or power. The cable companies will evaluate your requirements and make suggestions. Then you can get competitive bids.

Since the plan will call for a certain number of fibers, consider adding spare fibers to the cable - fibers are cheap! That way, you won't be in trouble if you break a fiber or two when splicing, breaking-out or terminating fibers. And request the end user consider their future expansion needs. Most users install lots more fibers than needed, especially adding singlemode fiber to multimode fiber cables for campus or backbone applications.

Cable Types

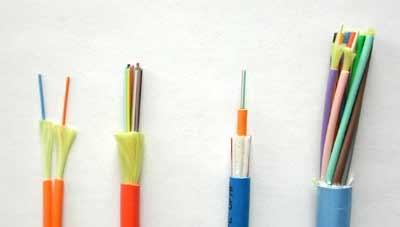

Cables (L>R): Zipcord, Distribution, Loose Tube, Breakout

Simplex and zip cord: Simplex cables are one fiber, tight-buffered (coated with a 900 micron buffer over the primary buffer coating) with Kevlar (aramid fiber) strength members and jacketed for indoor use. The jacket is usually 3mm (1/8 in.) diameter. Zipcord is simply two of these joined with a thin web. It's used mostly for patch cord and backplane applications, but zipcord can also be used for desktop connections.

Distribution cables: They contain several tight-buffered fibers bundled under the same jacket with Kevlar strength members and sometimes fiberglass rod reinforcement to stiffen the cable and prevent kinking. These cables are small in size, and used for short, dry conduit runs, riser and plenum applications. The fibers are double buffered and can be directly terminated, but because their fibers are not individually reinforced, these cables need to be broken out with a "breakout box" or terminated inside a patch panel or junction box.

Breakout cables: They are made of several simplex cables bundled together. This is a strong, rugged design, but is larger and more expensive than the distribution cables. It is suitable for conduit runs, riser and plenum applications. Because each fiber is individually reinforced, this design allows for quick termination to connectors and does not require patch panels or boxes. Breakout cable can be more economic where fiber count isn't too large and distances too long, because is requires so much less labor to terminate.

Loose tube cables: These cables are composed of several fibers together inside a small plastic tube, which are in turn wound around a central strength member and jacketed, providing a small, high fiber count cable. This type of cable is ideal for outside plant trunking applications, as it can be made with the loose tubes filled with gel or water absorbent powder to prevent harm to the fibers from water. It can be used in conduits, strung overhead or buried directly into the ground. Since the fibers have only a thin buffer coating, they must be carefully handled and protected to prevent damage.

Ribbon Cable: This cable offers the highest packing density, since all the fibers are laid out in rows, typically of 12 fibers, and laid on top of each other. This way 144 fibers only has a cross section of about 1/4 inch or 6 mm! Some cable designs use a "slotted core" with up to 6 of these 144 fiber ribbon assemblies for 864 fibers in one cable! Since it's outside plant cable, it's gel-filled for water blocking.

Armored Cable: Cable installed by direct burial in areas where rodents are a problem usually have metal armoring between two jackets to prevent rodent penetration. This means the cable is conductive, so it must be grounded properly.

Aerial cable: Aerial cables are for outside installation on poles. They can be lashed to a messenger or another cable (common in CATV) or have metal or aramid strength members to make them self supporting.

Air-Blown Fiber: Technically not a cable, but think of bundles of tubes in which bundles of special fibers can be blown after the bundles of tubes are installed. Need more fibers, blow them in. Need different fibers, blow the current ones out, blow new ones in. Can be costly for first install, but cheaper later.

Even More Types Are Available: Every manufacturer has it's own favorites, so it's a good idea to get literature from as many cable makers as possible. And check out the little guys; often they can save you a bundle by making special cable just for you, even in relative small quantities.

Cable Design Criteria

Pulling Strength: Some cable is simply laid into cable trays or ditches, so pull strength is not too important. But other cable may be pulled thorough 2 km or more of conduit. Even with lots of cable lubricant, pulling tension can be high. Most cables get their strength from an aramid fiber (Kevlar is the duPont trade name), a unique polymer fiber that is very strong but does not stretch - so pulling on it will not stress the other components in the cable. The simplest simplex cable has a pull strength of 100-200 pounds, while outside plant cable may have a specification of over 800 pounds.

Water Protection: Outdoors, every cable must be protected from water or moisture. It starts with a moisture resistant jacket, usually PE (polyethylene), and a filling of water-blocking material. The usual way is to flood the cable with a water-blocking gel. It's effective but messy - requiring a gel remover (use the commercial stuff - it's best- -but bottled lemon juice works in a pinch!). A newer alternative is dry water blocking using a miracle powder - the stuff developed to absorb moisture in disposable diapers. Check with your cable supplier to see if they offer it.

Fire Code Ratings: Every cable installed indoors must meet fire codes. That means the jacket must be rated for fire resistance, with ratings for general use, riser (a vertical cable feeds flames more than horizontal) and plenum (for installation in air-handling areas. Most indoor cables us PVC (polyvinyl chloride) jacketing for fire retardance. All premises cables must carry identification and flammability ratings per the NEC (National Electrical Code) paragraph 770. These ratings are:

| NEC Rating | Description |

| OFN | optical fiber non-conductive |

| OFC | optical fiber conductive |

| OFNG or OFCG | general purpose |

| OFNR or OFCR | riser rated cable for vertical runs |

| OFNP or OFCP | plenum rated cables for use in air-handling plenums |

| OFN-LS | low smoke density |

Cables without markings should never be installed as they will not pass inspections! Outdoor cables are not fire-rated and can only be used up to 50 feet indoors. If you need to bring an outdoor cable indoors, consider a double-jacketed cable with PE jacket over a PVC UL-rated indoor jacket. Simply remove the outdoor jacket when you come indoors and you will not have to terminate at the entry point.

Choosing A Cable

With so much choice in cables, it is hard to find the right one. The table below summarizes the choices, applications and advantages of each.

| Cable Type | Application | Advantages |

| Tight Buffer | Premises | Makes rugged patchcords |

| Distribution | Premises | Small size for lots of fibers, inexpensive |

| Breakout | Premises | Rugged, easy to terminate, no hardware needed |

| Loose Tube | Outside Plant | Rugged, gel or dry water-blocking |

| Armored | Outside Plant | Prevents rodent damage |

| Ribbon | Outside Plant | Highest fiber count for small size |

Pulling Fiber Optic Cable

Installation methods for both wire cables and optical fiber cables are similar. Fiber cable can be pulled with much greater force than copper wire if you pull it correctly. Just remember these rules:

Do not pull on the fibers, pull on the strength members only! The cable manufacturer gives you the perfect solution to pulling the cables, they install special strength members, usually duPont Kevlar aramid yarn or a fiberglass rod to pull on. Use it! Any other method may put stress on the fibers and harm them. Most cables cannot be pulled by the jacket. Do not pull on the jacket unless it is specifically approved by the cable manufacturers and you use an approved cable grip.

Do not exceed the maximum pulling load rating. On long runs, use proper lubricants and make sure they are compatible with the cable jacket. On really long runs, pull from the middle out to both ends. If possible, use an automated puller with tension control or at least a breakaway pulling eye.

Do not exceed the cable bend radius. Fiber is stronger than steel when you pull it straight, but it breaks easily when bent too tightly. These will harm the fibers, maybe immediately, maybe not for a few years, but you will harm them and the cable must be removed and thrown away!

Do not twist the cable. Putting a twist in the cable can stress the fibers too. Always roll the cable off the spool instead of spinning it off the spool end. This will put a twist in the cable for every turn on the spool! If you are laying cable out for a long pull, use a "figure 8" on the ground to prevent twisting (the figure 8 puts a half twist in on one side of the 8 and takes it out on the other, preventing twists.) And always use a swivel pulling eye because pulling tension will cause twisting forces on the cable.

Check the length. Make sure the cable is long enough for the run. It's not easly or cheap to splice fiber and it needs special protection. Try to make it in one pull, possible up to about 2-3 miles.

Conduit and Innerduct: Outside plant cables are either installed in conduit or innerduct or direct buried, depending on the cable type. Building cables can be installed directly, but you might consider putting them inside plenum-rated innerduct. This innerduct is bright orange and will provide a good way to identify fiber optic cable and protect it from damage, generally a result of someone cutting it by mistake! The innerduct can speed installation and maybe even cut costs. It can be installed quickly by unskilled labor, then the fiber cable can be pulled through in seconds. You can even get the innerduct with pulling tape already installed.

Cable Plant Hardware - fitting the pieces of the puzzle together!

These various enclosures, cabinets, racks and panels are used to protect and organize splice and termination points. The network designer should know the type of network, support systems, the routes to be taken. Then the connection/splice locations can be determined and the hardware planned.

There are lots of rules to follow, of course (the EIA/TIA 569 has something to say about all this).

Here are some examples of fiber optic hardware:

Breakout kits: They allow you to separate and protect individual fibers in a loose tube cable so it can be terminated.

Splice enclosures - for long cable runs outside, the point where cables are spliced, sealed up and buried in the ground, put in a vault of some kind or hung off a pole.

Splice panels- connect individual fibers from cables to pigtails

Patch panels - provides a centralized location for patching fibers, testing, monitoring and restoring cables.

Racks and cabinets: enclosures for patch panels and splice panels. Usually these also include cable management - without this the cables start looking like spaghetti flying everywhere in a short time!

There are tons of hardware and tons of manufacturers who make them. Be sure to choose panels that have the connections behind locked doors, since the biggest problem we see is connectors broken by people messing around in communications closets! Fiber doesn't need maintenance or inspection. Lock 'em up and only unlock it when you have to move something!